- Products 2024/01/11 UP

-

Machining of Various Gears

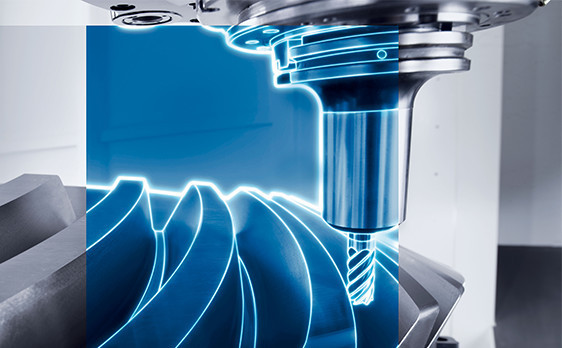

With DMG MORI gearMILL, gear machining can be performed with general-purpose end mills or cutters on a single 5-axis machining center, which used to be done on more than one machine including a specialized machine using specialized tools such as hob cutters or pinion cutters. Operators can easily create a series of programs that include setting of gear specifications and tools to be used on a PC, achieving machining of various types of gears efficiently.

Main Applicable models

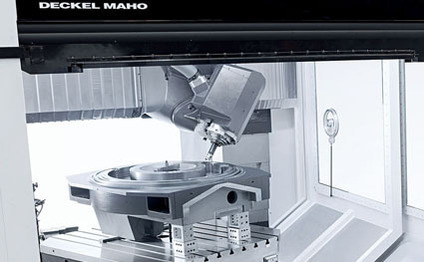

- DMU/DMC monoBLOCK series

- DMU/DMC(FD)duoBLOCK series

- Double column series

- NHX, NTX series

Background of Development

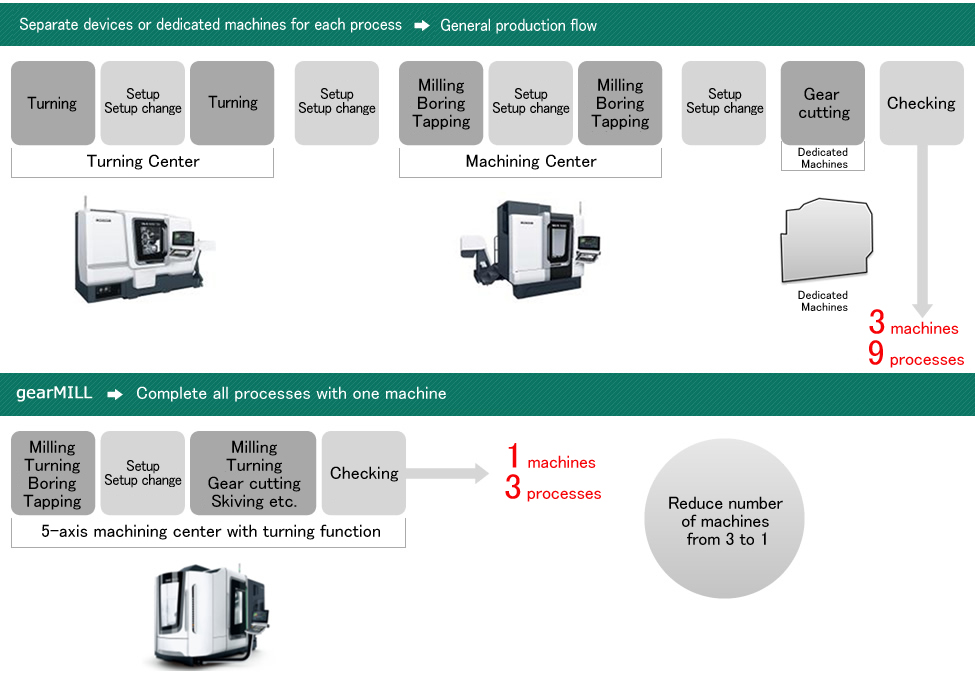

Since various gears are applied to power transmission systems for construction machinery, aircrafts, marine vessels, and wind-power generation, there is an endless demand for high efficiency production. Additionally, there arises a demand for high-accuracy, light-weight, and compact high-functionality gears capable of realizing highly efficient, low-vibration, and low noise power transmission. Gears are generally produced with more than one machine tool including a specialized machine such as a hobbing machine and a broaching machine. The issues are that it takes time to complete a whole machining process because each process has an idle time, and that the production calls for an investment in multiple machines. DMG MORI has developed DMG MORI gearMILL in order to tackle such issues and achieve highly accurate gear machining on a single machine.

