- Customer Case Example 2025/09/15 UP

-

In 2016, ROC Fertigung24 GmbH from Freudenstadt launched its production of high-quality forged wheels in a unique design. Automobile manufacturers, customisers and tuners enhance their vehicles with the products made by the 28-member team. Attention to detail and professional competence flow into the manufacture of the wheels – from production through to finishing. In order to meet the high demand, ROC has continuously expanded both its factory area – it all started in a garage – and its manufacturing capacity. Just shortly after the foundation of the company, a decision was taken in favor of 5-axis simultaneous machining centers from the DMU monoBLOCK series as far as milling is concerned. Today there are 14 on the shop floor, which are used to full capacity around the clock in 3-shift operation. As a beta test customer, ROC put five DMU 75 monoBLOCK 2nd Generation machines through their paces in 2022.

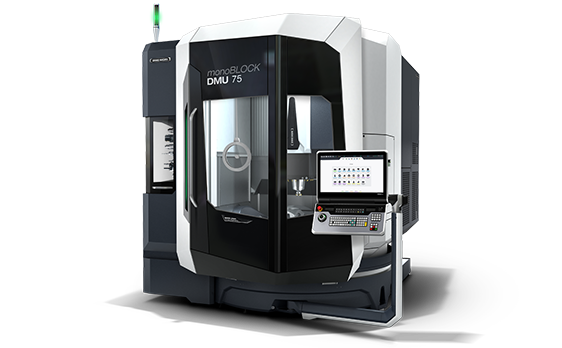

DMU 75 monoBLOCK 2nd Generation

- Easy accessibility to the working area –

both stand-alone and automated! - High rigidity thanks to the monoBLOCK made of gray cast iron and a holistic cooling concept

- 5-in-1 Technology Integration:

Milling, turning, grinding, gear cutting and measuring - Preparation for automation as standard,

ideal for retrofitting - CELOS with SIEMENS or HEIDENHAIN

This content is for members only