- Products 2024/10/02 UP

-

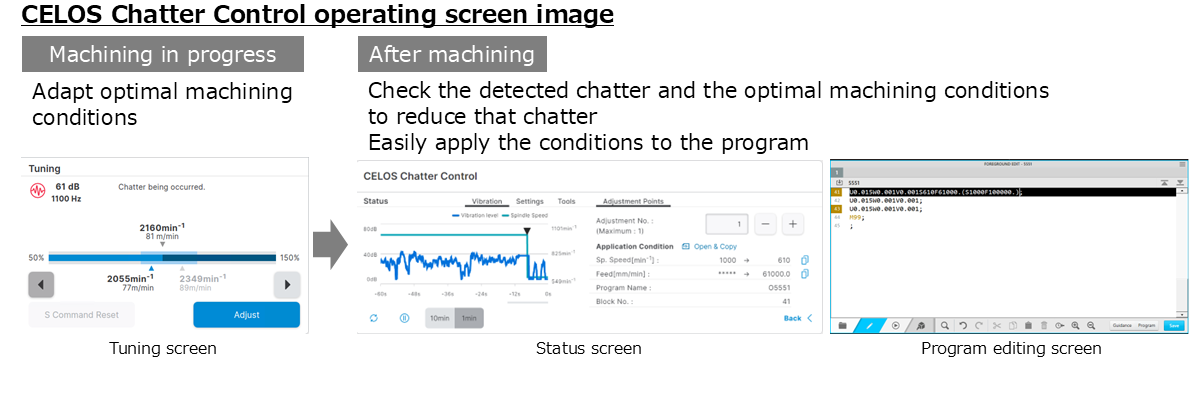

Control Vibrations for OptimalMachining Conditions

CELOS Chatter Control / MVC, one of the “Monitoring” functions of Technology Cycles, supports the optimal machining by controlling vibrations. The acceleration sensor mounted in the spindle detects the vibration, and the DMG MORI-developed built-in software calculates the spindle speed to suppress the vibration based on the vibration frequency and displays several machining conditions on the screen.

Main Applicable models

CELOS Chatter Control

- INH series, NTX 500

MVC

- NVX, NHX, NTX series

Background of Development

Finding the optimal machining condition to control chatter highly relies on experience of skilled engineers. For engineers with less experience, it usually takes longer time due to a trial-and-error adjustment. The use of end mills with variable pitch and variable lead can be one of the solutions as chatter is less likely to occur to them, whereas the disadvantages are that they are expensive and have few variations of types. So DMG MORI has developed “CELOS Chatter Control/MVC” that automatically calculates the machining condition that is capable of controlling chatter.

Unique selling points

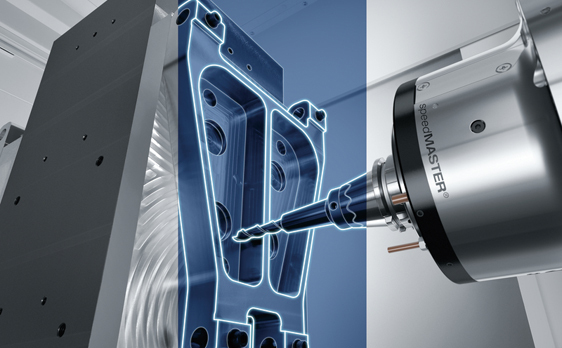

1.Highly accurate chatter detection

Conditions in which vibration is generated vary depending on the material and shape of the workpiece and type of the tool in use. Under various conditions, CELOS Chatter Control / MVC detects vibrations by using the high-accuracy acceleration sensor mounted on the spindle, and calculates the optimum machining conditions. CELOS Chatter Control / MVC is particularly suitable for machining using an end mill, and is also useful for improving the machining conditions in the existing programs.

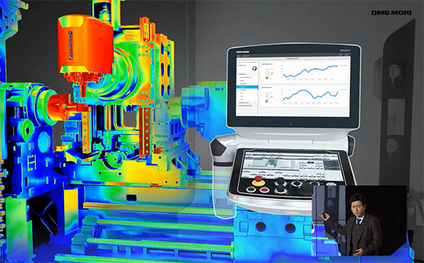

2.Operability

CELOS Chatter Control / MVC adopt a simple, user-friendly interface and can be operated via a touch screen panel. They automatically detect chatter and display the optimal spindle speed for reducing the chatter. Using touch operations, users can easily select and adapt the optimal machining conditions indicated by CELOS Chatter Control / MVC. Even with no expertise about vibration suppression, anyone can easily control chattering.

The adapted machining conditions can be effortlessly reflected in NC programs.

3.Significantly reduces work when chattering occurs

CELOS Chatter Control / MVC contributes to reduction of time for test machining and improvement of machine operating time since it quickly determines the machining conditions to suppress vibration using the acceleration sensor and the DMG MORI-developed built-in software.