- Peripherals 2025/10/08 UP

-

Automatic cleaning hinged conveyors with filtration, capable of easily transferring even mixed chips

Turbo MH Series chip conveyors provide filtration with a built-in filter box. They make use of a proprietary LNS hinged belt to ensure that even mixed chips released by a multi-axis turning center can be transferred reliably. They provide automatic cleaning and functionality to prevent chip accumulation to reduce chip clogging, allowing for long-term continuous operation. They also keep coolant clean to help prevent tool wear and coolant degradation, reducing running costs and helping to achieve SDGs by reducing your environmental burden.

*Please contact our sales team for details.

**Manufacturer: LNS Co., Ltd (Japan)

Features

1. Hinged belt for mixed chips

Makes use of a proprietary LNS hybrid hinged belt to transfer mixed chips of various sizes and shapes, from curled chips to thin and narrow chips.

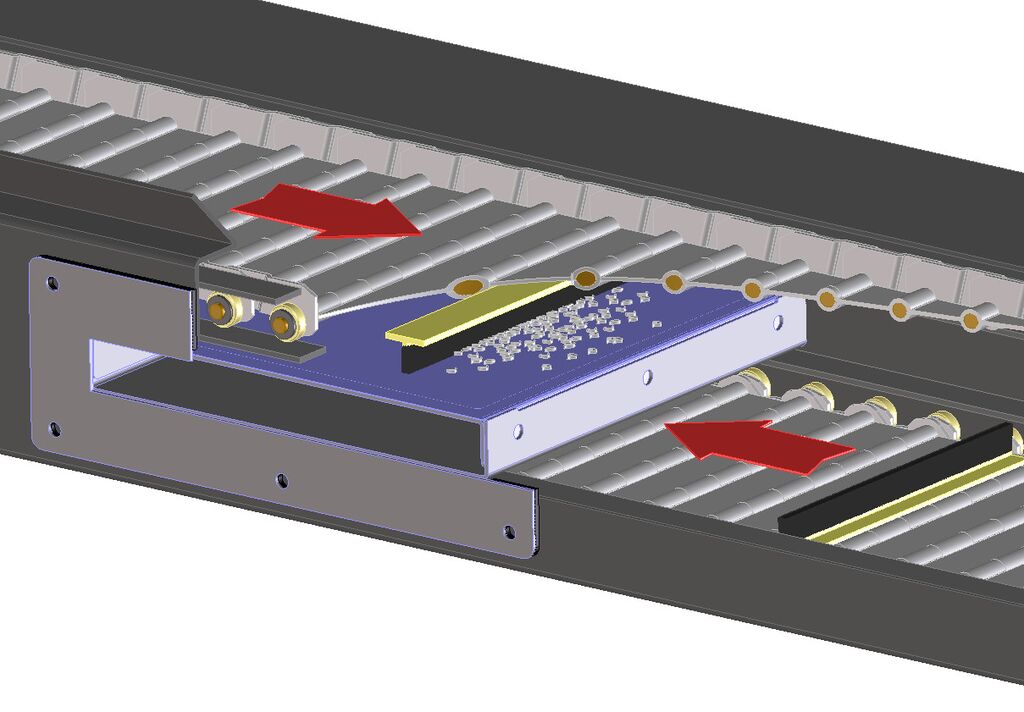

2. Filtration at a compact size

The same size as a standard hinged conveyor, and capable of processing coolant with accurate filtering (140 μ/500 μm). The filter box can be swapped in and out based on the coolant processing specifications, for flexible operation.

