- Customer Case Example 2025/04/22 UP

-

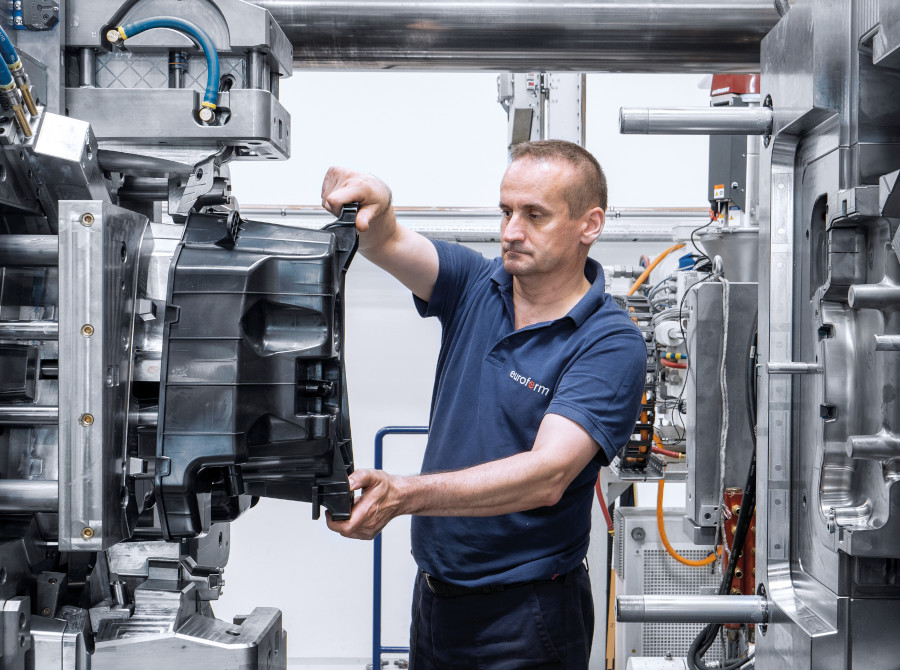

Euroform Kft. based in Budapest has been a reliable and competent partner in tool and mold making since 1993. From design to production and trialling, the approximately 70 experienced employees realize innovative solutions for a wide range of different injection molding processes. Demanding customers, mainly in the automotive industry, trust in the high quality of the products. In order to live up to this trust, Euroform uses modern and powerful machining centers from DMG MORI in tool production. The company currently uses eight models from the machine tool manufacturer, including DMU monoBLOCK machining centers, an HSC 75 linear and – the most recent investment – a DMU 100 P duoBLOCK. In addition, DMG MORI has installed the first PH Cell 2000 on the market for this machine so that Euroform can now utilize the capacity at night and during the weekends.

End-to-end competence for injection molds

With injection moulds for 2,000 automotive components, seat pans, engine covers and tanks, Euroform has made a name for itself throughout the entire sector. “As a partner for suppliers and manufacturers, our work begins in the early development phases of new vehicles,” says Stefan Wolf, the company’s managing partner, about the close cooperation with customers. Euroform meets its high quality requirements with well-trained specialists in both design and production. “Technical competence is crucial for fully exploiting the potential of both modern CAD/CAM systems and innovative manufacturing solutions.”

This content is for members only