- Tips on machining 2017/10/12 UP

-

Tips on machining vol.13

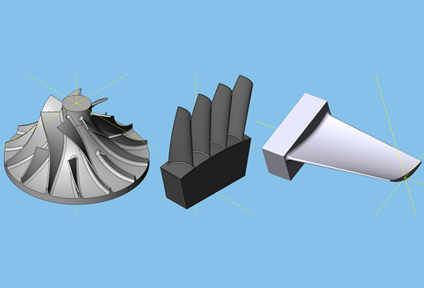

How to achieve both high-efficiency machining of general materials and machining of difficult-to-cut materials

- Tag

-

- Coolant

- Machining of difficult-to-cut materials

- Heat-resistant alloy

- Titanium

- Inconel

Why is a heat-resistant alloy difficult to cut?

Recently, efforts to reduce CO2 emissions have been accelerating towards global warming mitigation. In the automotive industry, heat-registrant alloys such as Inconel and titanium alloys have been increasingly used for engines and valves of automobiles (including trucks and other commercial vehicles). These materials have advantages of low thermal conductivity and high heat resistance, but these advantages can also become disadvantages. Cutting heat generated during machining is not conducted to the workpiece or chips but accumulates on the tool tip, causing an increase in tool tip temperature, which leads to shorter tool life. Moreover, cutting temperature increases as cutting speed increases, making it difficult for operators to increase cutting speed. This is the reason why materials like Inconel and titanium alloys are called “difficult-to-cut materials.”

Points to increase machining efficiency

This content is for members only