- Tips on machining 2016/11/14 UP

-

Tips on machining vol.3

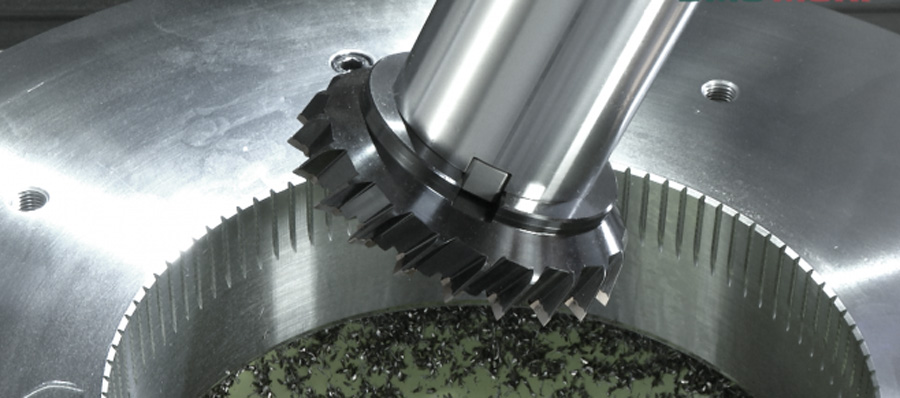

Gear skiving

-Machining requiring dedicated machine made possible with general-purpose machine-

- Tag

-

- Gear milling

- skiving

Gear skiving is a gear machining method in which a gear is machined by synchronization of turn-mill spindle rotation and workpiece rotation.

The idea of skiving was originally suggested as early as around 1950, but at that time it did not come into practical use due to its insufficient machining accuracy. The recent progress of synchronous control technology for machine tools has enabled it to become practically applicable.

Conventionally, gear machining requires dedicated machines such as a gear hobbing machine and a gear shaper, and their expensive initial costs and large installation space are challenges facing many gear manufacturers.

Gear skiving, on the other hand, allows gear machining to be performed on a machining center or a turning center, thereby reducing equipment costs and overhead costs. Skiving also allows the whole machining to be done in one chucking, helping users to save time and effort for setups and workpiece changes, and improving machining accuracy.

In recent years a machine interface for skiving has been remarkably progressed. Today’s easy-to-use interactive interface requires no special knowledge.

This content is for members only