CNC machine tools

DMG MORI provides cutting-edge machine tools that meet the diverse needs of a wide range of industries including automotive, die and mold, aerospace, semiconductor and medical sectors.

| CMX V | Table working surface [mm] | X / Y / Z-axis travel [mm] | Tool shank type | Max. spindle speed [min⁻¹] | Machine size (width × depth × height) [mm] | ||

|---|---|---|---|---|---|---|---|

|

CMX 600 V | Videos Product page | 900 × 560 | 600 / 560 / 510 | BT40 / CAT40 / DIN40 / HSK-A63 | 12,000 / 15,000 / 20,000 / 30,000 | 2,150 × 2,752 × 2,937 |

|

CMX 800 V | Videos Product page | 1,100 × 560 | 800 / 560 / 510 | BT40 / CAT40 / DIN40 / HSK-A63 | 12,000 / 15,000 / 20,000 / 30,000 | 2,559 × 2,752 × 2,937 |

|

CMX 1100 V | Videos Product page | 1,400 × 560 | 1,100 / 560 / 510 | BT40 / CAT40 / DIN40 / HSK-A63 | 12,000 / 15,000 / 20,000 / 30,000 | 3,190 × 2,752 × 2,937 |

| NVX | Table working surface [mm] | X / Y / Z-axis travel [mm] | Tool shank type | Max. spindle speed [min⁻¹] | Machine size (width × depth × height) [mm] | ||

|---|---|---|---|---|---|---|---|

|

NVX 5060 2nd Generation | Videos Product page | 900 × 600 | 600 / 530 / 510 | No. 40 Taper: BT40 / CAT40 / DIN40 / HSK-A63 No. 50 Taper: BT50 / CAT50 / DIN50 / HSK-A100 | No. 40 Taper: 15,000(Standard specification) 12,000 / 20,000 / 30,000*¹ No. 50 Taper: 12,000(Standard specification) 12,000 / 16,000*¹ | No. 40 Taper: 2,337 × 2,971 × 2,601 No. 50 Taper: 3,168 × 2,971 × 2,601 |

|

NVX 5080 2nd Generation | Videos Product page | 1,100 × 600 | 800 / 530 / 510 | No. 40 Taper: BT40 / CAT40 / DIN40 / HSK-A63 No. 50 Taper: BT50 / CAT50 / DIN50 / HSK-A100 | No. 40 Taper: 15,000(Standard specification) 12,000 / 20,000 / 30,000*¹ No. 50 Taper: 12,000(Standard specification) 12,000 / 16,000*¹ | No. 40 Taper: 2,460 × 2,971 × 2,601 No. 50 Taper: 3,291 × 2,971 × 2,601 |

|

NVX 5100 2nd Generation | Videos Product page | 1,350 × 600 | 1,050 / 530 / 510 | No. 40 Taper: BT40 / CAT40 / DIN40 / HSK-A63 No. 50 Taper: BT50 / CAT50 / DIN50 / HSK-A100 | No. 40 Taper: 15,000(Standard specification) 12,000 / 20,000 / 30,000*¹ No. 50 Taper: 12,000(Standard specification) 12,000 / 16,000*¹ | No. 40 Taper: 3,018 × 2,971 × 2,601 No. 50 Taper: 3,604 × 2,971 × 2,601 |

|

NVX 7000 | Videos Product page | 1,700 × 760 | 1,540 / 760 / 660 | No. 40 Taper:BT40 / CAT40 / DIN40 / HSK-A63No. 50 Taper:BT50 / CAT50 / DIN50 / HSK-A100 | No. 40 Taper:14,000(Standard specification)20,000*¹No. 50 Taper:10,000(Standard specification)6,000 / 15,000*¹ | No. 40 Taper:4,280 × 3,644 × 3,167No. 50 Taper:4,280×3,644 × 3,167 |

| DMP | Table working surface [mm] | X / Y / Z-axis travel [mm] | Tool shank type | Max. spindle speed [min⁻¹] | Machine size (width × depth × height) [mm] | ||

|---|---|---|---|---|---|---|---|

|

DMP 70 | Videos Product page | 3-axis specification: 840 × 420(Fixed table) 5-axis specification: ø 290(NC swiveling rotary table) | 700 / 420 / 380 | BT 30 / BBT30 / SK30 / SK30 BIG+ / HSK-A40 | 10,000 24,000*¹ | 1,730 × 2,450 × 2,670 |

