- Customer Case Example 2024/04/15 UP

-

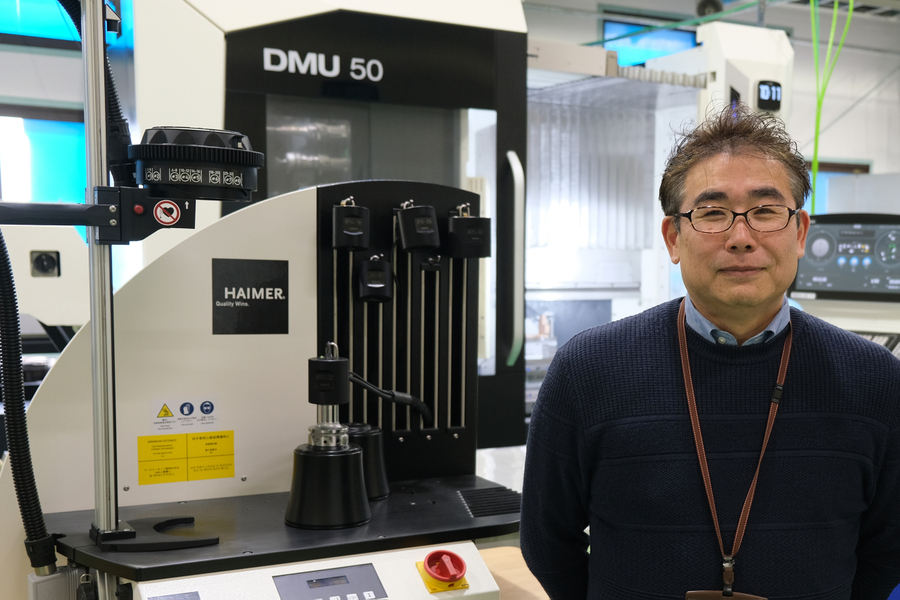

Founded in 1977, HATTORI ENGINEERING Co.Ltd. is an industrial component manufacturer operating out of Toyohashi in Aichi Prefecture. The company is involved in manufacturing motor parts for major electronics manufacturers, as well as parts for machine tools, computer equipment, medical equipment, and testing equipment. It is also involved in rivet coating. In addition to mass-produced products, the company also specializes in high-mix low-volume production tailored to customer requirements, and its track record of developing clever solutions and applying its advanced technical capabilities to design products and propose technical improvements has earned it the trust of many companies. Under its motto of "creating what customers need," the company continues to invest in its facilities, having recently installed its first 5-axis machines: DMU 50 3rd Generation.

Tools can be attached properly by anyone. Easily achieve the highest levels of machining conditions

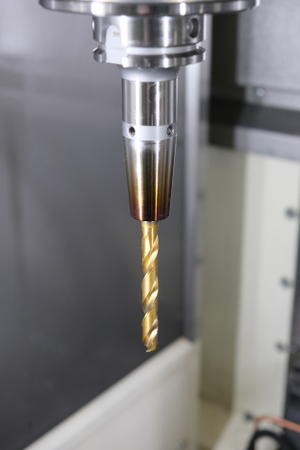

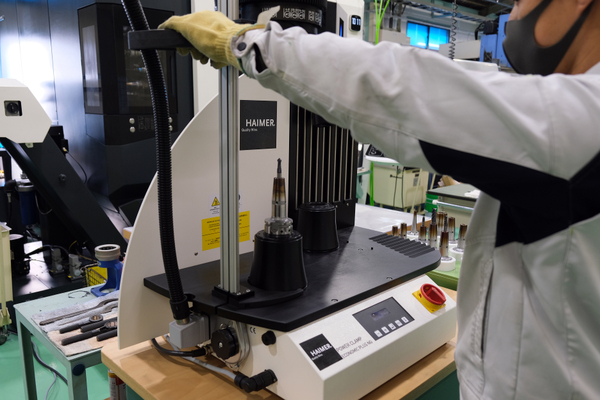

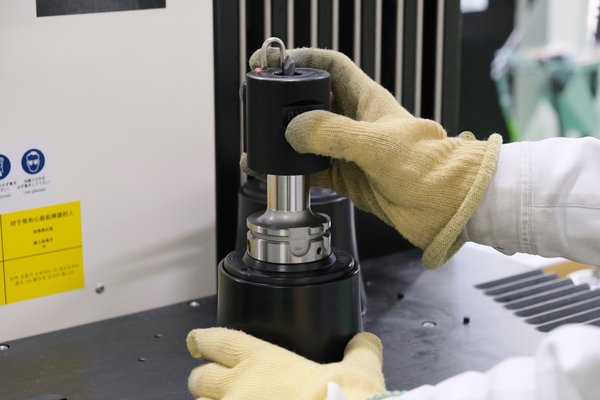

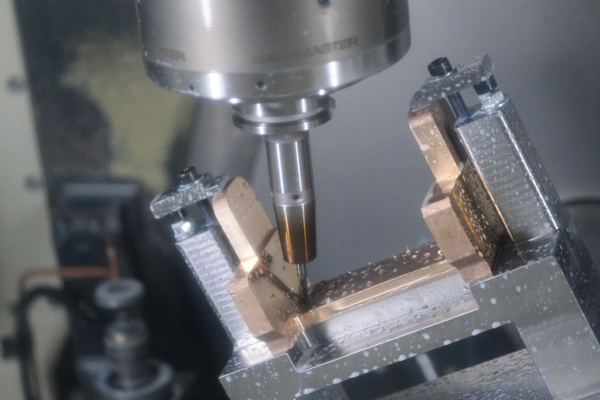

The "Power Clamp" shrink fit machine makes it possible for anyone to quickly and properly fit tools, and this has really helped us to get work done quicker. We use "Shrink Fit Chuck," a type of shrink fit holder made by HAIMER, along with DMU 50 3rd Generation to do work that's even more accurate than what we were doing with a 3-axis machining center.

HATTORI ENGINEERING Co.Ltd.

President and CEO

Yutaka Hattori

"Shrink Fit Chuck" is a shrink fit holder that is highly durable with excellent gripping force and run-out accuracy. "Power Clamp" is a shrink fit machine that makes it easy to attach and remove tools, dramatically reducing time spent on setup and the need for expert workers.

The company makes use of more than 100 HAIMER shrink fit holders with its two 5-axis machines. Power Clamp has a heating time of approximately five seconds, for quick heating and cooling.

The company uses its DMU 50 3rd Generation machines together with HEIMER "Shrink Fit Chuck" shrink fit holders and a "Power Clamp" shrink fit machine to work quickly and accurately.

This content is for members only