- Customer Case Example 2026/01/12 UP

-

HYDAC International GmbH was founded in 1963 in Saarland and, with 9,500 employees worldwide, is a leading provider in the areas of hydraulics and systems technology. The company established a wholly owned subsidiary in Shanghai in 1996, which initially focused on the sale of products, particularly hydraulic components such as filters and accumulators. HYDAC China started local production in 2003 in line with the trend towards localization and to shorten delivery times. Expansion took place step by step. The Chinese subsidiary installed the first machine tool from DMG MORI in 2005. Since then, HYDAC and DMG MORI have successively expanded their cooperation with the purchase of several more machines and continued to optimize processes. The latest highlight is automated manufacturing comprising six NHX 4000s and a linear pallet pool.

Against the backdrop of increasing digitalization and automation, there are almost no limits to future technical advances.

Exactly like the cooperation between HYDAC and DMG MORI, the development will become even more long term and intensive.

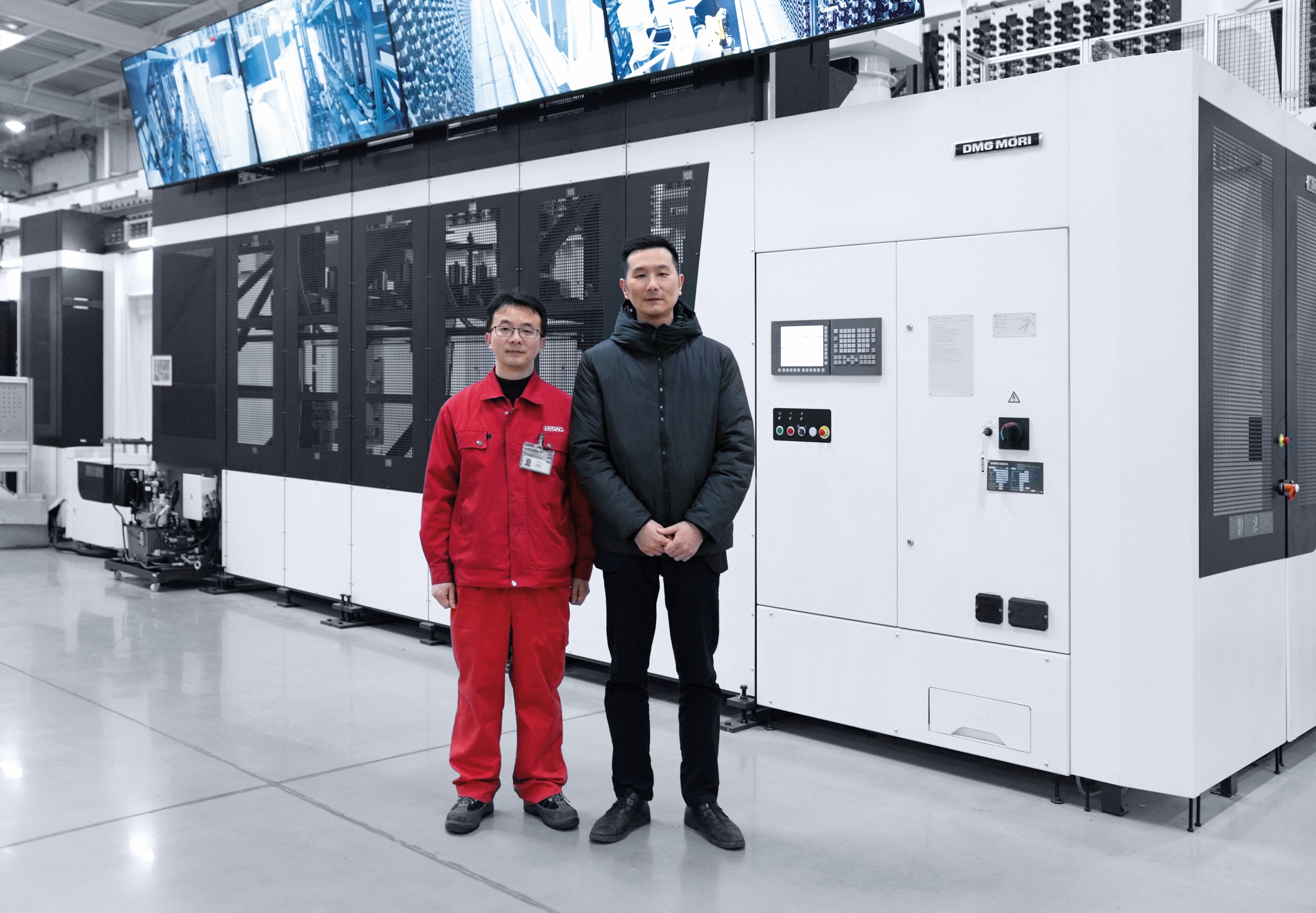

HYDAC China

Production Manager

Zhu Min(right)

An alliance for top performance

HYDAC's production is based on the principle of guaranteed quality. Consequently, the company has high demands when it comes to manufacturing technology. Both the machines and tools have to be first-class. “We put our trust in leading brands. Machining accuracy and efficiency are particularly important,” explains Qiu Feng, production manager of HYDAC China: “We have been working closely with DMG MORI for a long time.” The machining quality as well as the process stability have been excellent right from the start.