Unique Selling Points

1.Versatility

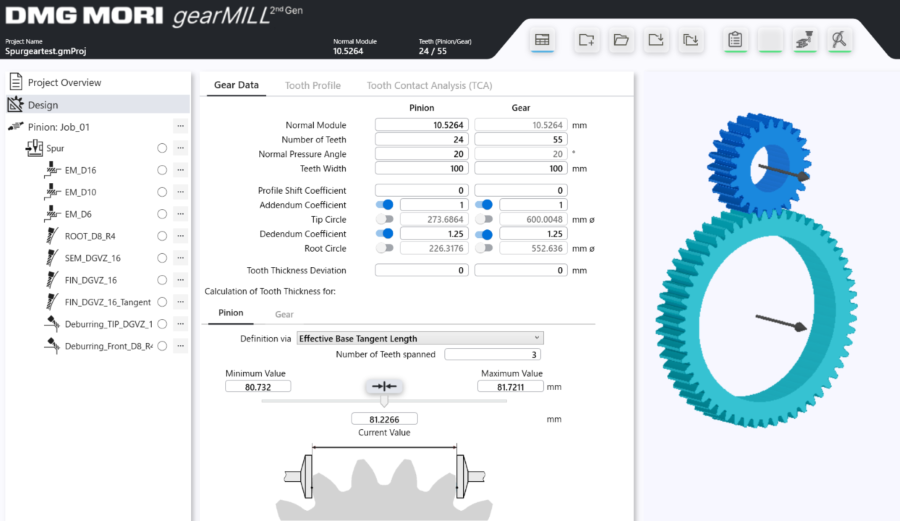

DMG MORI gearMILL can be used on a PC* like CAM software, and supports modeling, generation of tool paths and measurement. Setting gear specifications and tools to be used generates tool paths of various gears including double-helical gears, bevel gears (straight gears, helical gears, spiral gears) and hypoid gears in addition to spur gears and helical gears. The Technology Cycle can flexibly handle various types of machining as it uses general-purpose tools instead of expensive specialized tools. DMG MORI gearMILL is available on most of the DMG MORI 5-axis machines.

- *Windows 10 (64 bit)

gearMILL2.0 interface

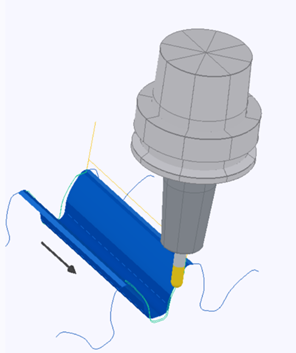

2.Process Integration

Gear machining generally requires more than one machine, for example, a turning center and a machining center, and a gear machine. With DMG gearMILL, a single 5-axis machine can complete a workpiece, which contributes to reducing a number of machines. Additionally, it automates the chamfering process that was mostly performed by hand. What’s more, elimination of setups shortens setup and idle time, reducing the lead time from the product material state to its completed state. Productivity was drastically improved per unit area.

Chamfer function

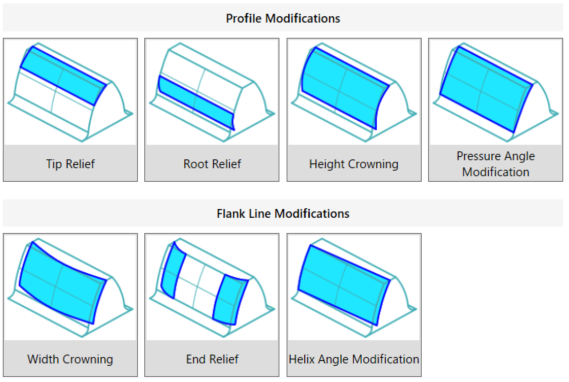

3.Reduction in Programming Time and Gear Tooth Adjustment Time

Operators can set information such as gear forms, gear mesh, and tool paths while checking the graphics on a PC. As inputting parameters does not require any special skills, the programs can be created in a short time. Additionally, the time for checking and adjusting the gear mesh can be shortened since there are various gear tooth adjustment settings available.

Various gear tooth adjustments

Process Integration and Reduced Machining Time