CNC machine tools

DMG MORI provides cutting-edge machine tools that meet the diverse needs of a wide range of industries including automotive, die and mold, aerospace, semiconductor and medical sectors.

5-axis / Multi-axis Machines

Overturn the conventional wisdom about part machining

The DMG MORI’s 5-axis control machines boast overwhelming milling performance and operability thanks to some 120 years of the development and production experience in Europe. 5-axis control machines capable of multi-faceted indexing can complete machining in one clamp, which as a result reduces the frequency of setups and simplifies/eliminates fixtures to drastically shorten process times. The machine also ensures highly accurate machining, which was impossible to perform with 3- and 4-axis machine, by having tools approach from optimal angles with its rotary axes.

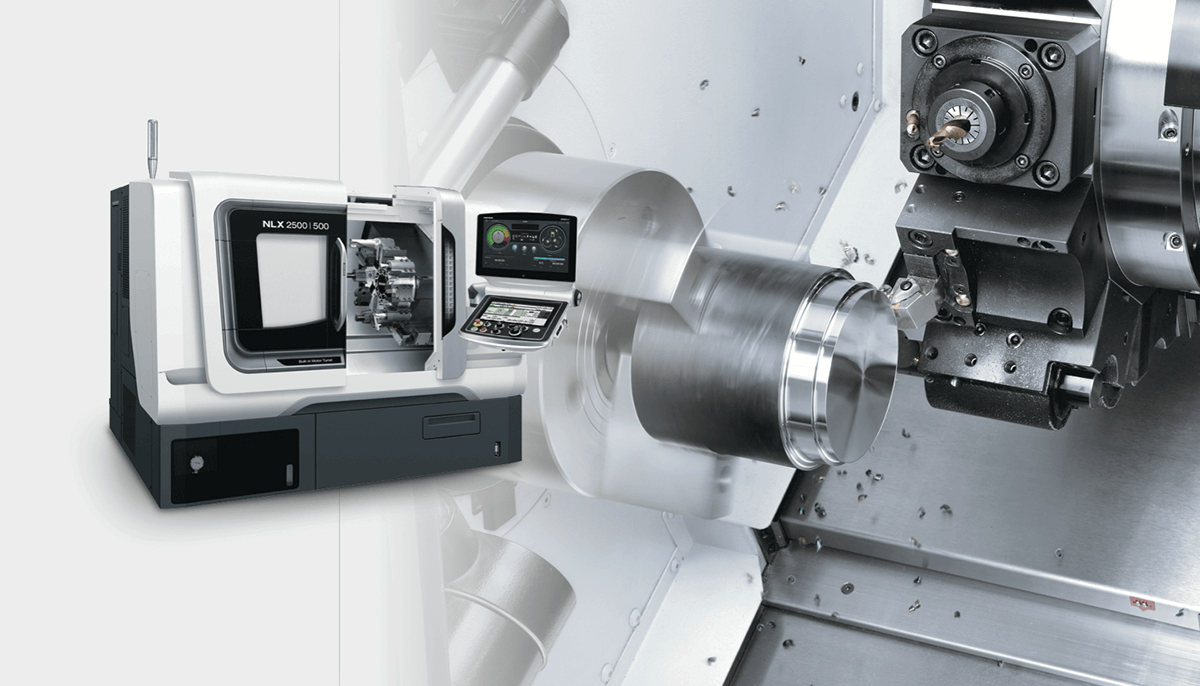

A mill-turn machine, as the name implies, completes machining, which was conventionally done on multiple machines, on one machine with no operator assistance. High machining performance achieved by a combination of the turning center and machining center features can bring customers a great deal of profits by drastic reduction in production lead times and efficient process integration in high-mix, low-volume production and mass-production.

