- Customer Case Example 2025/12/16 UP

-

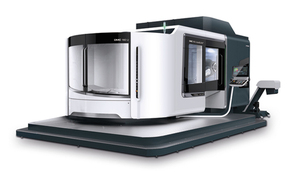

Whether in the automotive industry, agricultural machinery manufacture, aviation, or any other industrial sector, prototype production is fundamental to progress. It makes visions tangible and separates the feasible from wishful thinking. One expert in this field is ACTech GmbH, founded in 1995 in Freiberg. As a pioneer in laser sintering, a 3D printing process, the company was able to produce the molds required for prototypes faster than most of its competitors, leading to consistent growth. ACTech now uses the binder jetting process with 3D sand printing technology to produce prototypes even more efficiently and precisely. In 1999, a mechanical processing facility was set up, followed by an in-house foundry in 2001. Today, ACTech, part of the Belgian Materialise Group since 2017, supplies around 1,700 customers in 40 countries worldwide. DMG MORI has been an important supplier of machining capacity from the very beginning. A second location in 2024 gave ACTech sufficient scope to make further investments. Two DMC 160 duoBLOCK machining centers, which are automated via a linear pallet pool system (LPP 5000), four DMU 85 monoBLOCK machines, each with a PH Cell 800, and a DMU 200 Gantry with 4,000 mm travel in the X-axis have expanded to 13 the number of DMG MORI machines installed.

Using two DMC 160 duoBLOCK machines, which produce components automatically via a linear pallet pool system (LPP 5000) using pallets measuring up to 1,250 x 1,000 mm, ACTech machines complex prototypes for applications such as engine manufacture and agricultural machinery construction.

ACTech processes medium-sized workpieces on four DMU 85 monoBLOCK machines, each automated via a PH Cell 800.

From CAD model to ready-to-assemble prototype

“The high level of vertical integration gives us a great deal of flexibility, enabling us to guarantee short delivery times of three to five weeks, depending on the project,” explains Norbert Demarczyk, Managing Director of ACTech. Automotive engineering has always been of great importance to ACTech. “But product innovation cycles are also becoming shorter in other industries, which is leading to an increasing demand for prototypes.” Concrete examples are housings for the agricultural machinery industry, energy technology parts, and structural components for electric vehicles (produced by giga casting). The manufacturing process for prototypes has not changed significantly since the 1990s. ACTech uses CAD data provided by customers to produce a casting mold using 3D printing and then casts the raw parts. Precision machining is performed on modern machining centers. ACTech carries out the large amount of programming involved in prototype manufacture at 15 programming stations. “Thanks to four measuring machines and a ScanBox from Zeiss, we can perform precise, on-site checks to ensure our products meet tolerance specifications down to the micron level.”

“DMG MORI's automation solutions enable us to increase our capacity, while at the same time operating more flexibly.”

Norbert Demarczyk, Managing Director (right)

and Georg Sandig, Head of Mechanical Machining at ACTech

Increased productivity through flexible pallet handling

According to Georg Sandig, Head of Mechanical Machining, there were several reasons for modernizing production: “On one hand, we needed to increase our capacity, and on the other, we saw potential in automation solutions to become even more flexible,” he says with regard to pallet handling. The LPP 5000, for example, has space for 20 pallets and is loaded via an ergonomic setup station. “Accessibility is better than in a machine shop, and we can prepare orders while the two machines process them with minimal downtime.” Orders are managed by an in-house developed MES system that prioritizes the sequence as required. The advantages of the LPP 5000 also apply to the four PH Cell 800 machines. Each of these has space for up to 18 pallets. Norbert Demarczyk adds: “The pallet handling systems enable us to manufacture small series very efficiently.”

The right tools for every component

The components on the pallets measuring up to 1,250 x 1,000 mm in the LPP 5000 are machined by two DMC 160 duoBLOCK machines. According to Georg Sandig, a highlight are the large tool magazines with 303 stations. “This was an important criterion for us because prototypes are often machined with an enormous number of different tools.” Accordingly, the warehouse contains over 15,000 different types of tool, many of which are expensive special tools. “Probably the largest in Central Saxony,” he jokes. Transparent tool management helps to keep track of everything. “Since we don't mill from solid billets here, we can use the tools for a relatively long time with appropriate maintenance.” The large number of tools illustrates the complexity of the prototypes. “High-precision machining centers for 5-axis simultaneous machining are absolutely essential here,” emphasizes Norbert Demarczyk. “On an older DMU 160 FD duoBLOCK, we can even completely mill and turn parts economically.”

Customized machining of titanium implants

Typical materials used in prototype production are aluminum, cast iron, and various steel alloys. In addition, ACTech now also machines titanium shoulder implants. “These are powder bed-printed components that we subsequently machine,” says Georg Sandig, describing the manufacturing process. Post-processing of additively manufactured components is necessary to achieve the desired accuracy. “The combination of 3D printing and milling allows for patient-specific customization of implants – a growing trend in the medical sector.”

Planned growth

ACTech made the investment in the second location after careful planning. “We have enough space here to continue growing, for example by mirroring the LPP and doubling capacity,” says Norbert Demarczyk, referring to the available production area. Giga casting is also a topic of discussion. “The DMU 200 Gantry expands our capabilities in the machining of large underbody structures for electric vehicles.” The variety of machining options helps to open up new markets. He cites Japan and China as promising examples. In terms of industries, he sees potential in drive technology and the aviation industry, among others: “Wherever development cycles are becoming shorter, we benefit from our many years of expertise in prototype production for automotive manufacturers.”

Note: Organization names and titles are current as of publication timing.

This content is for members only