- Masterpiece in the world 2025/01/14 UP

-

Masterpiece in the world #37

Automatic tool measurement with unparalleled speed and precision!"LC50-DIGILOG" laser measurement system (Blum-Novotest K.K) delivers high reliability even in extreme environments

- Tag

-

- On-machine measuring system

- Tool management

- Productivity improvement

"Internal measurement systems" are capable of automatically measuring the length and diameter of a cutting tool inside a machine, without any need to remove the tool from the machine. Such systems are already quite popular due to how they can improve productivity. However, it can take some time to complete measurements depending on the environment inside the machine, due to issues such as measurement retries and measurement errors caused by coolant.

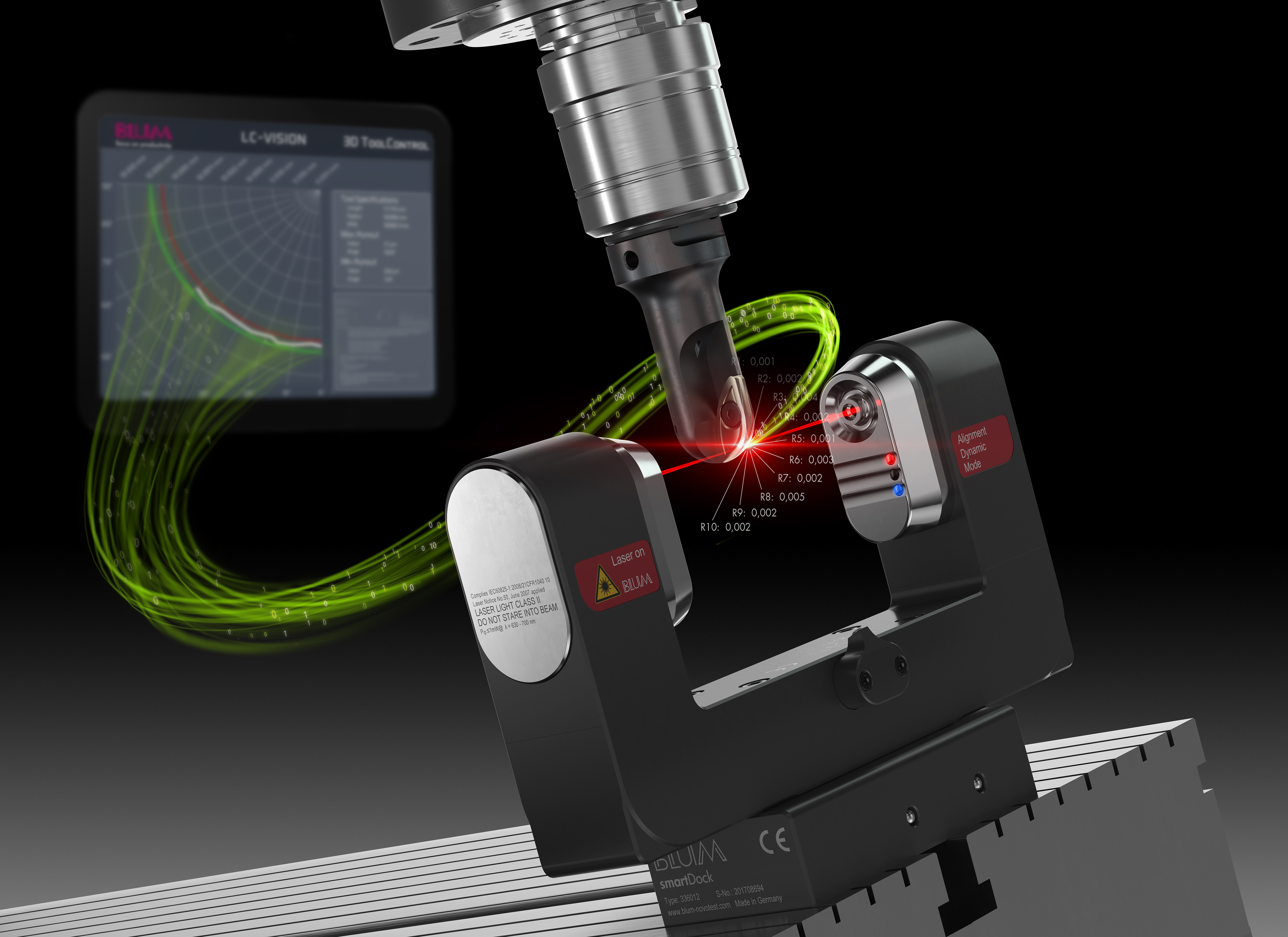

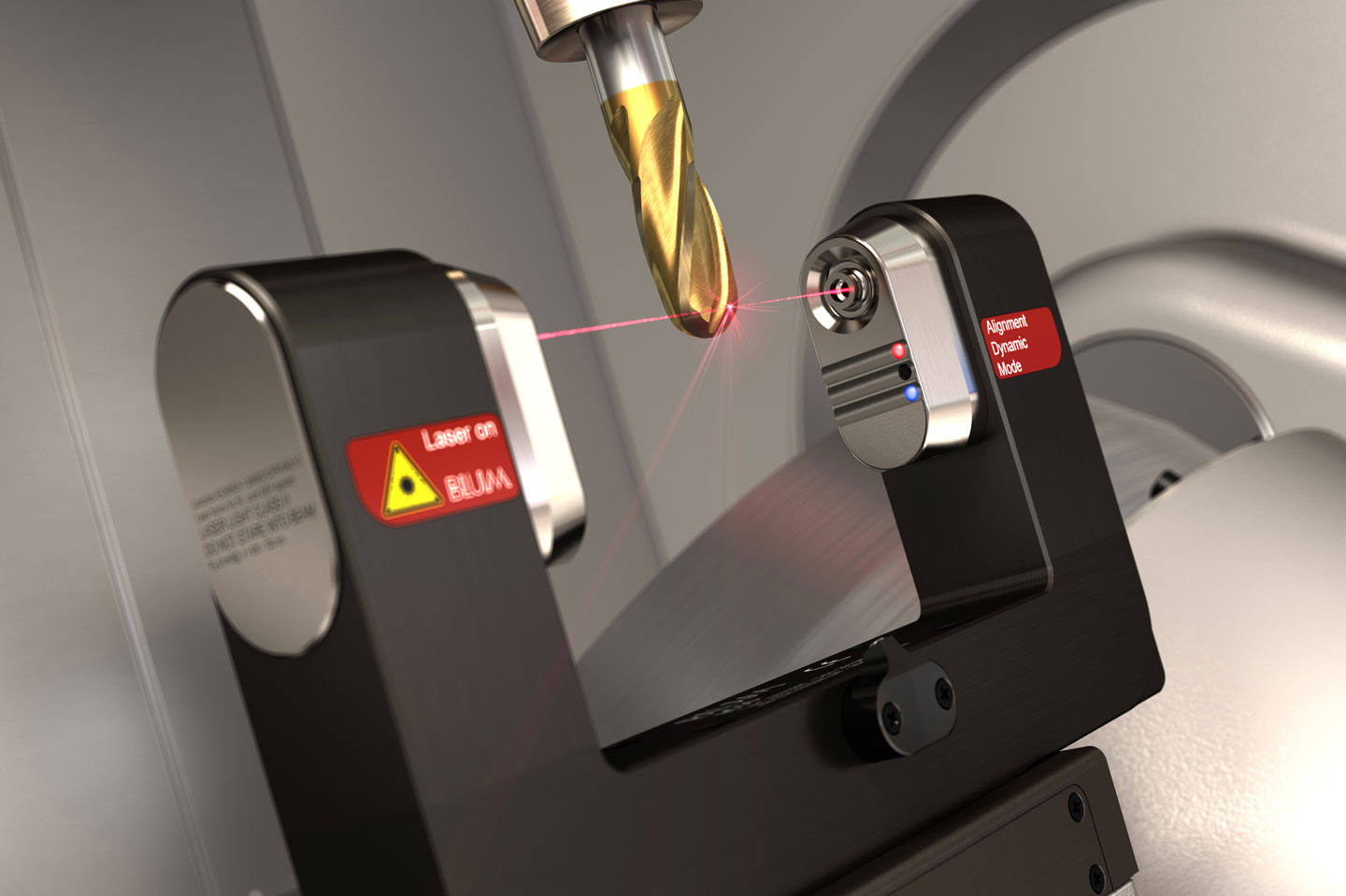

One solution to this is the "LC50-DIGILOG" tool measurement laser system from Blum-Novotest. It uses proprietary DIGILOG technology to automatically measure live tool length, diameter, runout, and more. It can do so quickly and precisely, and even under extreme internal machine conditions. In addition, wear and chipping can also be detected. No contact is made during measurement inside the machine, allowing it to measure and correct rotating tool edges down to the micrometer level, improving machining precision and maximizing production efficiency.

