- Peripherals 2018/05/30 UP

-

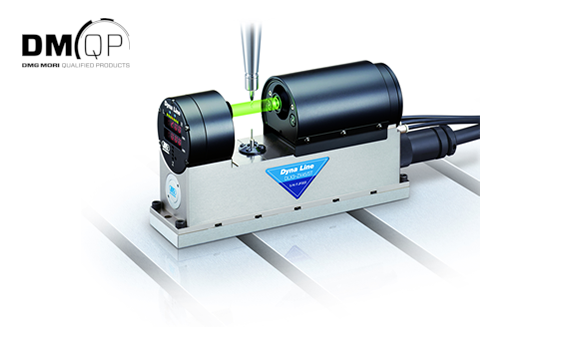

A high-speed, high-accuracy, non-contact type in-machine tool measurement device with BIG's original T-line sensor.

High-performance line sensor enables measurement of rotating tools, which is called "scanning measurement". It detects the position of a curved tool tip such as radial end mill accurately and automatically. Equipped with world premier technologies "tool run-out measurement" and "tool profile measurement", you can detect tool breakage and manage tool wear in numbers. This will contribute to reduction of insufficient machining and extended tool lifetime.

*Please contact our sales team for details.

*Manufacturer: BIG Daishowa (Japan)

Features

1.Easy operation

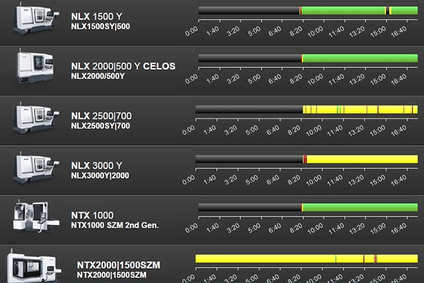

Measurement monitoring on DMG MORI's operation panel (ERGOline only).

2.A wide range of measurement functions

T-line sensor enables measurement of tool length, tool diameter, tool run-out, tool wear, and tool management. In addition, you can monitor the status of attached tools and spindle accuracy by Z-axis displacement measurement and spindle's dynamic run-out measurement with a test bar.

3.High-precision measurement

Non-contact measurement during tool rotation enables measurement of tool length and tool diameter at almost machining status by taking spindle's expansion and run-out into consideration.

