- Masterpiece in the world 2024/04/19 UP

-

Masterpiece in the world #36

Drilling at unparalleled speed

The "LOGIQ3CHAM" 3-blade ultrafast replaceable head drill(ISCAR)

- Tag

-

- Chip disposal

- Chatter prevention

- High-speed machining

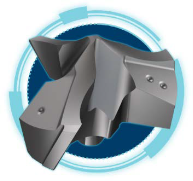

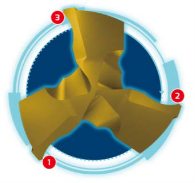

Drilling and boring. These two machining processes are very frequently used on workpieces in a wide range of fields. In some cases, they account for more than half of all machining processes. "LOGIQ3CHAM," a 3-blade ultrafast replaceable head drill developed by ISCAR (a carbide cutting tool manufacturer), can help to accelerate and streamline these machining processes and increase productivity. It is the first 3-blade replaceable head drill in the world, and is capable of high-speed drilling using three effective blades.

The world's first 3-blade replaceable head drill improves productivity approximately 50% compared with normal 2-blade machines

LOGIQ3CHAM is the world's first 3-blade replaceable head drill. The highly durable drill body and wear-resistant carbide head allow for consistent and reliable machining with accurate and smooth penetration to the target point.

Proprietary thinning minimizes blade run-out, for highly accurate drilling with no curvature or tipping. The chip pocket features an original design and, together with the flute groove, ensures smooth chip ejection. Finally, the unique curved shape of the cutting edge allows for a high degree of cylindricity.

LOGIQ3CHAM is equipped with three effective blades for unparalleled drilling speed, and can be used to increase productivity up to 50% compared with standard 2-blade replaceable head drills. The cutting edge stays in contact with the workpiece for a shorter amount of time than 2-blade machines, reducing the load on the blade. The pocket is designed to prevent plastic deformation and increase heat resistance, for a longer tool life even under extreme conditions.

Simple and fast head replacement to minimize machine stopping time

LOGIQ3CHAM has a machining diameter from Φ12 mm to Φ25.9 mm, and replaceable drill heads are available in a range of sizes in 0.1 mm increments. It also supports a wide range of edge shapes, including steel, cast metal, ferrite stainless steel, and martensite stainless steel. Edges are sharpened to maintain a level of cutting performance equivalent to that of a 3-blade solid drill.

One of the benefits of LOGIQ3CHAM is that the drill head can be easily replaced by anyone, while still attached to the machine. The core height does not need to be adjusted, resulting in significantly reduced machine stopping times compared with the time required to replace the blade on a 3-blade solid drill.

A 2-blade solid drill is often used after regrinding, and this requires a lot of work and time spent on stopping the machine to remove and attach the drill, readjust the core height, and keep grinding records. There are even cases where cutting conditions must be reduced around 80% in order to simplify accuracy adjustments. However, this is not the case for LOGIQ3CHAM replaceable head drills, which can reduce costs and also maintain consistently accurate machining.

LOGIQ3CHAM can increase rotary feeding six times over and significantly reduce costs

LOGIQ3CHAM is used by a wide range of customers all over the world in fields such as automobiles, heavy machinery, construction equipment, and heavy electric machinery. Following are some actual examples of introducing LOGIQ3CHAM to increase productivity.

Customer Case Example

<Case 1: Switching from a replaceable tip drill to LOGIQ3CHAM>

Company A had been using a replaceable tip drill to drill holes 20 mm in diameter in S50C. After switching to LOGIQ3CHAM, they were able to increase rotary feeding approximately six times over and reduce their cycle time from around 56 seconds to approximately 23 seconds. Their tool change time dropped to one-fifth the previous time, and tool life increased around 2.5 times over. The replaceable tip drill had also been causing chattering. They were able to eliminate this after switching LOGIQ3CHAM, which has three blades and provides consistent machining balance. They were ultimately able to significantly increase productivity and reduce costs.