DIGILOG technology combines both digital and analog technologies,

and can measure and detect variation between multiple blades up to 60% faster than conventional machines, during tool measurement and detection

LC50-DIGILOG makes use of proprietary Blum-Novotest DIGILOG technology, which combines digital and analog measurement technologies. DIGILOG technology measures by conducting a high-speed scan using analog signals, and then finally outputting measurement data as digital data. This technology obtains an enormous amount of measurement data quickly, allowing for tools to be measured with even greater speed and reliability than before. For example, measurement cycles are even shorter than those of conventional laser measuring instruments, with some users reporting a reduction of up to 60% in tool measurement and detection times.

Digital signals are typically used to measure the longest and largest cutting edges when measuring multiple blades, but DIGILOG technology can be used to measure and detect variation among multiple blades. It can even determine edge chipping or wear on tools, helping prevent significant reductions in machining precision.

It is also possible to set the wear tolerance before measuring, and LC50-DIGILOG will output an alarm and replace the tool with a spare tool once finished.

Determines whether the laser is being blocked by the tool, for highly precise measurement

Optimizes and stabilizes tool measurement even when machining using coolant

In conventional laser measuring instruments, coolant obstructing the laser can result in measurement errors or retries and even cause the machine to stop. LC50-DIGILOG with DIGILOG technology is the solution to this issue with its "drop-stop functionality." LC50-DIGILOG monitors whether the laser is being blocked by the tool. If coolant blocks the laser, it determines that the laser is not being blocked by the tool. A weakness of digital signals is that they are either OFF or ON (0 or 1). In order to compensate for this weakness, the system makes use of analog signals, preventing measurement errors and retries. This allows for extremely quick and reliable measurements, even inside the machine during machining with coolant being sprayed.

LC50-DIGILOG can also be incorporated into continuous production processes using equipment such as automation systems to automatically measure tools and detect tool edge wear and chipping, for more reliable production.

Quickly and precisely measures tool length and diameter, without any impact from tool tip runout or elongation caused by thermal displacement

LC50-DIGILOG can quickly and precisely measure live tools. It is also possible to measure at machining speed during actual production. That means it can measure and correct tool length and diameter even in conditions including tool tip runout or elongation caused by thermal displacement.

LC50-DIGILOG is capable of highly reliable measurement even under extreme conditions inside the machine, and is used in all types of industries, from mold machining requiring high precision to mass production machining.

Laser focus diameter approximately 30% smaller than that of conventional systems

Reliably measures even rounded corners on machines such as ball end mills

A pioneer in the field of laser measuring instruments, Blum-Novotest continues to develop new technologies with the aim of bringing further advancements to lasers with its "Focus on Productivity." The laser used by LC50-DIGILOG has a focus diameter approximately 30% smaller than that of conventional systems. The homogeneous focus laser beam enhances quality, and is capable of obtaining the best measurement results even when measuring fine tools and very small edges.

LC50-DIGILOG makes use of a circular beam that has been optimized over conventional systems, allowing it to precisely and quickly measure even tools with rounded corners, such as the ball end mills often used with 5-axis machines.

No parallel extraction or special tools needed! The laser unit can be replaced easily for immediate recovery

LC50-DIGILOG features a rounded modern design, and is structured to minimize chip accumulation. It also comes standard equipped with a new HPC nozzle, and the check valve prevents coolant from entering. The air jets provide powerful cleaning pressure concentrated on the measurement area, quickly removing coolant and chips from the tool and allowing for high-speed measurements even under severe internal machine conditions. The system provides IP68 dust and water resistance—the highest level possible.

The shutter unit features a bayonet-type lock for even better maintainability over the previous machine model. In the event that the laser unit does fail, it can be easily replaced without the need for any special tools. Parallel extraction is performed using a standard interface called smartDock, which allows for quick recovery with no need to perform parallel extraction of the laser unit itself.

The advanced laser, DIGILOG technology, and high-quality components provide for fast, precise, and reliable automatic measurement.