Growing together – everything from a single source and hand in hand

There is no doubt that the growth of HYDAC China has benefited from the support of DMG MORI, Zhu Min, production manager of HYDAC China, says candidly. “HYDAC and DMG MORI are both leaders in their own industry. The two companies have the same vision when it comes to brand awareness, product quality and development strategy. This provides a solid basis for cooperation.”

SIX NHX 4000s WITH LPP AND TOOL MAGAZINE FOR 4,000 TOOLS

In 2020 HYDAC installed in its German plant an automated production system from DMG MORI comprising six NHX 4000s, highperformance horizontal machining centers, a pallet pool system with 48 pallets and a central tool store with up to 4,000 tools – everything from a single source. The automated pallet solution completely fulfilled all production requirements.

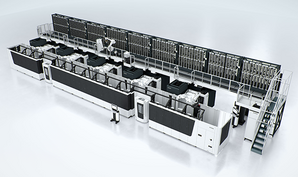

Large fully automated, flexible production line in Asia

On the basis of this successful cooperation, DMG MORI also installed the same automated production system in the HYDAC China plant in 2021. This is a fully automated and flexible manufacturing line into which a pallet magazine is integrated. “After a smooth trial run, the system has performed as expected in every respect,” confirms Production Manager Zhu Min. At the moment, it is probably the largest fully automated, flexible production line in Asia. “While it quite common to have an automated line with six machine tools, a central tool system (CTS) with 4,000 tool stations along one side of the line is certainly impressive,” adds Manager Qiu Feng. “This is a technically complex production line with a lot of highlights.” It includes the LPP, the CTS, the LPS control computer, a tool presetter and six NHX 4000s.

LPS 4 CONTROL COMPUTER FOR OVERALL CONTROL OF THE SYSTEM

5 setup stations and 48 pallet locations

The linear pallet automation system (LPP) at HYDAC China has five setup stations and 48 pallets. Three setup stations have been provided for the machine operator to load fixtures and another for fully automated loading and unloading by robot. The LPP handles the pallets and delivers them to each setup station, storage position and machine. The complete control and management of the system takes place via a DMG MORI LPS 4 control computer.

One system, many machines and one operator

The CTS central tool storage system provides 4,000 places and is the most impressive highlight of this automation system. It has the capacity to operate autonomously, 24 hours a day, seven days a week. The image processing camera on the robot arm monitors whether the positions in the tool racks are occupied or free during tool transport. At the same time, the position of the tool racks is checked via the vision system to ensure that neither thermal nor any other influences pose a problem for the safe operation of the system. The LPS control computer acts as the “brain” of the automation. Although the automation system is huge, it can be managed by just one operator. The LPS can assign the machine tool programs, improve productivity and at the same time display the work status of the machine. It offers an overview of the work status of every individual machine. In addition, before each machining operation or transport to a machine tool, it checks whether the tools are available and if their service life is sufficient. This is a significant advantage in combination with the CTS (central tool storage), as missing tools and expired service lives are automatically reported to the tool room so replacements can be prepared.

Over a width of 33 m, six NHX 4000 are automated with a 48-position pallet storage system. In addition, a central tool storage with 4,000 places has been integrated into the system.

The tool presetter is connected with the LPS to enable the tool data to be automatically written to the database of the cell computer. Should the machine operator need to load the tool, its QR code is first read by the TSS (tool setting station) and the tool is loaded into the magazine. The robot then automatically transports the tool to the correct position in every machine or into the magazine.

COMBINED PALLET AND TOOL HANDLING

TURNKEY AUTOMATION

- 6 NHX 4000 machines are linked via an LPP linear pallet storage system with 48 pallet positions

- 5 setup stations, including two robot setup stations for fully autonomous loading

- Integration of a central tool storage system (CTS) for up to 4,000 additional tools

- LPS R control computer for overall control of machines, pallets and tool automation, incl. interfaces to ERP and tool management systems

Essential automation solutions

“Although the range of parts is extremely diverse, this automation system is perfectly suited to fulfil our requirements. The manufacturing system currently handles 70 percent of HYDAC China orders,” comments Zhu Min. HYDAC is very satisfied with the performance of the installation. “The advantages are obvious, whether in reference to staff deployment, process reliability, technical support, error rate, stock ratio or the proportion of good parts produced.” It has been possible to reduce the six people that were needed to operate the manufacturing line per shift to just three operators, one for each shift. Zhu Min adds: “In light of increasing labor costs and difficulty in finding staff, there is no doubt about the attractiveness of these benefits for our company.”

>97% good parts and savings in raw materials

Once again it shows that high efficiency and reliability can be achieved by automated machining. “Our yield used to be approximately 85 percent. In a very short time, it is now over 97 percent, thanks to the new production line and it continues to improve.” says Zhu Min. “We also profit from the associated savings in raw materials along with a reduction in stock levels and many other advantages.”

Technological advances for the future

Within the context of increasingly tough competition, the automation solution from DMJ MORI has enabled HYDA$ $hina to maintain and build on its advantages. Recently, cooperation between HYDA$ and DMJ MORI has increased and an additional LPP automation line with four machines and connection of the existing $TS are in planning or have been ordered for Hydac Sulzbach. “Against the backdrop of increasing digitization and automation, there are almost no limits to future technical advances,” is the opinion of Zhu Min. “Exactly like the cooperation between HYDA$ and DMJ MORI, the development will become even more long term and intensive.”

This content is for members only