Rotary Pallet Storage SystemRPS SYSTEM

Surprisingly compact,

full use of factory space

Having a compact and simple structure, RPS is the best solution for customers who have not been able to install automation systems due to space limitations in their shops, or those hesitate to automate their production because of the negative image of automation: complicated.

RPS 5 + NHX 4000 3rd Generation

RPS 14 + NHX 4000 3rd Generation

RPS 21 + NHX 4000 3rd Generation

Video

Highlights

- Space-saving

- A full-scale automated system can be built in a small space. This system provides the most number of pallets per area with good setup performance while saving space.

- Long-term unmanned operation

- With a capability of long-term automatic operation, the system allows you to save on labor costs, for example, by conducting unmanned operation at night or on weekends.

- Shorter installation lead time

- Thanks to its integrated construction, the system can be installed in a short time.

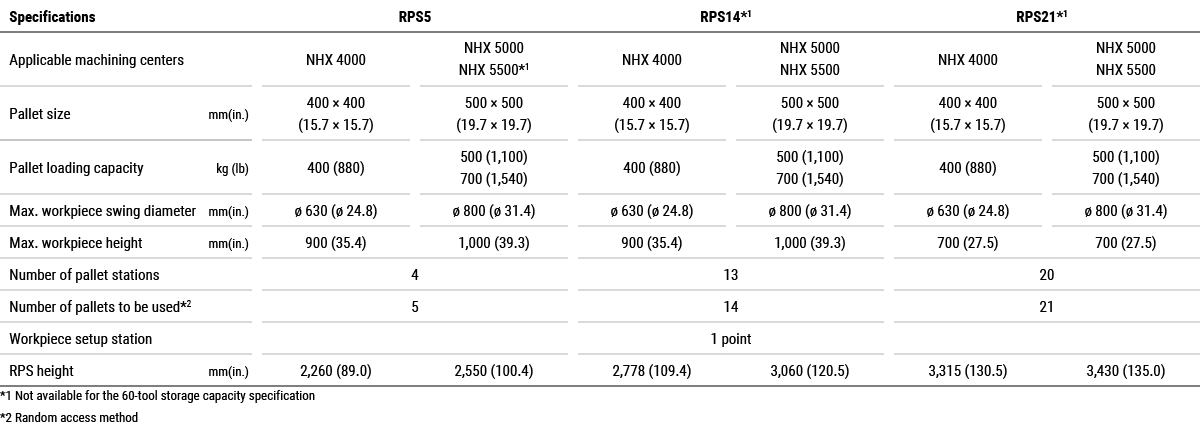

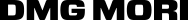

Variations

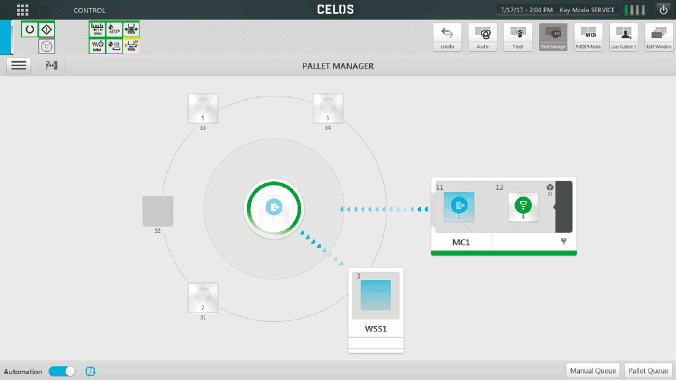

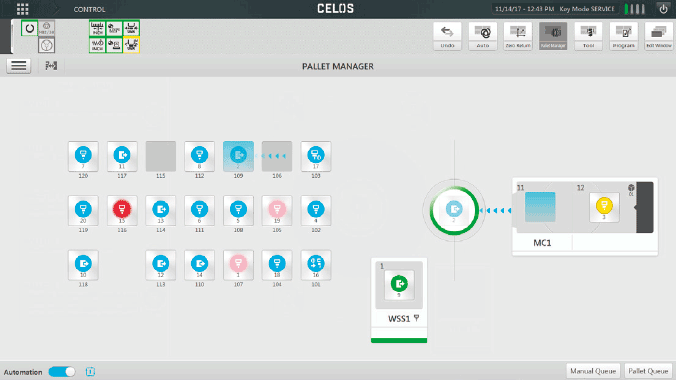

Simple and Easy Operation with CELOS

Setup operation is now possible not only with the conventional handy controller, but with CELOS on the machine.

The use of CELOS also allows operation and management of both the machine and RPS.

Featuring a large touch screen, CELOS offers intuitive operation just like a smartphone.

PALLET MANAGER, one of CELOS applications, ensures hassle-free operations and shorter setup times.

- Easy check of pallet status on CELOS

-

- Displays the entire system layout in an easy-to-see manner

- Able to check the latest pallet status and shorten setup time

- Able to transfer pallets by drag and drop of the pallet icon on the screen

- Tool check to prevent troubles in advance

-

- Automatically identifies and displays tools that are not suitable for machining by central tool management

- Prevents machining failure and troubles caused by tool breakage

- Improves productivity by minimizing problem-caused rework

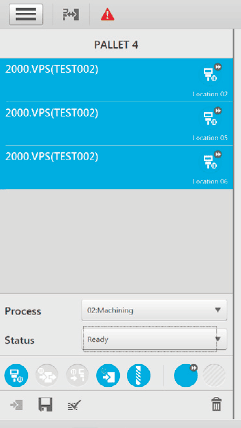

- High flexibility to accommodate production changes

-

- Able to assign information on multiple workpieces to a single pallet

- Easy production adjustment / rescheduling on CELOS to respond flexibly to sudden schedule changes or urgent requests

Specifications