PICKUP

-

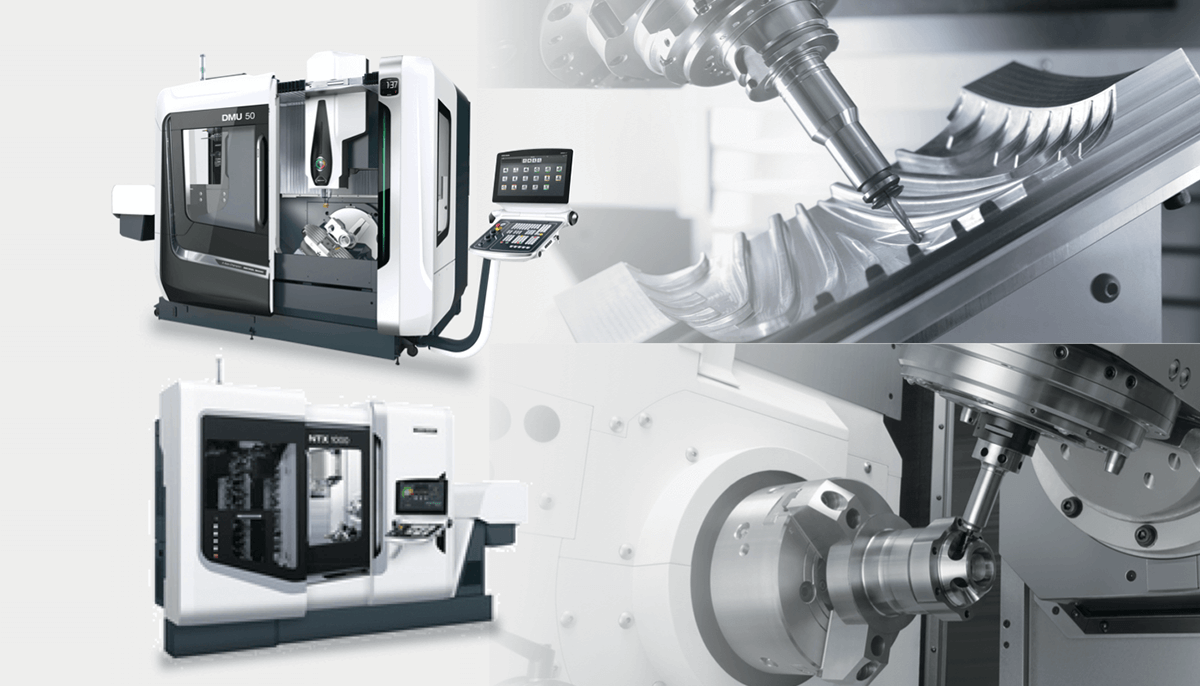

DMU 50 3rd Generation

Compact universal machining centre of the 3rd generation for 5-axis simultaneous machining

-

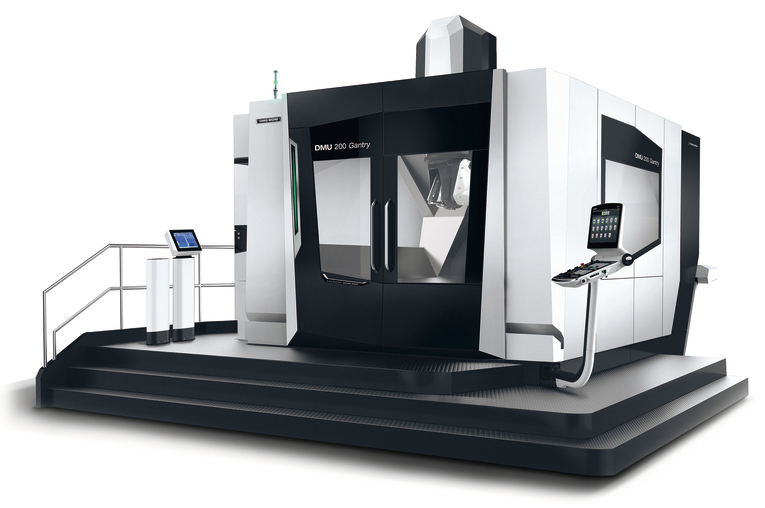

DMU 200 Gantry

5-axis machines with best-in-class accuracy and high-speed cutting

-

NTX 500

Space-Saving Integrated Mill Turn Center for Automation

-

NTX 3000 | 3000 2nd Generation

The highest dimensional, volumetric and surface accuracy istance between centers 3,000 version for long shaft processing

Turning Centers

Origin of DMG MORI

DMG MORI began manufacturing machine tools in 1958, and since then the company gained fame as “Lathe manufacturer Mori Seki” by the thoroughgoing differentiation strategy that distinguishes them from other manufacturers inside and outside of Japan. GILDEMEISTER, the predecessor of DMG MORI AG, has a history of some 150 years of manufacturing turning centers. The DMG MORI’s lathes, currently equipped with milling capability as well as its characteristic turning capability ensured by BMT (Built-in Motor Turret) and moving axes, have evolved into high-rigidity, high-accuracy turning centers for machining a wide range of workpieces.