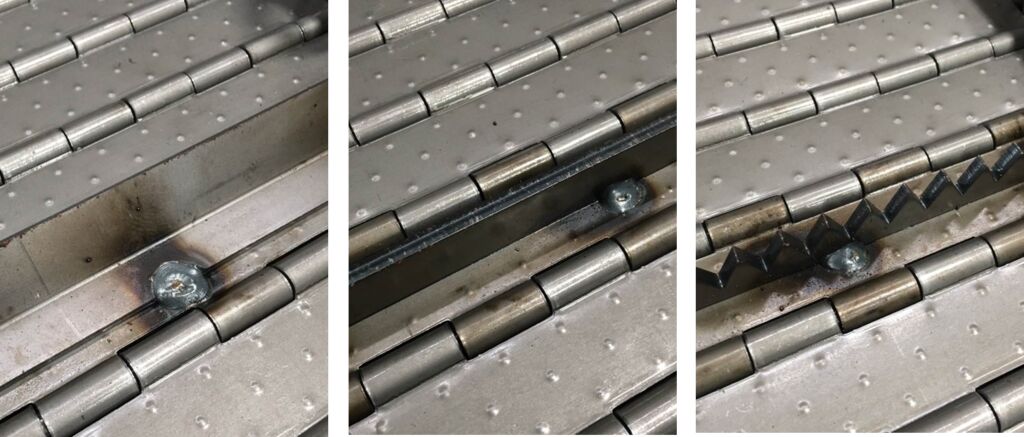

3. Simple automatic cleaning

Brushes attached on the underside of the belt automatically clean chips attached to the surface of the filter box. Brush conditions can be confirmed through the inspection window near the discharge area, allowing for the brushes to be easily replaced.

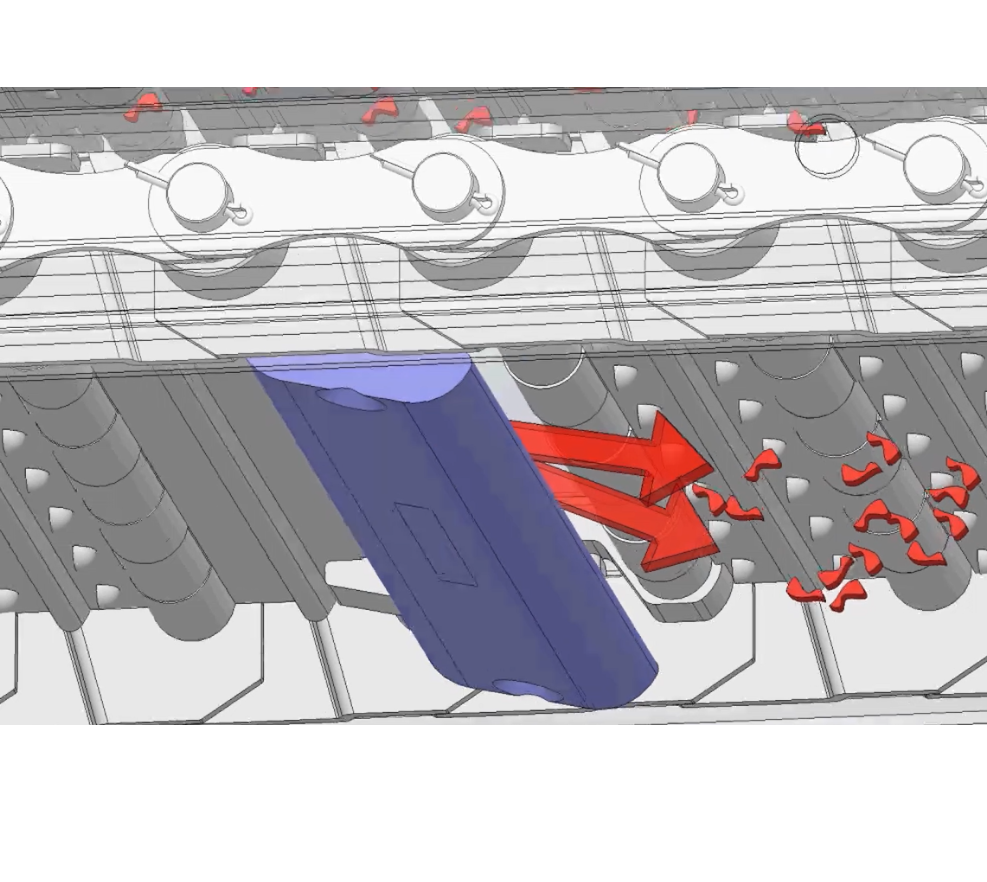

4. LiveLink eliminates chip clogging

Chips accumulating on the conveyor after filtering are gathered by the patented LiveLink system and a special scraping board, and then placed on the belt and released outside the machine.

Achieving SDGs with LNS ECO

LNS is committed toward reducing environmental burdens through reducing energy consumption. Turbo MH uses just a single motor to drive the conveyor and automatically clean the filter, significantly reducing power consumption. The amount of waste coolant is reduced by constantly cleaning the filter, which can help to significantly reduce your environmental burden. This can also substantially reduce how often the tank must be cleaned, which can play a significant role in improving work environment safety and health.