| Material | S55C |

|---|---|

| Size | 1,570×950×578 mm (61.8×37.4×22.8 in.) |

| Machining time | 478.8 hours |

| Max. mass | 5.8t |

| Cutting oil | Water-miscible coolant |

Bridge-type, 5-sided / 5-axis machine with high accuracy and dynamic performance

Machining time reduced by 25%

Time from material loading to sample completion

Time for electrical

discharge-related processes reduced by 136 hrs.

Neither electrical discharge machining nor electrode production required (Design + CAM + Cutting)

Polishing time reduced by 14 hrs.

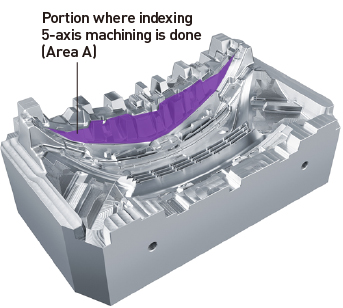

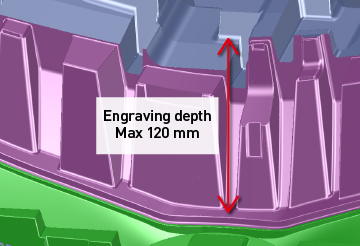

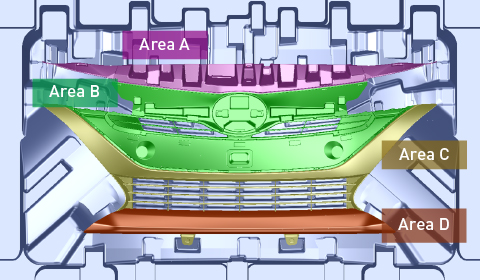

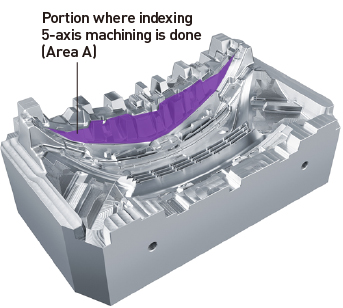

Areas A & D

POINT

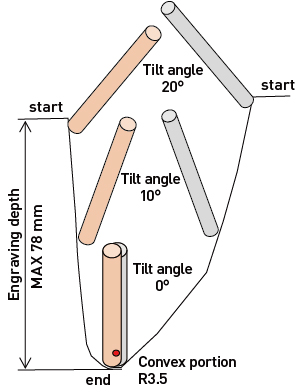

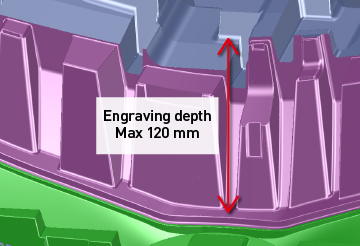

From electrical discharge machining to direct engraving (indexing 5-axis machining)

POINT

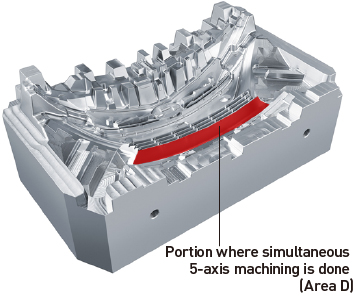

Simultaneous 5-axis machining with a single tool