- Customer Case Example 2025/02/28 UP

-

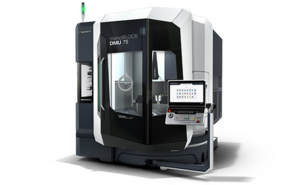

Wehl & Partner Muster + Prototypen GmbH produced the first workpieces for customers in the automotive and medical sectors as early as 1994 – at that time still in a garage and with the help of a domestic oven to harden molds. Today, the company has 80 employees at an ultra modern plant in Zimmern ob Rottweil and also operates from an additional location in Spain. There is also a subsidiary in Salach. The technological capabilities of Wehl & Partner include conventional machining, additive manufacturing and injection molding. To ensure only perfect samples and prototypes are delivered, the company relies on innovative manufacturing solutions from DMG MORI. 24 models from the machine tool manufacturer are used in production, including numerous, partly automated, 5-axis simultaneous machining centers. These include the two latest investments: Wehl & Partner has automated two DMU 75 monoBLOCKs and two DMU 50 3rd Generation machines, each via a PH Cell Twin from DMG MORI.

With the two PH Cell Twins, we were able to expand the production capacity of four machines by introducing additional unmanned shifts at night and at the weekend – without extending our factory thanks to the small 12.9 m2 footprint.

Alexander Wehl, Managing Partner

with his brother Robert Wehl, Managing Partner (right)

Wehl & Partner Muster + Prototypen GmbH

This content is for members only