- Products 2024/11/05 UP

-

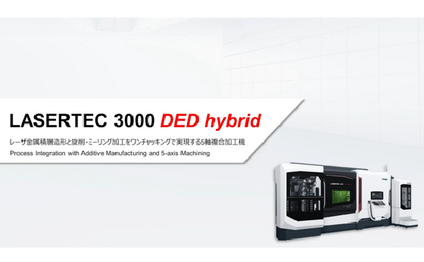

Additive Manufacturing, Turning and Milling in 1 chucking

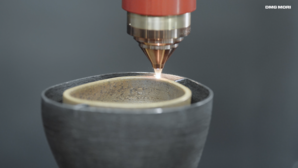

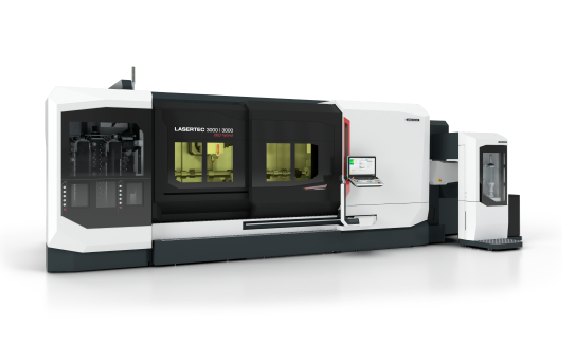

LASERTEC 3000 | 3000 DED hybrid 2nd Generation combines turn-mill and AM technology to enable conventional metal cutting and DED applications on just one machine. DED describes the process of applying metal powder through the powder nozzle in parallel to laser irradiation, in order to melt the metal powder and harden it again for deposition. LASERTEC 3000 | 3000 DED hybrid 2nd Generation offers fast deposition on large-size workpieces up to φ400 mm×2,821 mm(B axis = 90°).

The powder feeder can switch between different types of metal powder, thus allowing the deposition of multiple powders in layers on one base material. Furthermore, different types of metal powder can be already mixed before application, in order to create composite materials and realize a diverse range of depositions, repair and coating processes.