PICKUP

-

ALX 1500 | 300

Solution-based Standard Machine for Every Shop Floor

-

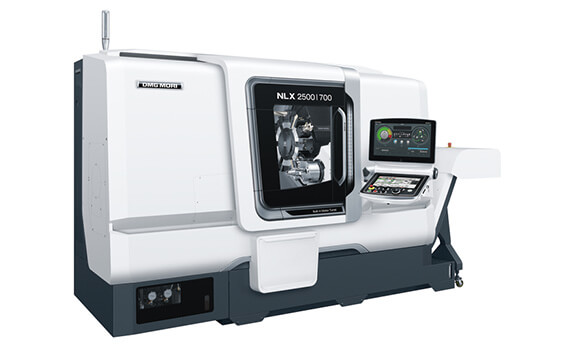

NLX 2500 | 700

10-inch Chuck Size Turning Center with Varieties of Specifications

-

NRX 2000

Ideal for mass production machining of flanges for automobiles

-

CTV 250 / 250 linear

Vertical Lathe for Automation that Achieves High-productivity

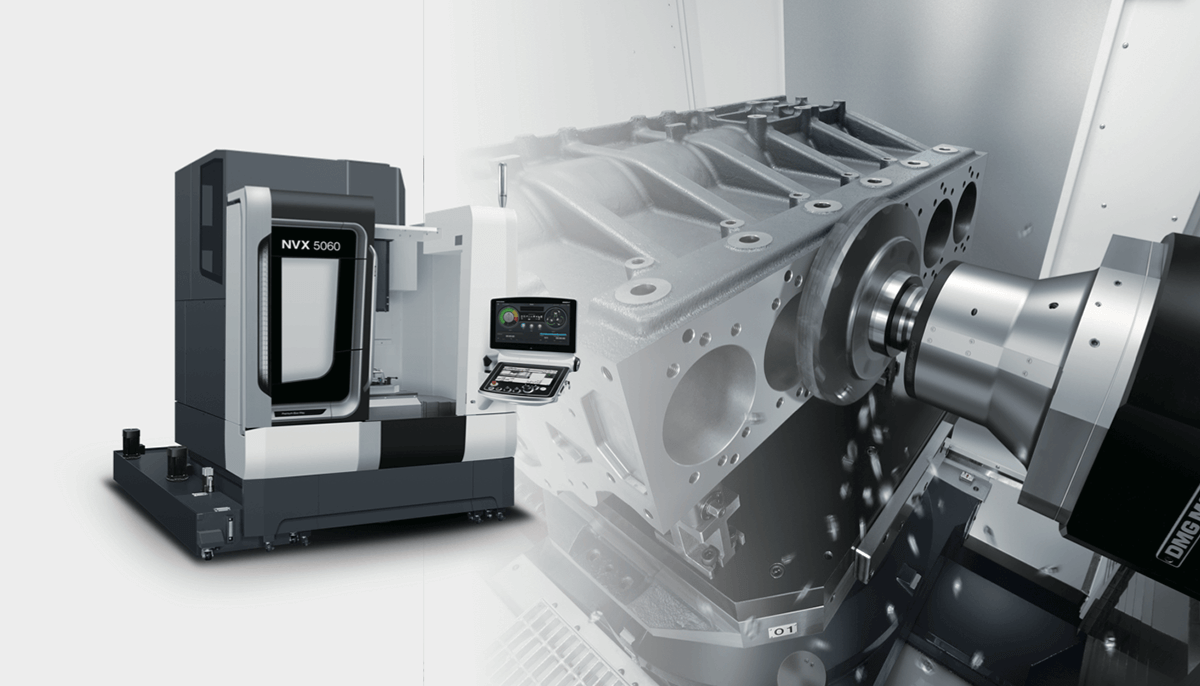

Machining Centers

Meeting the needs of every field

A machining center is a machine tool to perform various types of machining by changing rotary tools for milling, hole machining, boring, and tapping with an automatic tool changer. DMG MORI offers vertical and horizontal machining centers that can work with robot systems and automation systems to respond to diversifying customer needs.

