5-axis control machining/process integration

As a result of advancement of machine tools, technological innovations of 5-axis control and mill-turn machines are occurring to realize highly accurate and highly efficient machining.

DMG MORI offers various peripherals and solutions as well as machine tools capable of 5-axis control and mill-turn machining.

What's 5-axis control machining / Process integration?

Advantages of 5-axis control machines

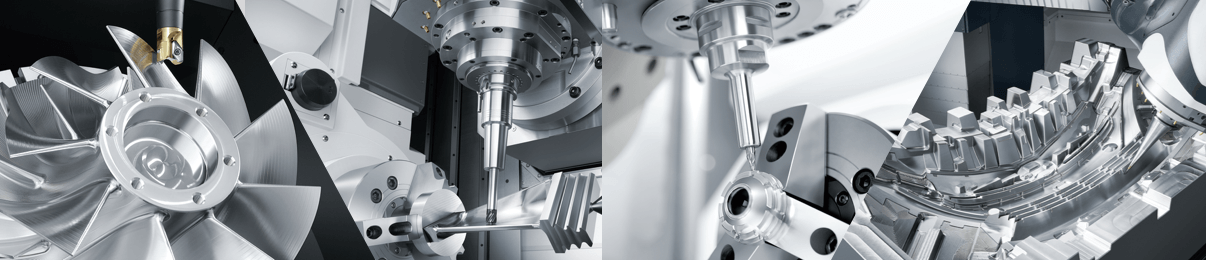

A 5-axis control machine has three linear axes (X-, Y-, and Z-axis) and two additional axes (swivel-rotary axis) to ensure a higher level of flexibility in machining.

Additional rotary axes can help reduce frequency of setup work and machining times, and increase machining accuracy and quality as multiple areas can be machined in one setup.

The machine is often considered only for special-shaped parts for aircrafts, but it actually brings more advantages than a 3-axis machine in machining of dies and molds which requires high-quality surfaces, and workpieces of general shapes.

Advantages of mill-turn machines

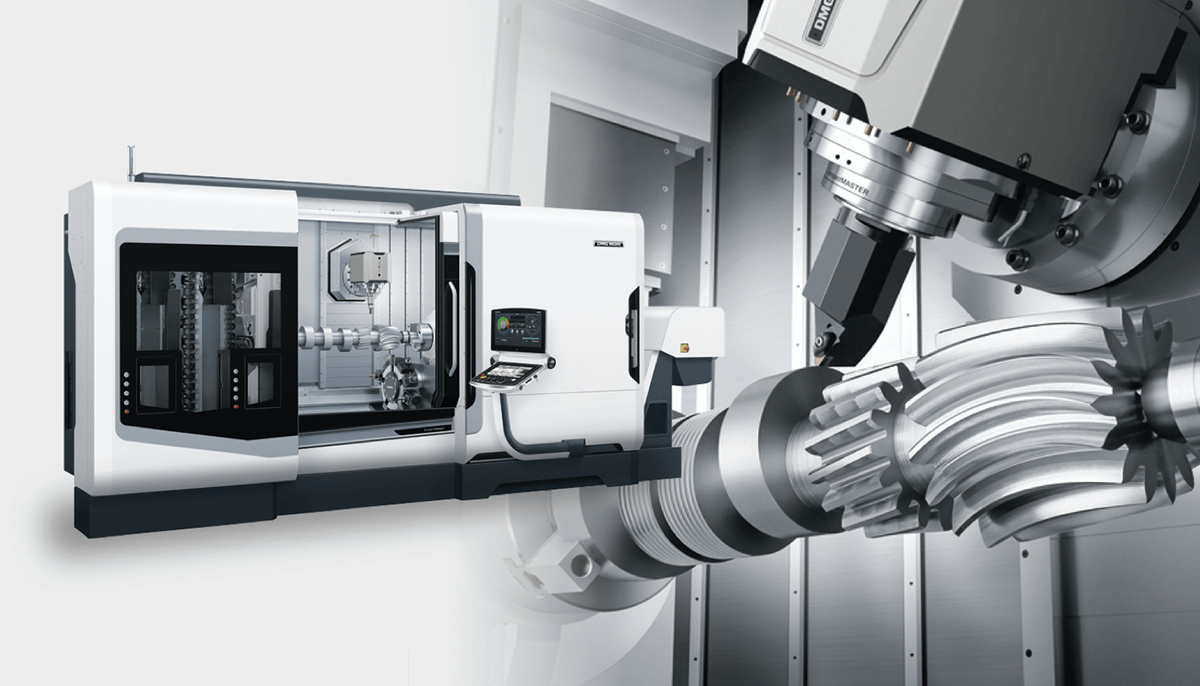

A mill-turn machine is equipped with the turning function of turning centers and milling function of machining centers to perform both types of machining operations on one machine tool.

With a combination of turning and milling capabilities, the machine is able to cut complex-shaped workpieces in the aircraft, medical equipment, automotive, die & mold and precision equipment sectors with high accuracy and efficiency. The mill-turn machine also allows process integration, space saving and even automation, achieving higher productivity.

-

Videos

2022/10/05

DMG MORI TVCM「Front Runner Vol.50 Kagara Create Ltd.」

- 473 View

- 0

-

Videos

2022/09/26

Vertical Machining center CMX 600 Vi made in India

- 264 View

- 0

-

Videos

2022/09/23

Road to Front Runner Vol.41「KIBO KOGYO Co., Ltd」 High-mix, Low-volume Processing with 5-axis Machines

- 45 View

- 0

-

Videos

2022/09/14

Road to Front Runner Vol.40「Noda Plastic Seikou Co., Ltd.」High-Precision Prototyping with 5-axis Machines

- 385 View

- 0

-

Customer Case Example

2022/09/09

Aiming to Develop Multi-Skilled Instructors:

Conducting e-learning and practical training for teaching staff- 391 View

- 1

-

Videos

2022/09/07

DMG MORI TVCM「Front Runner Vol.49 SANEI SEIKI CO., LTD.」

- 261 View

- 0

-

Videos

2022/09/05

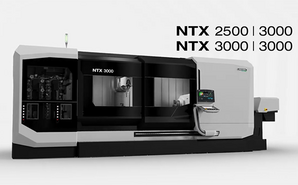

Process integration for long shaft workpieces

Integrated Mill Turn Centers "NTX 3000 / 2500 | 3000 2nd Generation"- 572 View

- 0

-

Videos

2022/09/05

Non-contact on-machine measuring system

- 444 View

- 0

-

Videos

2022/08/15

Gear Cutting with NTX 2500 and Technology Cycles

- 303 View

- 0

-

Videos

2022/08/03

DMG MORI TVCM「Front Runner Vol.48 Nabeya Bi-Tech Kaisha」

- 279 View

- 0

-

Videos

2022/07/18

Self-calibrating rotary encoder SET-HD100

- 142 View

- 0

-

Videos

2022/07/13

Road to Front Runner Vol.42「SAKATA PRECISION Co., Ltd.」 Precision 5-axis Machining for Semiconductor Manufacturing Equipment

- 496 View

- 0