- Topics 2017/02/15 UP

-

- Tag

-

- Automation

- Workpiece handling

- Pallet handling

- Loader system

- Productivity improvement

The modern manufacturing industry is faced with various big challenges to shorten lead time up to product launch in the market; ensure flexibility to handle high-mix low-volume production; and minimize costs. To achieve the goal, a whole factory needs to be streamlined, that is, a comprehensive approach is required to increase productivity. So automation is significantly important more than ever.

This article explains the merits of automation with a fundamental description in series. After the vol. 1 about “Merits of automation,” and vol. 2 about “System components,” vol. 3 explains a whole picture of automation system and the variations.

3 Types of automation systems

Automation systems vary depending on workpieces, production processes and automation methods. DMG MORI offers a wide range of automation systems, and the article explains three types of the systems and each feature. This should help you consider the installation of automation systems and make comparisons between products of different manufacturers.

| Standard Automation | Cells | Systems | |

|---|---|---|---|

| Outline |  Automation system integrated into a machine Automation system integrated into a machine |

Modularized automation system Modularized automation system |

Turnkey automation system Turnkey automation system |

| Equipment that can be used | Machine tool, modularized transfer unit (integrated into a machine tool) | Machine tool, modularized transfer unit and peripheral equipment | Machine tool, transfer unit, peripheral equipment |

| Number of machines | 1 unit | Up to 8 units | No limit |

| Production system | Cell production | Cell production | Cell production、Line production |

Standard Automation:Automation system integrated with machines

The system transfers workpieces with pallet pool systems and robots, enabling continuous machining of multiple workpieces on one machine.

As the system is a built-in type, it can achieve short delivery times, easy installation and a quick implementation of automated processes after installation. All machining processes can be completed on one machine, so it is the most reasonable and space-saving solution for customers. What’s more, some of the units can be controlled by an NC unit of a machine, so it brings benefits of easy operation and maintenance.

Automation system with Robo2Go on show at JIMTOF 2016

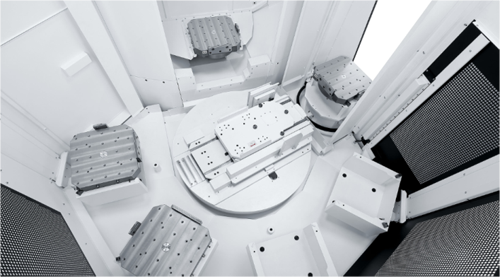

Pallet transfer module integrated into a machine tool

Cells:Modularized automation system

When a machine is purchased, necessary module(s) can be integrated into the machine to build a system.

The system employs standardized units, enabling short delivery times at reasonable prices. It also offers various combinations of modules according to customer demand. The unified operability and maintainability of the modules ensures easy operation.

DMG MORI can provide the integrated system consisting of up to eight machines and modularized units. As modularization of measuring systems, washing units, deburring units are also in progress, the integration of the post-processes will be possible in near future. The system features flexible arrangement and expansion of itself.

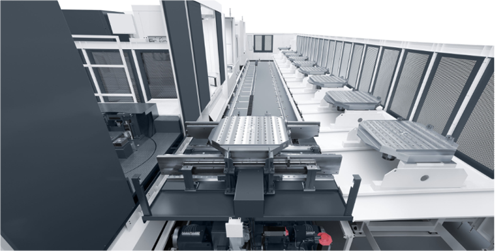

LPP (Linear Pallet Pool) system to transfer workpieces between machines

Systems:Automated turnkey production system

The biggest difference from “Cells” is that the system can be combined with non-modularized units and customer-supplied equipment (measuring systems, washing units, air blow units, leak testers, etc.) and that the number of the machines to be connected is not restricted. DMG MORI builds the systems that fully meet the customer needs from scratch and offers them as a turnkey solution.

The before-mentioned “Standard Automation” and “Cells” are mainly for cell production while “Systems” is for both cell production and line production.

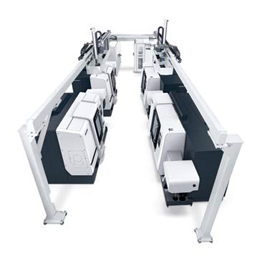

Automation system for cell production

Automation system for line production

Automation systems for cell production are built in such a way that multiple machines are arranged in a “U” shape, and that transfer systems such as gantry loaders and robots, and peripheral equipment such as measuring systems and deburring units are put between the machines. The centralized control panel for managing each machine and unit and production control system can also be integrated into the system.

With multiple cells, it’s possible to produce different workpieces in each cell. Adjustment of the number of cells and layout changes can flexibly respond to production schedule changes, enabling automation of the high-mix, low volume production.Advantages of the cell production are that automation can be implemented by cell, and that even when a machine in one cell stops, it doesn’t affect a whole production like line production as each cell is independent. Until the suspended cell makes a recovery, other cells can continue the operation.

As for automation systems for line production, on the other hand, machines for different processes are lined up with transfer systems arranged in between, and the system automatically mass-produces the same product.

Because the scale of one system is large and the installation includes a host computer as well as various machines and equipment, the system requires more cost and time in the beginning. But once it starts operation, the system delivers overwhelmingly higher productivity than the systems for cell production.

Each of the three types of automation systems has its own features and field of expertise, so please consult with DMG MORI for your best choice. As the “single-source turnkey provider,” a rare presence in the industry, we provide one-stop system solutions that integrate machine tools, transfer systems, peripheral equipment, production management systems, and even machining technologies, fixtures & tools and measurement systems.

We are also happy to provide support for system installation and troubleshooting after operation starts.

DMG MORI is determined to offer the automation system that is best suited to you.