- Tips on machining 2017/09/11 UP

-

- Tag

-

- 5-axis control machining/process integration

- Tool

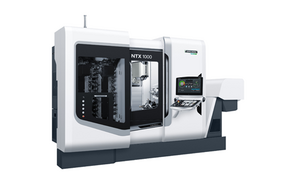

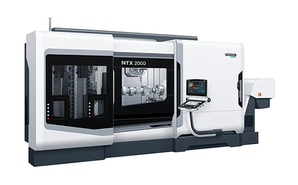

With the demand for mill-turn machines capable of both milling and turning on one machine growing, multi tools attract attentions. A multi tool, also called a combination tool or double tool, can handle multiple machining operations by itself to streamline machining processes. Despite the increasing attention on multi tools, little is known about their details. In this article, we will explain the types and merits/demerits of the multi tool, and provide practical hints for its use.

The multi tool can be roughly divided into two types: one is a “tool capable of handling multiple machining operations with a single tool path” and the other is a “tool that can complete machining of a desired shape when combined with the spindle rotation or indexing function of a machine tool.”

Fig. 1 Step and chamfer drill

Fig. 2 Multi tool made by ISCAR

This content is for members only