- Products

-

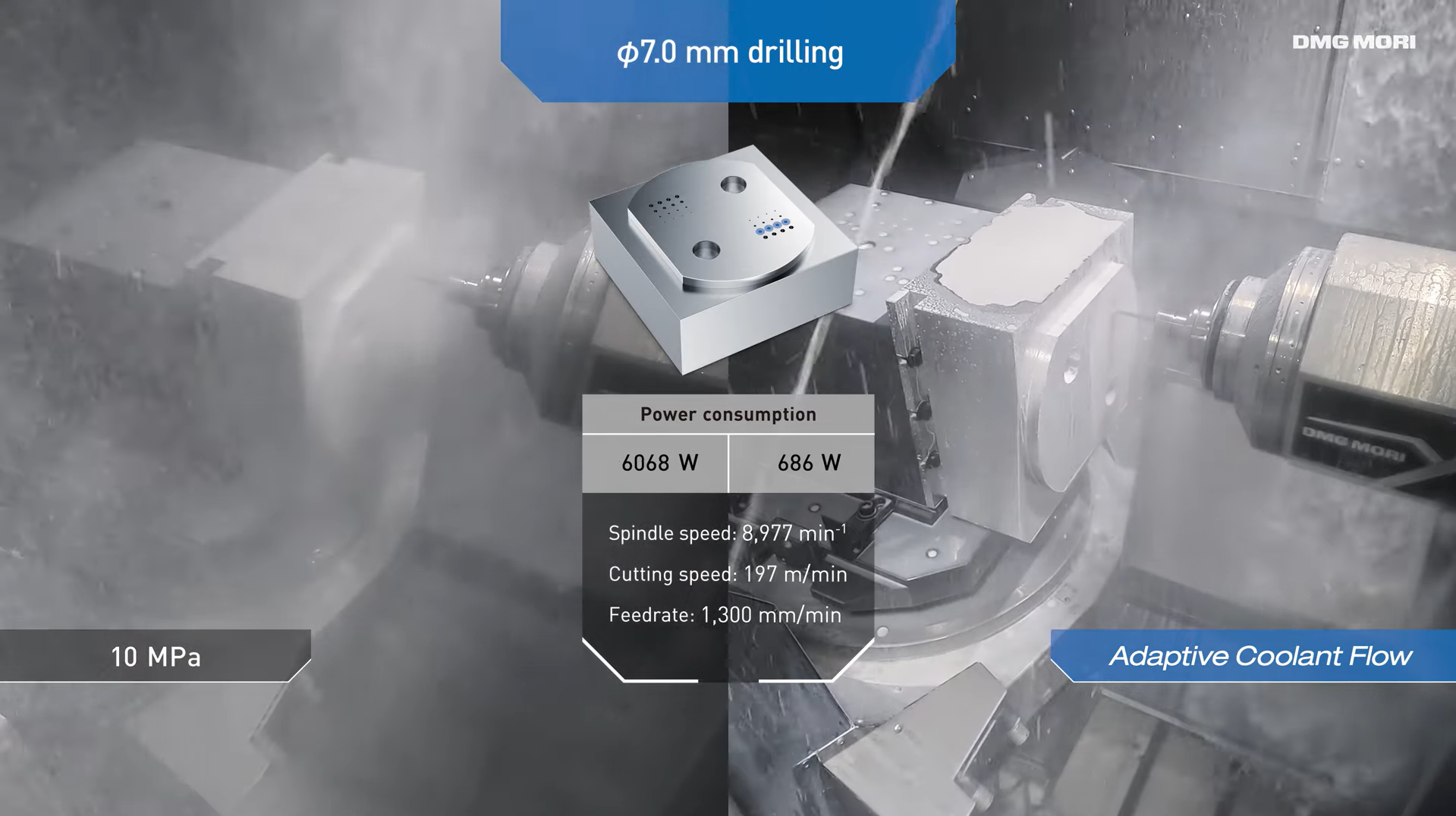

Optimizing high-pressure coolant flow for improved energy efficiency

Adaptive Coolant Flow automatically optimizes highpressure coolant flow according to the cutting tool. The system consists of two elements: software that calculates and regulates the optimal flow rate, and a control unit on the coolant tank. In comparison, Adaptive Coolant Flow reduces the energy consumption of high-pressure pumps while maintaining tool life and surface quality.

Main Applicable models

- INH series

- NHX series

- NTX series*

- NLX series*

- NZ-Platform*

*Scheduled for phased implementation starting in 2026.

Unique Selling Points

1.Capable of reducing power consumption by 80% or more*1

・Built-in sensors monitor flow rate, pressure, concentration, and temperature.

・The compact design enables efficient pressure and flow control integrated directly onto the coolant tank.

*1 Based on example data. Results may vary depending on machining conditions and external factors.

2.Simple operation

・Easy calibration on the Technology Cycle screen.

・Automatically determines and registers the coolant flow rate for each tool.

3.Green Transformation

・Adaptive Coolant Flow also minimizes mist generation and coolant evaporation in the machining area, significantly decreasing total coolant consumption.

・This results in fewer refills, higher operability, and stable automated production, particularly during unmanned nighttime and weekend operation.