- Tips on machining 2018/02/23 UP

-

Tips on machining vol.16

Machining a heat-treated part in one chucking

ーHard turning and hard skivingー

- Tag

-

- Turning

- skiving

- Long workpieces

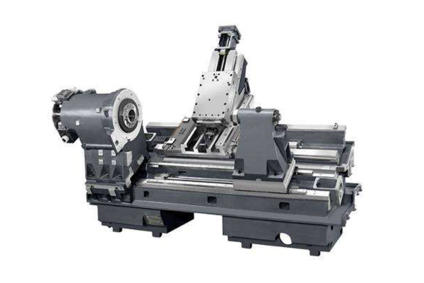

A shaft, one of the power transmission parts, is in general machined on a turning center due to its long structure. For automotive shafts, heat treatment is often performed on the entire or part of their outer diameters to ensure safety and functionality, and for portions requiring high machining accuracy such as mating parts of bearings, grinding is also performed.

To machine a long workpiece that has one or more hardened (heat-treated) portions, it is required to use a cylindrical grinding machine in addition to an NC lathe. This necessitates separation of machining process, consequently leading to decrease in productivity. In this article, we introduce hard skiving as an effective solution for this issue.

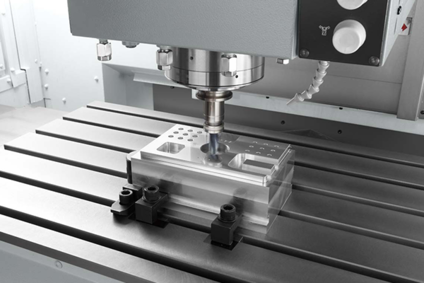

There are two ways to machine a heat-treated part in one chucking on a turning center: one is hard turning and the other is hard skiving, both of which use a CBN tip.

This content is for members only