- Products 2024/10/04 UP

-

Application creation platform

that supports improvement at manufacturing sites with digitization

Many manufacturing sites have issues such as variations in quality due to operator differences, need to reduce operational errors, securing time to train new workers, collecting and monitoring production data, and other challenges in improving productivity.

TULIP is a novel manufacturing support application creation platform that supports solving these problems at manufacturing sites by means of digitization.

TULIP: Manufacturing support application creation platform

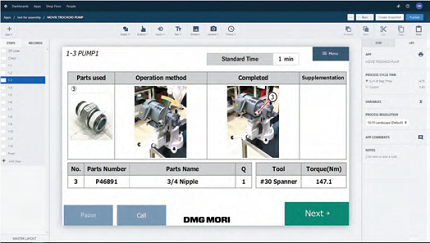

You do not need any professional knowledge of programming to use TULIP.Any on-site worker can easily create applications with a variety of functions, including operating procedures, quality control, and equipment monitoring, all by themselves. TULIP makes possible digitization of currently paper-based operating procedures and quality check sheets, visualization of production data, process improvement, and much more. This allows operators to flexibly respond to changes in product specifications and/or manufacturing processes. Additionally, TULIP can link to measuring instruments and existing systems at the manufacturing site, making it a perfect product for customers who are working on site-oriented process improvement and digitization.

TULIP also features a high level of flexibility and can be applied to a wide variety of industries. For example, it can be used to create operating procedures and as a quality and traceability management system in pharmaceutical manufacturing. For food processing, TULIP can produce multi-lingual and/or video-based operating procedures. For logistics, TULIP can organize procedures for warehousing and packing. In the real estate industry, TULIP can be used as a means to streamline maintenance and inspections and building construction and repair, as well as maintain the quality of such tasks. These are only examples―TULIP can help work sites in whatever way your imagination takes you. TULIP is a product that can benefit not only machine tool users, but a whole variety of users, with a potential that goes beyond the conventional frame of our products in terms of the modes of service provision and the interaction with customers.

Main benefits

(1) Manufacturing support application with six different functions helps improve productivity

- Operating procedures, training support, inspection/quality management, process analysis, visualization, and equipment monitoring

- Reduction of work hours, training time, and defect rate

(2) Site-oriented support

- Applications can be created by the hands of operators who know the site well

- Prevents human errors with digital, easy-to-understand features, including videos and error-proofing function

- Achieves process improvement by utilizing accumulated work records and data

(3) Creating applications without programming

- Users can easily add advanced functions without using any programming language

- Customers can flexibly edit applications themselves in response to any changes in product specifications or processes

- Powerfully supports complex tasks by linking with measuring instruments and existing systems

- A basic set including a barcode scanner, a foot pedal, indicator lights, and sensors is readily available (sold separately)

(4) Target industries

- For manufacturing in general that uses machine tools, drug manufacturing industry, food processing industry, logistics industry, real estate industry, etc.

Digital operating procedure created using TULIP

Create applications without programming

Combine with IoT devices such as indicator lights and sensors

Basic set