- Masterpiece in the world 2021/02/02 UP

-

Masterpiece in the world #33

Making measures while clamping workpieces

Contributing to labor saving and higher productivity

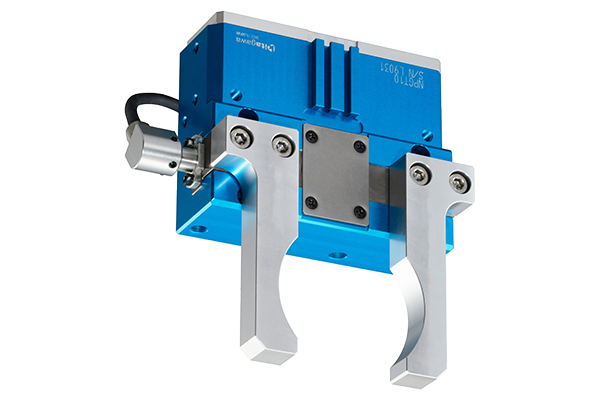

Thin 2-jaw Parallel Gripper Scale Specification “NPGT_S”

- Tag

-

- Peripherals

Automation production lines need inspection in machining processes, from material supply to machining completion, to check that workpiece forms comply as specified. This requires places, inspectors and time to make measurements, which as a result leads to lower productivity.

Foreign substance and/or chips can adhere to gripped areas. When workpieces are not appropriately clamped, it can result in suspension of automation lines due to machining failure caused by a fall of workpiece during transfer or poor workpiece positioning in the following process.

Here is the thin 2-jaw Parallel Gripper Scale Specification “NPGT_S” of Kitagawa Corporation to tackle such a problem.

High-accuracy, high-durability achieved by the know-how on chuck production for lathes

This content is for members only