- Customer Case Example 2025/09/22 UP

-

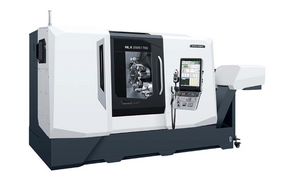

Headquartered in Katano, Osaka, Mukai Iron Works Co.,Ltd. manufactures stainless steel pipe fittings for use in semiconductors and space exploration. Its operations have been fully automated, with more than 40 machine tools operated unmanned at night. It continues to refine its expertise and pursue further automation.

Fitting parts for low-pressure pipes, machined from high-rigidity stainless steel

Trial and error to "get our machines operating longer"

Since its founding in 1961, Mukai Iron Works has developed a reputation as a specialist in stainless steel machining and is now involved in manufacturing pipe fittings and a wide variety of parts in areas such as high-mix, low-volume production semiconductors, healthcare, and space exploration. The company shifted its focus to automation in the pursuit of high-value-added manufacturing and underwent a lengthy period of trial and error. "Right around when I turned 20, I started to wonder how we could get our machines operating longer," explains Mukai Iron Works Chairman Hideyuki Mukai. The company took its first step toward automation with semi-automation, with the purchase of two turning centers in 1990.

"Our business relies on the initiative of our employees"

President Yasuhiro Mukai of Mukai Iron Works Co.,Ltd.

This content is for members only