- Customer Case Example 2025/06/17 UP

-

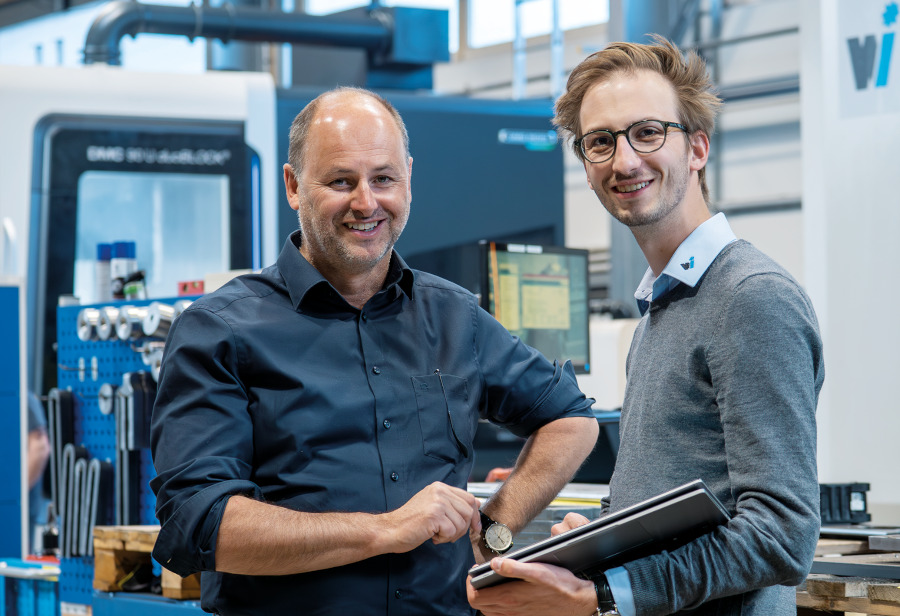

The roots of Winkelbauer GmbH from Anger in Styria date back to the 19th century – at that time it was a blacksmith’s shop for horseshoes and wagons. In 1945, the foundation was laid for today’s company. Through innovation and entrepreneurial spirit, the blacksmith's shop developed into one of the leading specialists for construction equipment and components for the recyclingindustry in Central Europe. Today, Winkelbauer has around 160 experienced engineers who manufacture high-quality tools and equipment for construction machinery up to 150 t and highly wear-resistant components for recycling plants. The traditional company ensures high product quality with a powerful and modern machine shop, including four DMG MORI machines. In addition, Winkelbauer places a strategic focus on digitization in order to optimize processes and respond better to customer requirements and changes in the market. DMG MORI's no-code platform TULIP makes an important contribution to this strategy. The APPs created with TULIP support paperless production, for example, reduce training costs and increase process reliability in assembly.

Innovative strength for generations

Winkelbauer has grown over several generations to become one of the largest sector specialists in Central Europe. "We successfully hold our own against the competition through continuous investment in the training and further education of our skilled staff and due to our competence in the processing of highly wear-resistant steel – in our case, this amounts to over 6,000 tons per year, more than 4,000 tons of which are wear-resistant Hardox steels," is how Michael Winkelbauer, Managing Director of the company founded by his grandfather, explains the company’s success. This tradition has resulted in great innovative strength, which has already generated its own patents and brands. “Moreover, in our think tank we are always looking for special solutions for exceptional challenges.”

Thanks to TULIP, we have already been able to make a large number of our processes completely paperless – from assembly and cycle time recording to quality assurance. With this digitization we have succeeded in drastically reducing the amount of training required for machine operation.

Michael Winkelbauer

Managing Director

Winkelbauer GmbH

This content is for members only