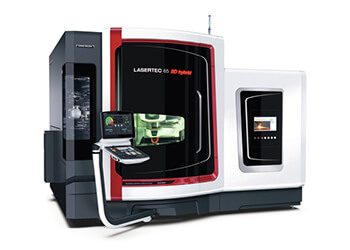

HSC Series

-

-

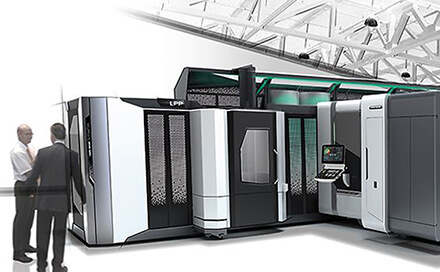

DMU eVo Series

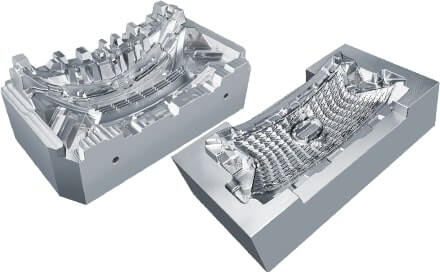

Higher surface quality by the 5-axis control machine ensuring

high dynamic performance with the linear drive

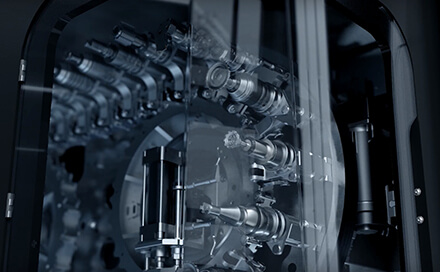

What is linear drive?

A linear drive is a linear motion drive system using a linear motor that generates a driving force by magnetic attraction and repulsion.

Compared with a ball screw drive system that uses a rotary motor, it is lightweight with a fewer number of parts. As a linear drive enables non-contact drive by use of magnetic force, it is capable of accelerating and decelerating quickly, moving smoothly, and making a stop accurately.

With a non-contact drive mechanism, it is possible to reduce parts wear and simplify maintenance as well as eliminating backlash to achieve higher positioning accuracy and stable machining.

A linear drive is a drive system most suitable for machine tools requiring precision machining.