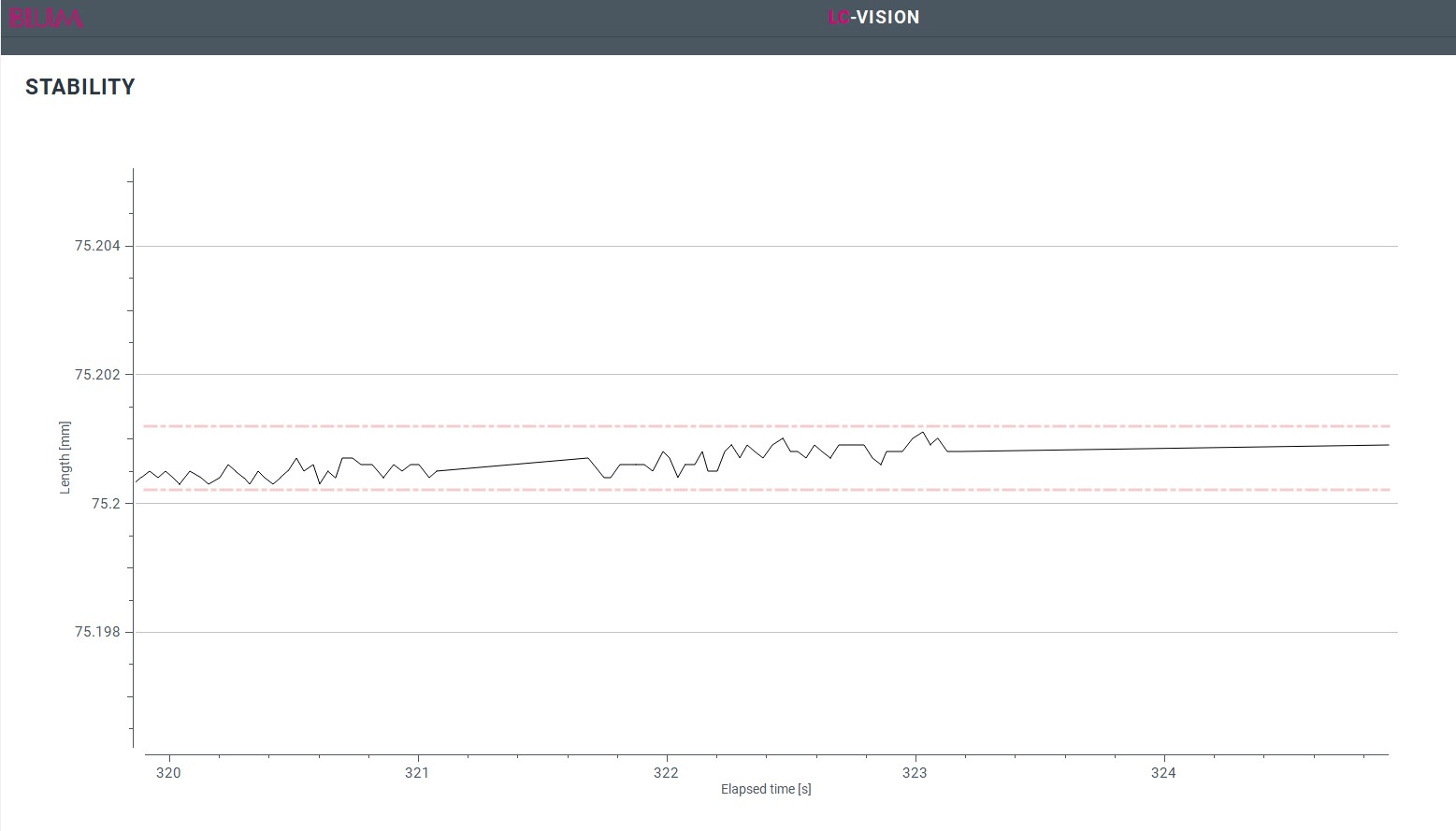

"LC-VISION" visualizes and analyzes measurement data in real time

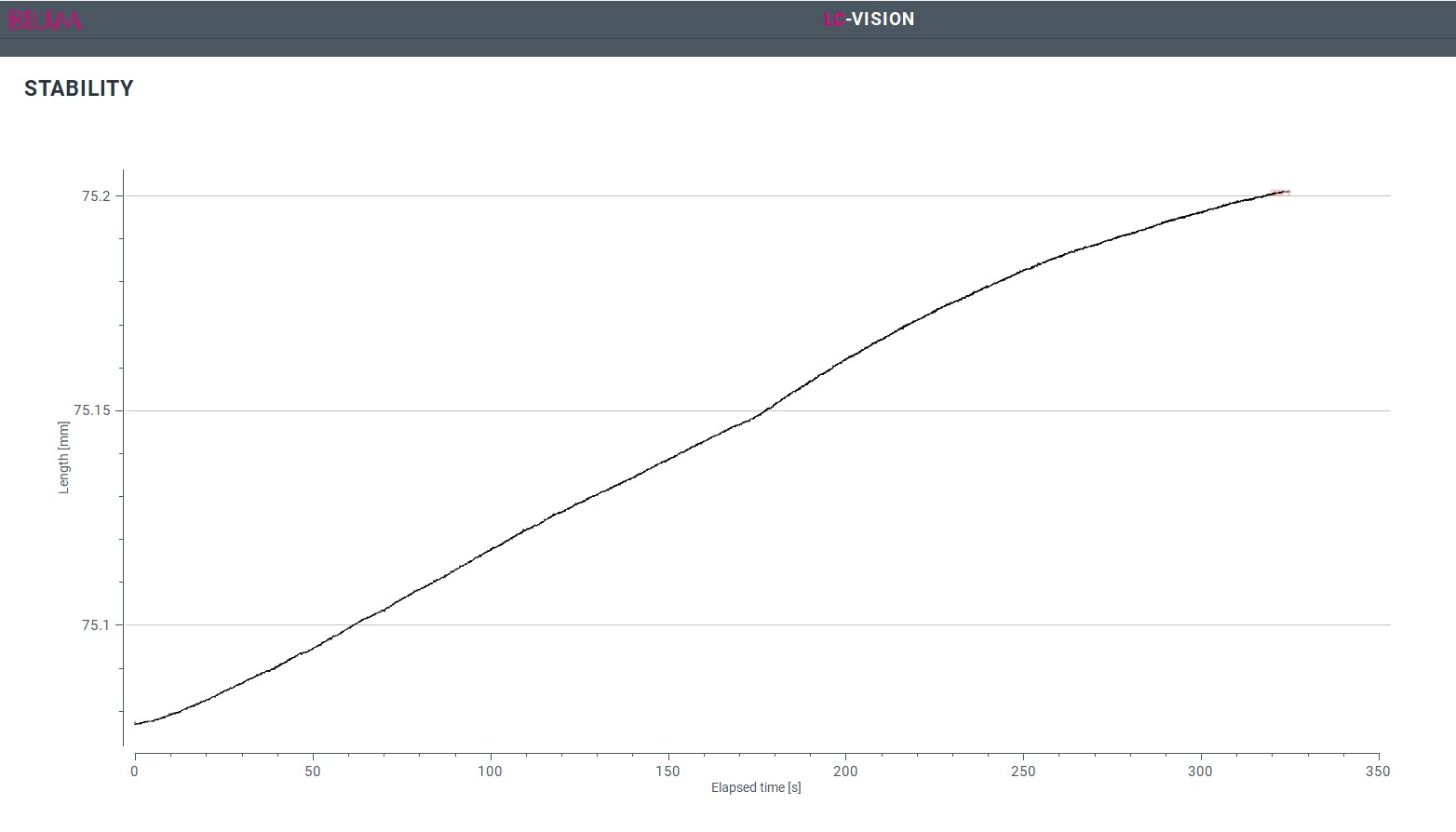

Stability Control function minimizes warm-up time

LC-VISION software can be used to visualize and analyze LC50-DIGILOG measurement data in real time.

LC-VISION comes standard equipped with the Stability Control function, which is particularly useful when starting production each day. Stability Control can be used to monitor tool tip displacement, allowing the user to confirm that machine tool thermal displacement has stabilized. It can determine when machining can start, regardless of ambient temperature or operator skill, minimizing machine warm-up time. This allows the machine to be operated longer, and also conserves energy by reducing unnecessary power consumption. It can also reduce machining variation caused by thermal displacement, resulting in machining that is stable and precise.

Moreover, LC-VISION functionality can also be expanded by adding applications. For example, "3D Tool Control" can be used to display continuous measurement data on the tool condition and to perform shape evaluation and automatic tool offset memory correction, while "Spindle Control" can be used to perform machine spindle management and minimize machining faults. New applications to meet various needs are also planned.

Total after-sales support provided by expert engineers

Blum-Novotest provides both hardware and software applications for customers in various industries, including LC50-DIGILOG and LC-VISION. Their expert engineers are highly knowledgeable and skilled, and provide extensive services covering everything from suggesting applications to providing after-sales support. With locations in 18 areas worldwide including Japan, the company is highly regarded by its many customers for the consistent service and support it provides in each country.

| Blum-Novotest K.K Address: 2202-1 Oyama, Komaki, Aichi TEL: +81 568 74-5311 |

The article introduces the DMG MORI selection of masterpiece equipment in the world.