- Customer Case Example 2025/08/25 UP

-

Voigt Systemtechnik GmbH from Großbreitenbach in Thuringia was founded by brothers Jens and Eckhard Voigt in 1990 shortly after reunification. It was the continuation of a family tradition, which was started by their great-grandfather at the end of the 19th century. Following the new foundation, the range of services was quickly expanded to include industrial parts manufacture and assembly. There are now around 140 specialists working at the location. They manufacture complex and precise workpieces as well as entire assemblies for a range of sectors including medical, analytics, the optical industry, and electrotechnology. The plant list comprises approximately 40 machines, 15 of which are from DMG MORI and some of which are also automated. The latest addition is a DMU 40, which has been tried and tested by Voigt Systemtechnik as a beta test customer.

Flexible parts manufacturing for the most diverse industrial applications

Managing Director Jens Voigt knows that his experienced engineers and the versatility of the company's machine tools are the basis of Voigt Systemtechnik's sustained success: “Parts manufacturing in particular requires us to react flexibly to the different workpieces and batch sizes.” Series of up to 3,000 parts are just as likely to be on the daily schedule as medium-sized production runs. “We have also used our expertise to develop our own products, including an adaptive jet cleaner that cleans tanks on the inside highly efficiently, and a gripper for sensitive products, controlled by compressed air,” Jens Voigt says, pleased with the innovative developments.

5-axis machining with DMG MORI

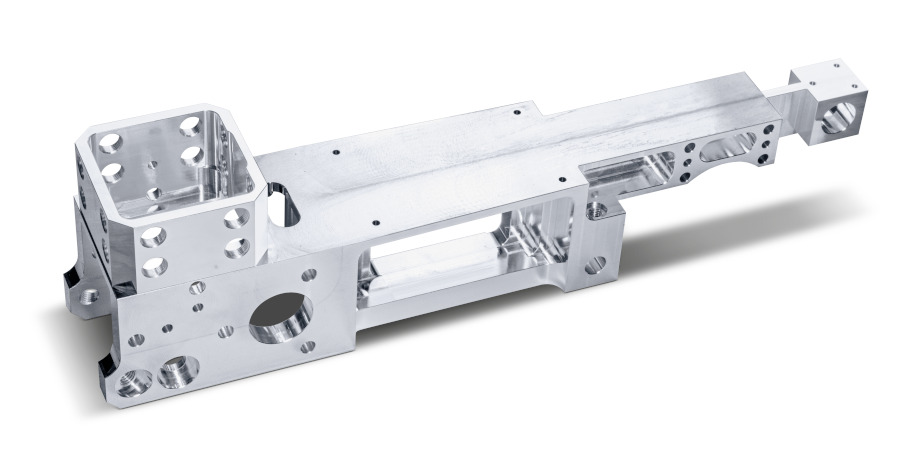

Complex components are typical of customer orders. Modern manufacturing solutions are needed to machine them, ideally 5-axis machines, which Voigt Systemtechnik has been purchasing from DMG MORI for many years. 5-axis machining centers in a wide range of sizes have long had a place in production, including a DMU 50 eVo linear, two DMU 50s, a DMU 70, a DMU 100 and a range of DMC machines. In addition there are other production centers – an NLX 2000, for example.

DMU 40 IN BETA TEST:

WORKPIECES UP TO ø 500 × 445 mm IN A FOOTPRINT OF < 5.1 m2

The importance placed on 5-axis technology and the longstanding good and cooperative relationship with DMG MORI has now led to the installation of a beta test machine tool from DMG MORI. The new DMU 40 was installed in 2022. The machine tool manufacturer designed the compact universal machine to introduce customers to 5-axis simultaneous machining based on the DMU 50 3rd Generation. Even more compact than the DMU 50 and with a machine width of just two meters, the DMU 40 offers travels of 550 × 450 × 420 mm. It enables 5-axis simultaneous machining of workpieces up to ø 500 × 445 mm and up to 300 kg. High-quality components such as the one-piece machine bed made of cast iron, the geometry-optimized Y- and Z-axis slideways, as well as the speedMASTER spindle from DMG MORI ensure complex parts can be machined precisely.

DMU 40:ENTRY-LEVEL 5-AXIS SIMULTANEOUS MACHINING

- Travel X/Y/Z: 550 / 450 / 420 mm

- Excellent stiffness due to one-piece cast iron machine bed

- High dynamics with rapid traverse up to 30 m/min

- Integrated 5-axis simultaneous table with large swivel angle (-35° / +110°)

and maximum table load of 300 kg - High accuracy due to direct drives in the X- and Y-axis

- < 5.1 m2 footprint (without chip conveyor):

One of the most compact 5-axis universal milling machines on the market

5-axis precision machining to within 5 µm tolerance

“The installed machine was designed specifically to machine aluminum and stainless steel, which makes it perfect for our manufacturing,” explains Michael Weyrauch, Process Manager at Voigt Systemtechnik responsible for the project involving the DMU 40. The speedMASTER spindle rated at 20,000 rpm was selected for this purpose. “It had already proven itself to be very reliable in other machining centers. We use it to machine complex workpieces productively as well as precisely and can even achieve accuracies of up to 5 µm under optimal conditions. We are currently running the machine in two-shift operation. However, with the appropriate automation, its high reliability and dimensional stability would also make it suitable for unmanned production during night shifts. Of course, the range of parts needs to be appropriate,” adds Michael Weyrauch.

The DMU 40 has decisively proven itself in our multi-shift operation. Its stability and precision mean we can achieve accuracies of 5 μm.

Jens Voigt

Managing Director

Voigt Systemtechnik GmbH

Automated series production for small parts

According to Jens Voigt, Voigt Systemtechnik already achieves increased productivity with automated machining centers including during unmanned night shifts: “We have been using three MILLTAP 700s and a DMP 70 for manufacturing medium and large series since 2016 – all with the WH 3 Cell workpiece handling system.” Voigt Systemtechnik considers automated manufacturing to be important for raising production output going forward: “If the range of parts is suitable for the machine, we will continue the automation process. We have already ordered a DMP 70 with WH 3 Cell.”

DMU 40 and Robo2Go Milling

When it comes to smaller batch sizes, Voigt Systemtechnik is also moving towards automation. As the next step, DMG MORI will install another DMU 40, this time with Robo2Go Milling. “This easy-to-operate robotic automation system has a workpiece magazine with a flexible grid that allows us to customize it to suit our parts.” The Robo2Go Milling has a load handling capacity of 25 or 35 kg, depending on the version.

Note: Organization names and titles are current as of publication timing.

This content is for members only