- Tips on machining 2019/09/18 UP

-

- Tag

-

- Chatter prevention

- Milling

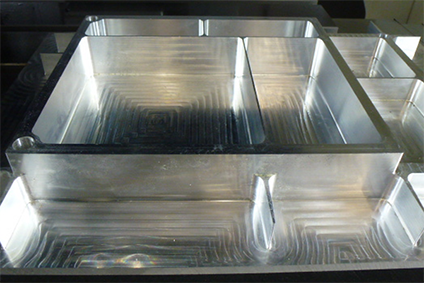

A face mill is a convenient tool capable of efficient surface cutting with its large O.D. However, as it cuts a large volume at a time, cutting resistance also becomes large.

In general, face milling is not difficult when the overhang is short and workpiece rigidity is high. However, when the overhang is long, machining becomes extremely difficult because the feed force and main cutting force are generated in the bending direction of the tool. This causes intermittent motion at the tool tip and generates chatter. So many of you may struggle with setting the optimal cutting conditions.

Chatter is affected by the magnitude of cutting resistance and the cutting direction. The threshold of chatter can be raised, more specifically, chatter can be suppressed by reducing cutting resistance so that the amount of tool bending becomes smaller, or by reducing the feed force and main cutting force.

We conducted tests and measurements on cutting resistance under various conditions to identify what properties and values it shows on each condition, using face mills with different rake angles and cutting edge angles. Based on these test and measurement results, we present three key points to suppress chatter in face milling, and show the criteria of stable machining by holder length as a reference.

We trust that the information will be helpful in determining the specifications of cutting tools. So please read through to the end.

(1) Increase rake angle

This content is for members only