- Peripherals 2018/05/30 UP

-

Setup and centering time reduction by 90% (max.)

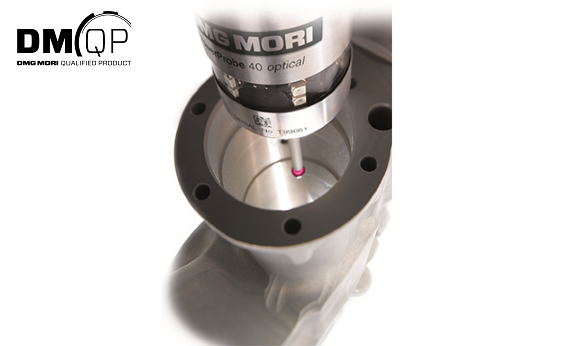

Automatic centering and tool measurement by Renishaw's probe system requires only 1/10 of time compared to manual measurement. It's very effective and saves a significant amount of cost. When you need to discard or re-machine the material, it would reduce productivity and profit. Renishaw's probe system enables "right first time", reduces cost, and increases profit.

*Please contact our sales team for details.

*Manufacturer: Renishaw (UK)

Features

1.Infrared data communication probe system

Independent from cable connection. No limit to machine movement.

2.Verified and patented kinematic structure

Kinematic structure same as CMM probe head.

3.Modulated signal transmission

Reliable modulated optical signal transmission.Enhanced resistance to optical interference.

4.Water-proof and robust

Water-proof (IPX8) and robust matching to machine tool environment.

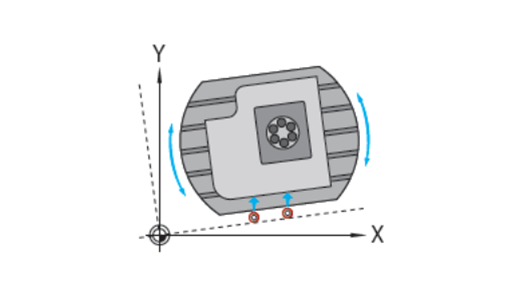

Centering, set-up measurement

Automatic on-machine measurement of position and alignment of components.

- No expensive fixture needed. Eliminates errors of manual centering.

- Quick design and introduction of a new machining process in response to new customer's demand.

- Less set-up time, better quality, less discarded material.

Automatic on-machine measurement replaces manual tool measurement.

- Eliminates errors of manual measurement. No need to input measurement data manually.

- Measures height offset and checks if tool length is within tolerance.

- Less set-up time, better quality, less discarded material.