- Products 2025/09/03 UP

-

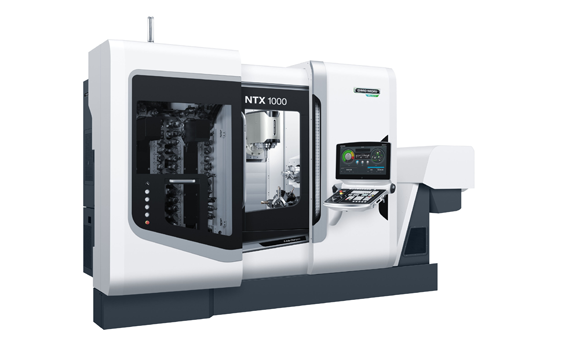

Space-Saving Integrated Mill Turn Center for Automation

The NTX 1000 3rd Generation is equipped with the direct drive motor on the B-axis, achieving high-precision, simultaneous 5-axis machining. The model is suited to high-precision machining of complex-shaped workpieces in various fields including the medical, aircraft and automotive industries.

Despite the smallest footprint of 10.6 cm2 in its class, the model features a wide machining chamber that can handle workpieces with a length of up to 800 mm and a diameter of up to 430 mm.

The model meets the need for automation systems such as an in-machine traveling robot and a workpiece unloader.

Main Machine Specifications

*Scroll to see more.

| Max. turning length | Max. turning diameter | Max. spindle speed | Turn-mill spindle max. speed | Tool storage capacity | |

|

|

Capto C5: 800 mm、 Capto C6: 780 mm |

Turn-mill spindle: Φ430 mm、 Turret 2: Φ274 mm |

6,000 mm-1 | 20,000 mm-1 *OP | 38, 76, 114 |

※The actual values may differ from those specified in the catalogue, depending on the optional features and peripheral equipment.