PICKUP

-

NVX 5080 2nd Generation

Best Surface Quality Highest Accuracy for Any Machining Operations

-

CMX 600 V

Solution-based Machines for Every Shop Floor

-

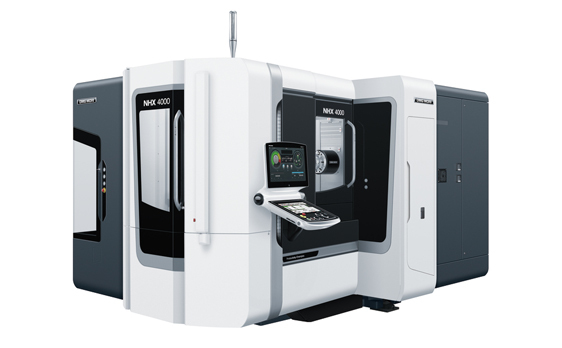

NHX 4000 3rd Generation

Cutting-edge High-speed and High-precision Machining beyond Imagination

-

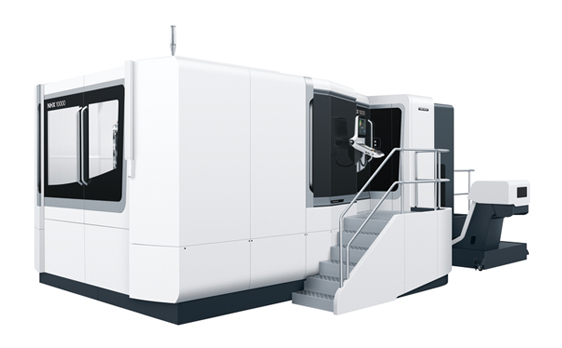

NHX 10000

High-speed Heavy-duty Cutting of Large Workpieces

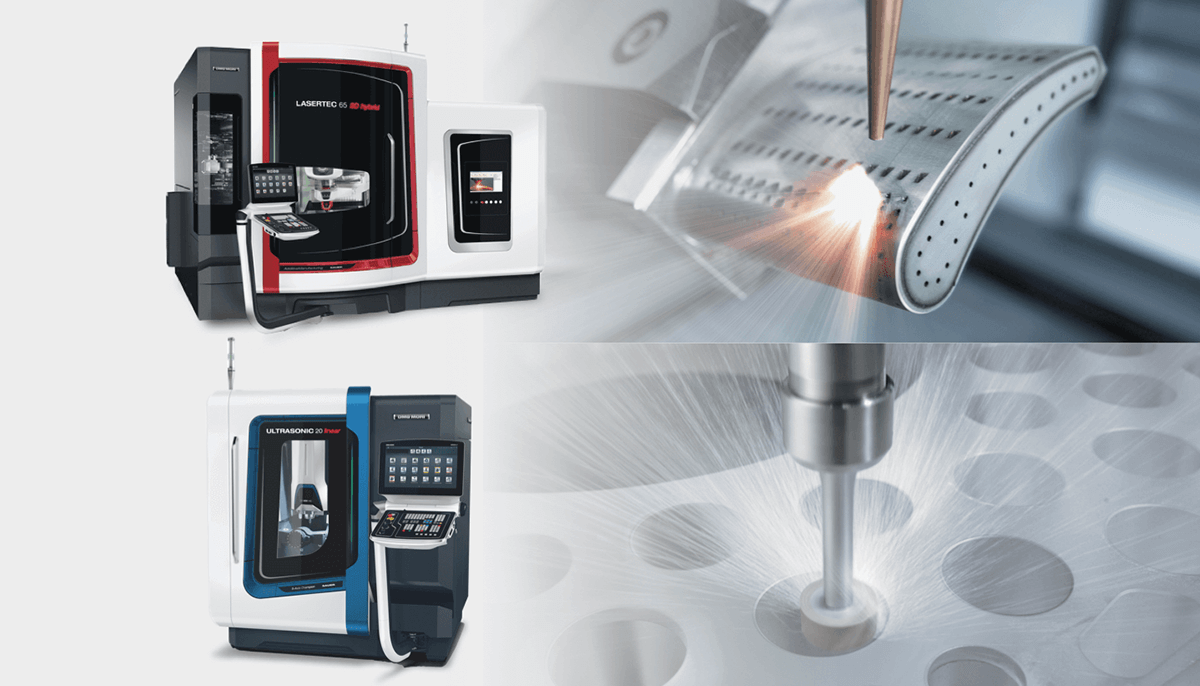

ULTRASONIC / LASERTEC

Innovative cutting-edge technology

An ultrasonic machine is capable of machining advanced materials which are generally considered difficult to cut into complex-shaped forms in an efficient manner. Cutting resistance can be well controlled compared to the existing machine because tool rotation is synchronized with ultrasonic vibration in the Z-axis direction.

A laser machine is capable of forming, micro machining, power drilling and manufacturing of precision tools. Any types of metals and new materials can be machined with high efficiency at low costs.