- Customer Case Example 2025/07/15 UP

-

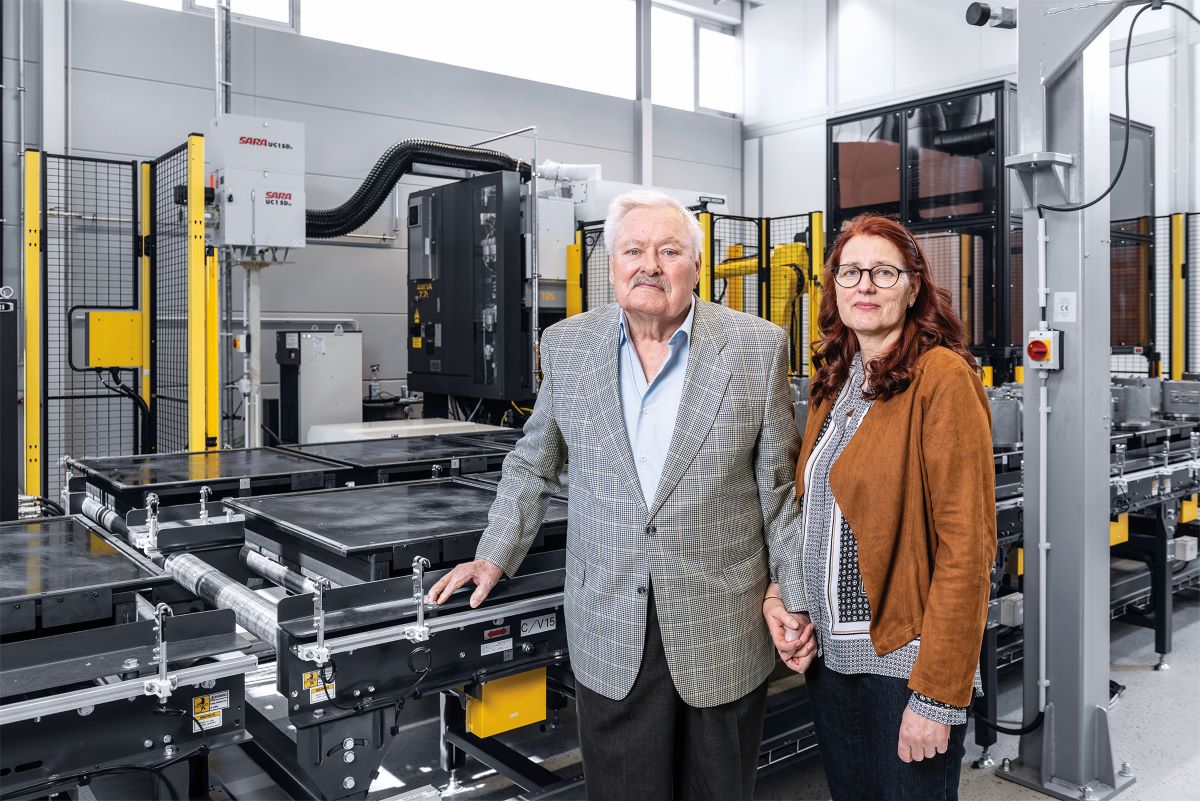

Founded 60 years ago in Groß-Zimmern, Germany, Richter Feingerätebau GmbH is an experienced supplier in the fields of hydraulics, wind power and mold making. From single parts to special solutions, 21 specialists realize highly complex components with manufacturing tolerances in the μ-range. Richter Feingerätebau has relied on CNC technology from DMG MORI for machining since 1993. Good experience with the machining centers and lathes – including a DMC 80 U duoBLOCK – led to the installation of a grinding machine from DMG MORI in 2022. The special highlight: DMG MORI fully automated the TAIYO KOKI IGV-3NT so that Richter Feingerätebau can utilize it optimally more or less around the clock.

Improved productivity with consistent quality

“As a supplier to demanding industries, we have always stood for high-quality products and absolute precision,” says Marina Gola-Richter, summing up the basic principles of Richter Feingerätebau.The second-generation family member has been managing the company founded by her father Wolfgang Richter since 2012 and knows the developments on the market very well. “Quality requirements are on the rise and components have to be available ever faster. In addition, competition is strong. In other words: in order to remain successful, Richter Feingerätebau must continuously increase its productivity – without any compromise in quality.

Thanks to the complete solution from DMG MORI, we can add two more unattended shifts to our production every day. This has been made possible by highly reliable processes and high-precision machining with accuracies of 2 µm.

Wolfgang Richter, Founder

Marina Gola-Richter, daughter and Managing Director

Richter Feingerätebau GmbH

This content is for members only