<Case 2: Switching from a 2-blade replaceable head drill to LOGIQ3CHAM>

Company B had been using a 2-blade replaceable head drill to drill holes 14 mm in diameter and 35.6 mm in depth in S45C.

After switching to LOGIQ3CHAM, they were able to increase rotary feeding and cutting speed approximately two times over and reduce their cycle time from around 284 seconds to approximately 145 seconds. They were also able to increase tool life approximately two times over. They were ultimately able to increase productivity and significantly reduce costs.

<Case 3: Switching from a 2-blade solid drill to LOGIQ3CHAM>

Company C had been using a 2-blade solid drill to perform through-hole drilling operations in FCD450, creating holes 17.5 mm in diameter and 71 mm in depth. After switching to LOGIQ3CHAM, they were able reduce their cycle time from around 32 seconds to approximately six seconds. They previously needed to perform tool changes after around 2,000 holes, but this increased to approximately 7,000 holes after switching to LOGIQ3CHAM, increasing tool life around 3.5 times over. They were able to dramatically improve productivity by significantly reducing cycle times and the amount of tool change work.

ISCAR metal mold technology is the key to producing unparalleled "LOGIQ3CHAM" cutting tools

LOGIQ3CHAM is a truly remarkable cutting tool. Its unparalleled speed, which can only be described as "ultrafast," helps to improve productivity. It is the result of ISCAR's wide range of superior technologies and creative ingenuity.

A 3-blade machine generally has a lower core thickness than a 2-blade machine, which reduces the durability of the tool itself. It is for this reason that a 3-blade replaceable head drill like LOGIQ3CHAM was thought to be an impossibility. However, ISCAR continued to develop its concept and refine such aspects as the body material, grinding technology, head shape, shape of the pocket and flute to smoothly process chips, installation method, and internal coolant to most efficiently cool the product. After more than seven years, development of LOGIQ3CHAM was finally complete.

ISCAR's unique metal mold technology was key in so accurately forming such a complex shape. LOGIQ3CHAM is now the first and only 3-blade replaceable head drill in the world.

An extensive lineup of highly durable products to maximize LOGIQ3CHAM performance

It is important to consider machine tool and clamp durability when using LOGIQ3CHAM. Using LOGIQ3CHAM with highly durable machines can significantly increase productivity and reduce costs. In other words, highly durable machine tools from DMG MORI are perfect for maximizing the performance of LOGIQ3CHAM.

*It is recommended to use LOGIQ3CHAM with BT40 or above machines.

ISCAR invests approximately 4% of sales each year in research and development, and continues to produce innovative cutting tools under its slogan, "Where Innovation Never Stops!"

ISCAR is a carbide cutting tool manufacturer headquartered in Israel. It produces a wide range of innovative products based on creative ideas and advanced technical capabilities. ISCAR cutting tools are used in a wide range of fields including the medical industry, automotive industry, energy industry, aircraft industry, and precision machinery industry, and the company is ranked second worldwide in terms of market share.

ISCAR is also a core member of IMC (International Metalworking Companies), a group of cutting tool manufacturers consisting of 15 major tool manufacturers from all over the world, including TaeguTec (South Korea), Ingersoll (US/Germany), and Tungaloy (Japan).

ISCAR's greatest strengths are its value-added products and its ability to research and develop such products. The company invests approximately 4% of sales each year in research and development, and continues to develop new products under its slogan, "Where Innovation Never Stops!" New products and projects account for approximately 40% of the company's actual annual sales.

ISCAR has locations in 60 countries all over the world, and operates ISCAR Japan Ltd. as its sales location in Japan.

| ISCAR Japan Ltd. Senri Asahi Hankyu Bldg. 20F, 1-5-3 Shinsenrihigashi-machi, Toyonaka-shi, Osaka, 560-0082 TEL: 06-6835-5471 |

The article introduces the DMG MORI selection of masterpiece equipment in the world.