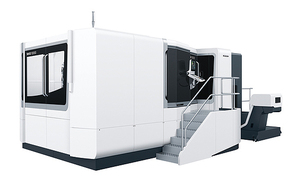

Horizontal Machining Center

| NHX | Max. workpiece size [mm] | X / Y / Z-axis travel [mm] | Tool shank type | Max. spindle speed [min⁻¹] | Machine size (width × depth × height) [mm] | ||

|---|---|---|---|---|---|---|---|

|

NHX 4000 4th Generation | Videos Product page | ø 630 × 900 | 560 / 560 / 660 | FANUC: BT40(Two-face contact) / BT40 / CAT40 / DIN40 / HSK-A63 SIEMENS: HSK-A63 / SK40(Two-face contact) | 20,000(Standard specification) 15,000 / 30,000*¹ | FANUC: 2,680 × 4,183 × 2,538 SIEMENS: 2,725 × 4,183 × 2,592 |

|

NHX 5000 4th Generation | Videos Product page | ø 800 × 1,000 | 730 / 730 / 880 | FANUC: BT40(Two-face contact) / BT40 / CAT40 / DIN40 / HSK-A63 SIEMENS: HSK-A63 / SK40(Two-face contact) | 20,000(Standard specification) 15,000 / 30,000*¹ | FANUC: 3,078 × 4,784 × 2,858 SIEMENS: 3,123 × 4,784 × 2,906 |

|

NHX 5500 2nd Generation | Videos Product page | ø 800 × 1,100 | 800 / 800 / 880 | BT50 / CAT50 / DIN50 / HSK-A100 | 12,000(Standard specification) 16,000*¹ | FANUC: 3,365 × 5,465 × 3,200 SIEMENS: 3,748 × 5,465 × 3,200 |

|

NHX 6300 2nd Generation | Videos Product page | ø 1,050 × 1,300 | 1,050 / 900 /1,030 | BT50 / CAT50 / DIN50 / HSK-A100 | 12,000(Standard specification) 8,000 / 16,000*¹ | FANUC: 3,930 × 5,917× 3,300 SIEMENS: 4,028 × 5,917 × 3,260 |

|

NHX 8000 | Videos Product page | ø 1,450 × 1,450 | 1,400 / 1,200 / 1,350 | BT50 / CAT50 / DIN50 / HSK-A100 | 12,000(Standard specification) 8,000 / 16,000*¹ | 3,994 × 7,088 × 3,674 |

|

NHX 10000 | Videos Product page | ø 2,000 × 1,600 | 1,700 / 1,400 / 1,510 | BT50 / CAT50 / DIN50 / HSK-A100 | 12,000(Standard specification) 8,000 / 16,000*¹ | NHX 10000: 5,553 × 9,111 × 3,940 NHX 10000 μPrecision: 5,743 × 9,111 × 3,940 |

| KBT-11 | Max. workpiece size [mm] | X / Y / Z-axis travel [mm] | W-axis travel [mm] | Tool shank type | Machine size (width × depth × height) [mm] | ||

|---|---|---|---|---|---|---|---|

|

PBT 110 | 1750 | Videos Product page | ø 2,400 × 2,400 × 1,900 | 2,500 / 1,800 / 1,200 | 500 | MAS BT50 | 7,500 × 7,500 × 4,600 |

|

PBT 110 | Videos Product page | PBT 110 | 1400:ø 2,000 × 2,000 × 1,600 PBT 110 | 1600:ø 2,200 × 2,200 × 1,600 |

PBT 110 | 1400:1,700 / 1,500 / 1,150 PBT 110 | 1600:2,000 / 1,500 / 1,450 |

500 | MAS BT50 | PBT 110 | 1400:6,065 × 8,000 × 3,950 PBT 110 | 1600:6,475 × 8,450 × 3,950 |

| KBT-13 | Max. workpiece size [mm] | X / Y / Z-axis travel [mm] | W-axis travel [mm] | Tool shank type | Machine size (width × depth × height) [mm] | ||

|---|---|---|---|---|---|---|---|

|

PBT 130 | Videos Product page | ø 2,650 × 2,500 × 2,100 | 3,000 / 2,000 / 1,300 | 800 | MAS BT50 | 8,400 × 7,200 × 5,050 |

*¹ option