- Tips on machining 2017/12/08 UP

-

- Tag

-

- Turning Centers

- Turning

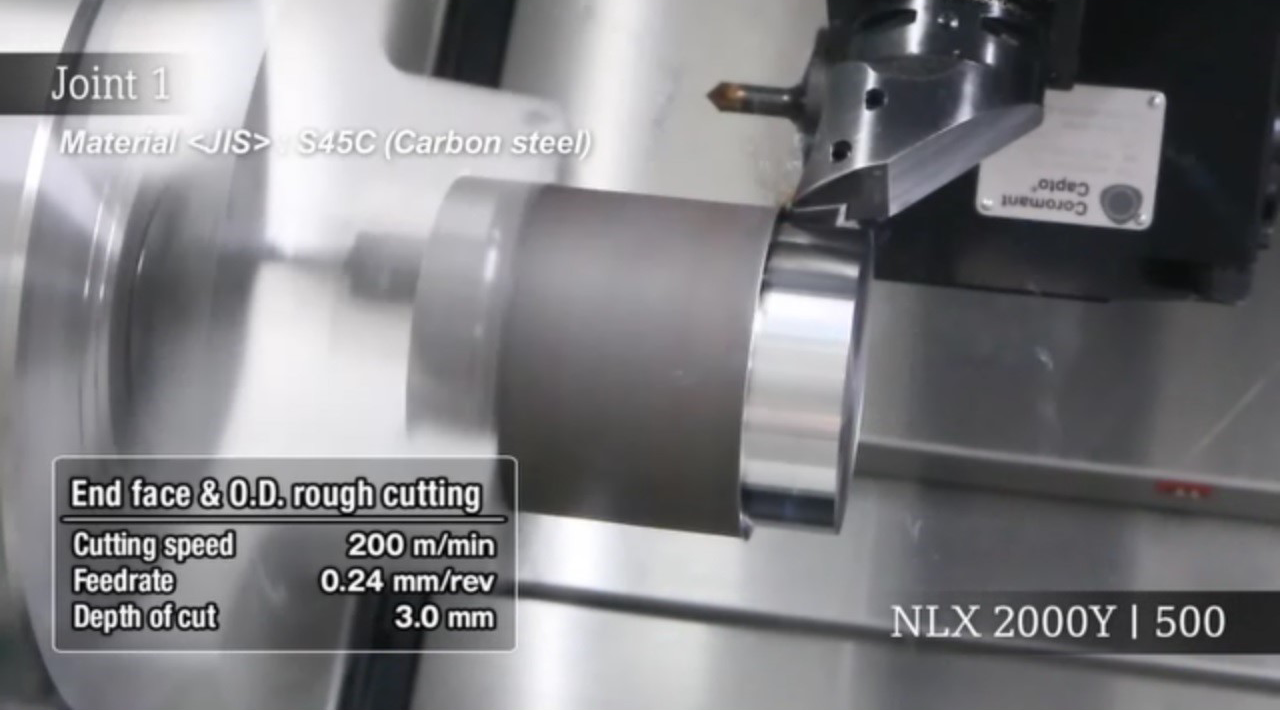

Previously, when machining was performed on a turret-type turning center, a right-hand cutting tool was attached to the machine with its rake face facing down, and the workpiece (spindle) was rotated in the normal direction. The reason for doing so was that the face-down rake face allows cutting chips to fall by gravity, which makes chip disposal easy. However, machining trends have changed over the years; faster machining is demanded for the sake of greater productivity, and chip discharge speed has also increased in line with that. As a result, a problem that flying chips can damage the internal sheet metal parts has emerged.

Machining with a right-hand cutting tool

Then, a new machining method, in which a left-hand cutting tool is attached to a machine with its rake face facing up and the workpiece is rotated in the reverse direction, has been widely used in recent years. The reason for doing so is that the face-up rake face allows chips to scatter upward into the air to prevent damage to the internal sheet metals and makes insert changes and tool tip (cutting phenomenon) checks easier.

Machining with a left-hand cutting tool

The rotation direction of a workpiece mounted on a turning center has changed from normal to reverse in the historical context as mentioned above. Today, one of the most effective machining techniques is to change the spindle rotation direction according to the purpose of machining.

This content is for members only