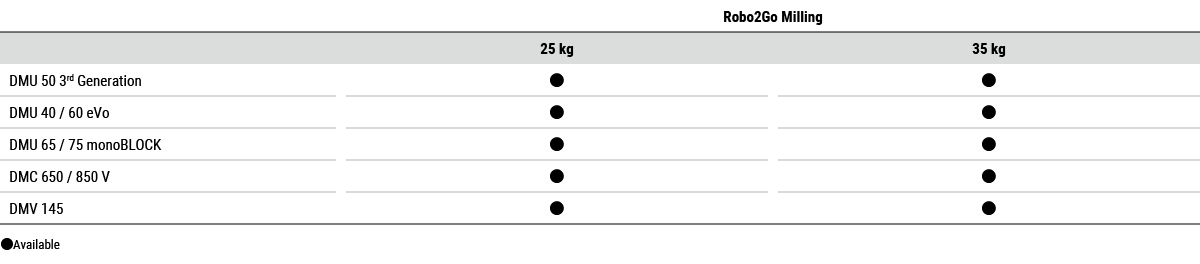

Robot systemRobo2Go Milling

Space-saving robot system for 5-axis machines and machining centers with a footprint of 4.4 m2 (47.4 ft2)

Robo2Go Milling is a robot system for milling operations in which the robot is positioned on the side of the machine, ensuring high accessibility to the machine and operation panel. It can be used to automate 6-sided complete machining.

Video

Highlights

- Various Robo2Go settings are available via CELOS APP. Setting up a workpiece takes less than 5 minutes.

- Robust construction for all needs: robot payload 25 kg (55 lb.) <option 35 kg (77 lb.)>

- Supports workpieces from ø 20 to 200 mm (ø 0.8 to 7.9 in.)

- Excellent accessibility to the cabin, operation panel and workpiece stocker

- Different types of workpieces can be placed in the same workpiece stocker

- Workpiece handling from the side of the machine ensures excellent accessibility and workability

- External and internal of workpiece gripping

- Expandable work trays can be mounted

- Reduced pressure specification for gripping thin-walled workpieces

Workpiece handling from the side of the

machine ensures

excellent accessibility

and workability

- Robust construction for different requirements:

optional 25 kg (55 lb.) or 35 kg (77 lb.) robot payload - Handling of workpieces with dimensions from 20 to 200 mm (0.8 to 7.9 in.)

<other dimensions available as an option> - External and internal gripping as standard

- Customizable workpiece trays

- Reduced pressure specification for thin-walled workpieces

- Excellent accessibility to workpiece storage

- Optional:

– Workpiece stacking

– Turning station for automated 6-sided complete machining

Specifications