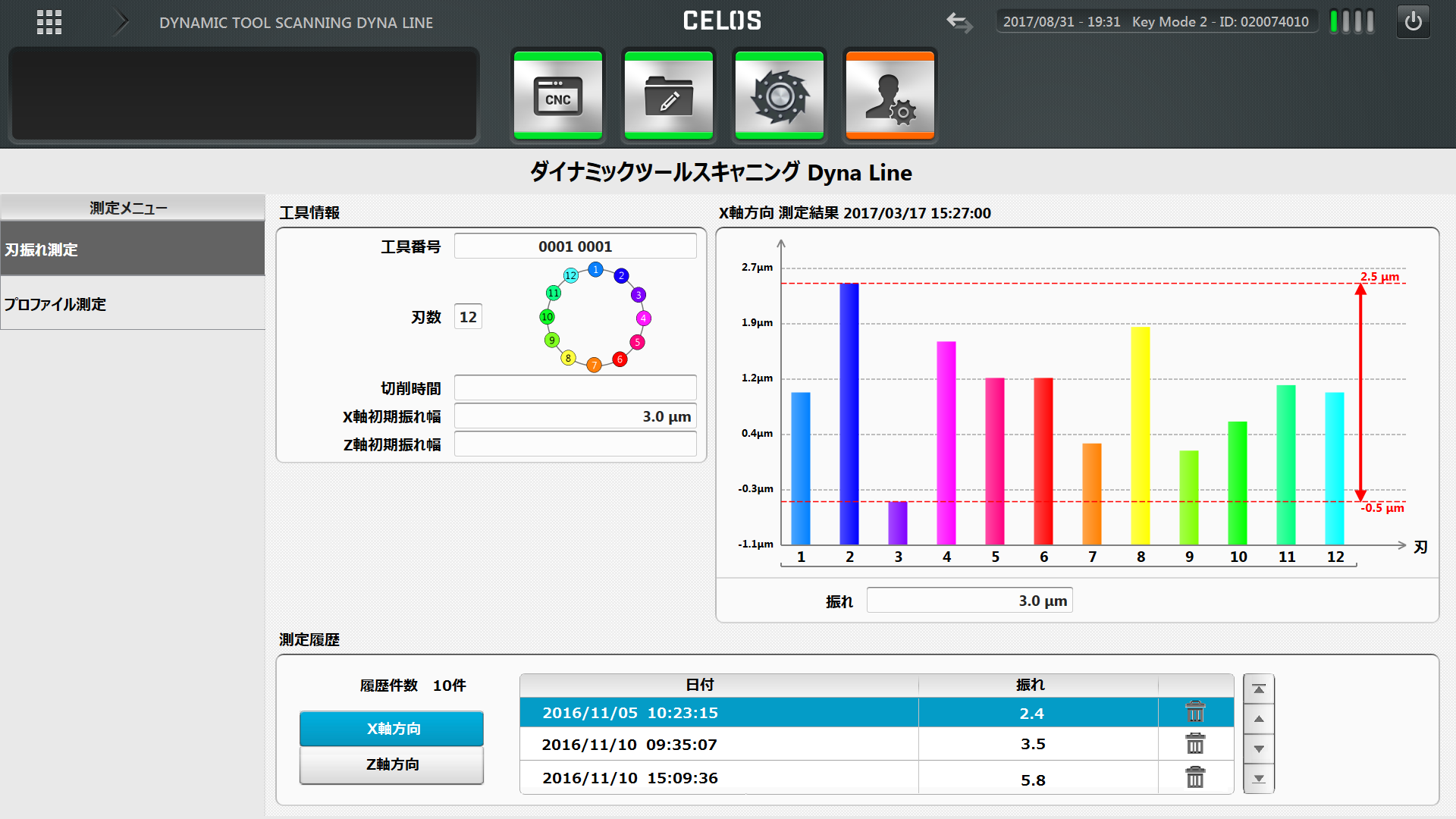

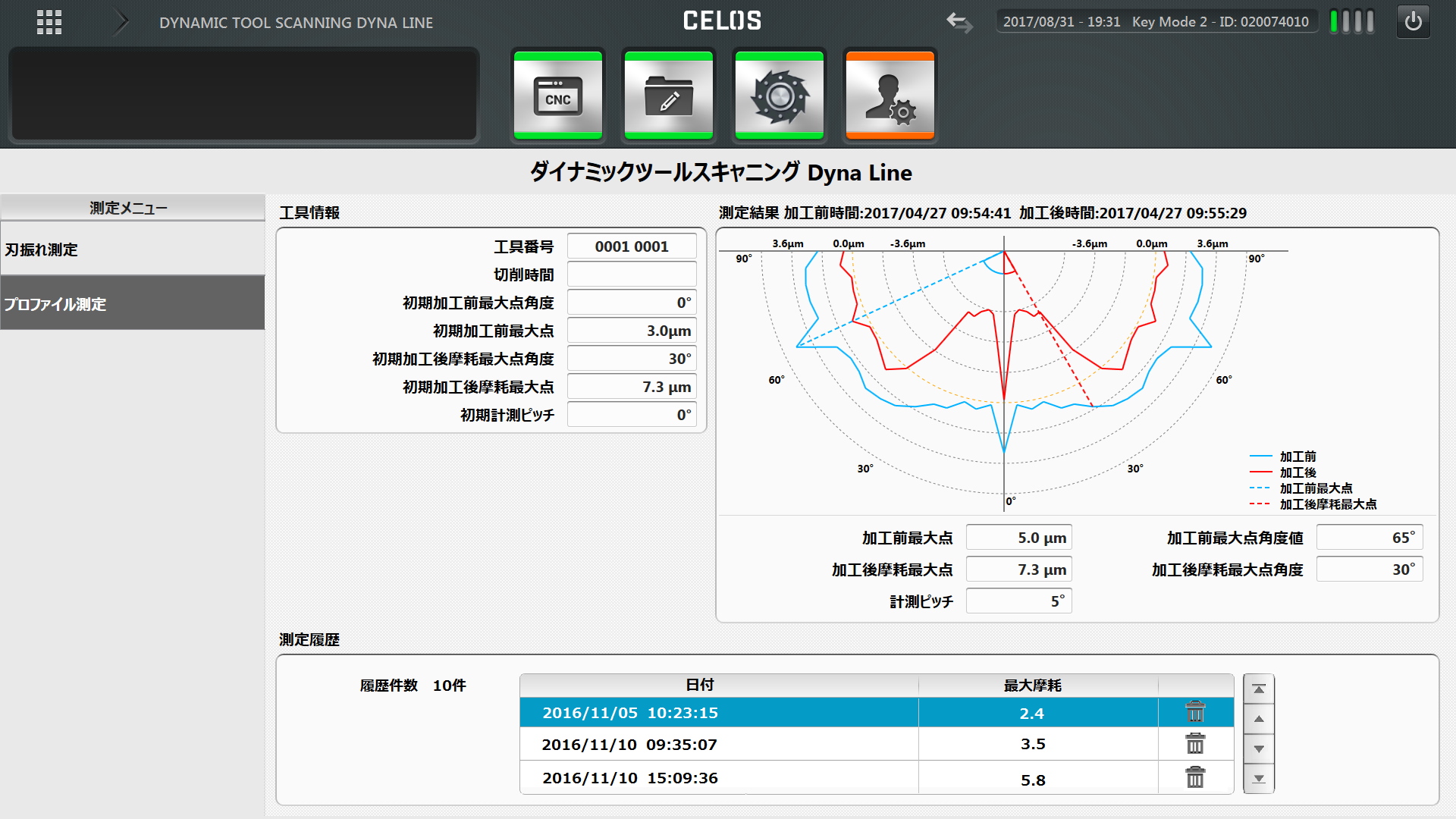

Screen shot of operation panel (ERGOline)

Tool run-out measurement

Profile measurement

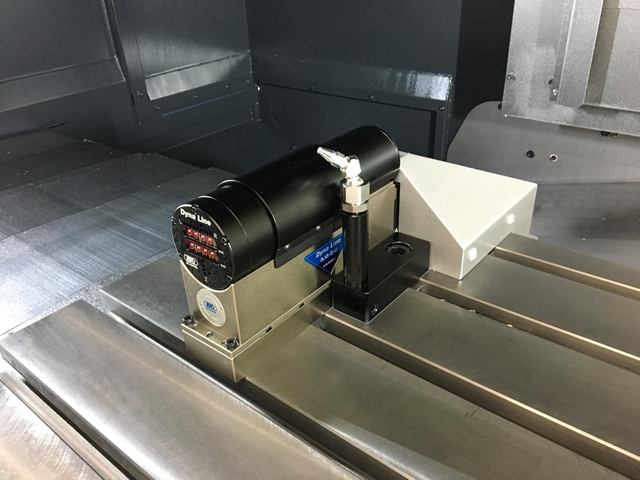

Mounting on a machine tool

(Model: Vertical Machining Center NVX 5000)