- Products 2020/10/08 UP

-

Protect Spindle by Emergency Stop

MPC monitors vibrations with the acceleration sensor attached to the spindle. When detecting abnormal vibration values, MPC stops the spindle to minimize the damage to the machine. It is also equipped with the function to diagnose the condition of spindle bearings. As the function detects wear of the bearings in advance, it is also effective as preventive maintenance.

Main Applicable models

- DMU eVo series

- DMC monoBLOCK series

- DMU/DMC(FD)duoBLOCK series

- NVX、NHX、NTX series

Background of Development

The increasing popularity of unmanned operation without constant monitoring by the operator, alongside the need for minimizing interference-caused damage, early detection of abnormalities, prevention and early finding of indicators cause many new challenges.

DMG MORI developed MPC as solution to these challengers. MPC stops machine operation, when its high-precision acceleration sensor detects early bearing malfunctions or abnormal vibrations, and automatically exchanges tools when detecting breakage.

Unique Selling Points

1. Detection of abnormal vibrations

When the high-precision acceleration sensor on the spindle detects abnormal vibrations, it stops rotation and feed to minimize the damage to the machine.

2. Monitoring of processes

MPC monitors vibrations during machining by setting up the limit value of spindle vibration beforehand. When it records out of range, it stops the spindle motion and feed.

Moreover, when MPC connects to the tool management function and commands the same group of tools, MPC can call another tool of the same group to exchange them for automatic recovery in case of tool breakage.

3. Preventive Maintenance

MPC analyzes vibrations detected by the acceleration sensor to diagnoses wear of spindle bearings. This enables operators to predict when maintenance is necessary in advance.

As the spindle can be repaired or replaced to prevent emergency problems before they happen, shop floor production can be done as planned.

4. Operability

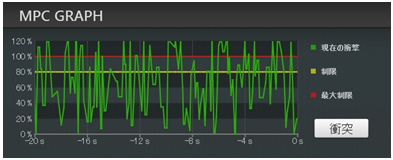

With MPC, operators can check the following three conditions on CELOS, an HMI: “MPC Peak Meter” that indicates the spindle unbalance and vibration levels during machining; “MPC Graph” that shows immediate vibration levels and limited values; and “MPC Diagnostics” that displays the bearing status and cumulative record of vibrations.

MPC PEAKMETER

- Current values of unbalance and vibration

MPC GRAPH

- Vibration level of immediate 20 seconds and the limited values

MPC DIAGNOSTICS

- Bearing conditions

- Cumulative record of vibration