- Topics 2017/05/25 UP

-

- Tag

-

- Automation

- Workpiece handling

- Pallet handling

- Loader system

- Productivity improvement

The modern manufacturing industry is faced with great challenges such as reduction of lead time until market entry of products, flexibility to handle high-mix low-volume production and minimization of costs. To tackle the issues, factories need to be streamlined, namely, a comprehensive approach is required to boost productivity. Automation at shop floor is significantly increasing importance every day.

In this article, the fundamental knowledge about automation and the benefits are described. The vol. 4 focuses on the concrete installation process of automation systems (described in the vol. 1 to vol. 3), and the common issues.

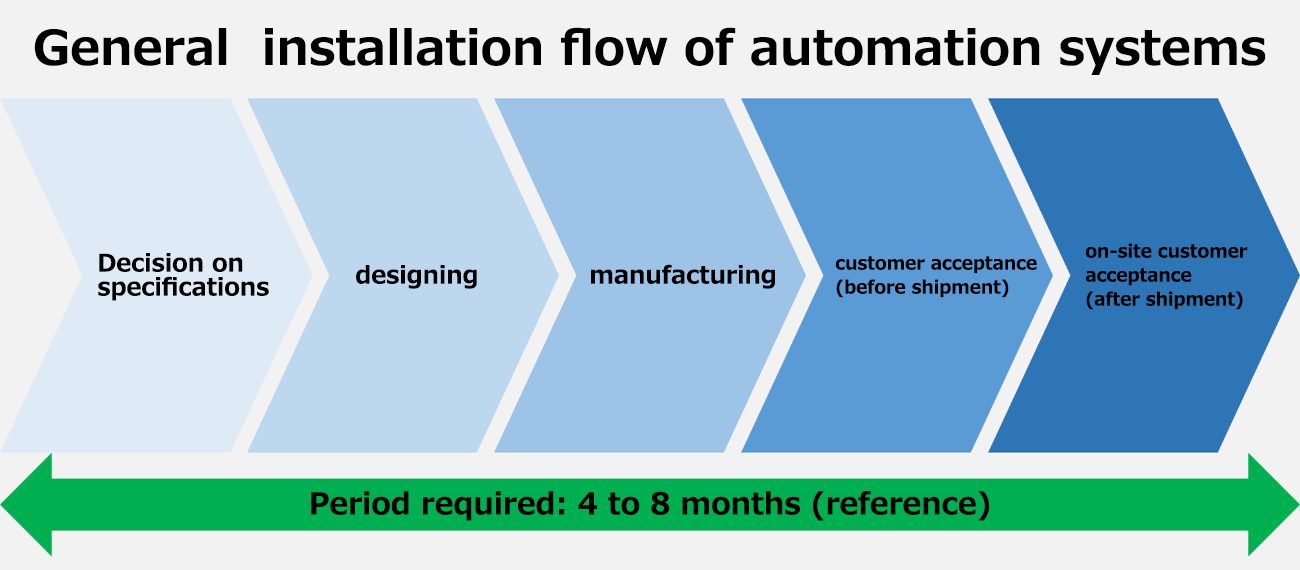

Installation flow of automation system

The general installation flow of automation systems at the shop floor is as follows.

In the beginning, you consult with machine tool manufacturers or automation system manufacturers, but it usually takes a long time to complete the installation. The required period is a reference as it actually depends on a system scale to a large extent. For a machine built-in automation system and a modular automation system (described “Standard Automation” and “Cells” in the vol. 3), it takes some four to six months, and for a customized system (“Systems” in the vol. 3) approximately six to eight months.

General issues at the time of installation and DMG MORI’s solutions

This content is for members only