Robot systemRobo2Go Turning

Space saving robot system allows you to construct automation system quickly

Robo2Go Turning is a robot system that automatically supplies and removes materials in combination with a turning center.

Since it is installed in front of the machine, it can be used flexibly by moving it to another machine depending on the application. The high-precision sensor system can recognize the workpieces, making it ideal for high-mix low-volume production.

Video

Highlights

- One app for uniform control of all Robo2Go variants, setting up a new workpiece < 5 minutes

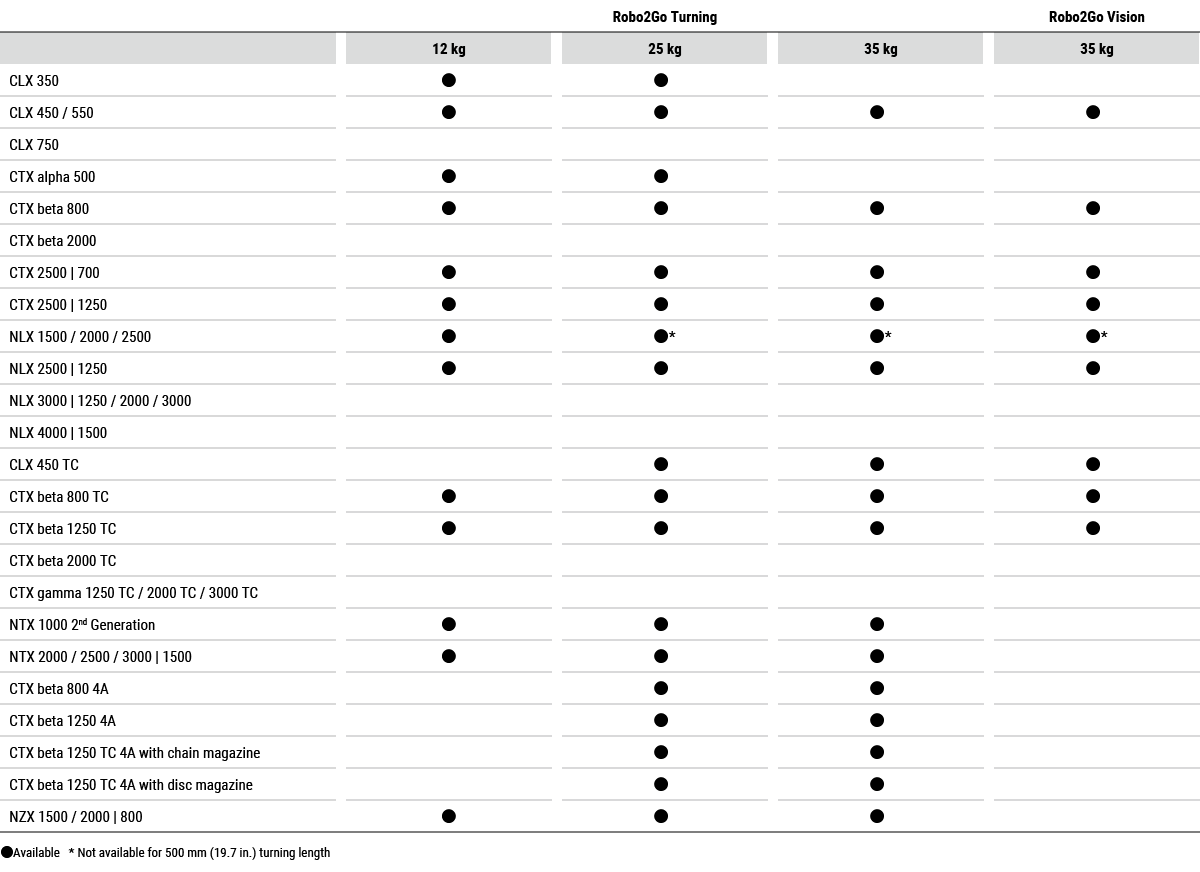

- Robo2Go Turning, robot payload 12 (26.4), 25 (55) or 35 kg (77 lb.)

- Rapid changeover from chuck to shaft parts

- Robo2Go Vision can be mounted to recognize workpieces thanks to a highly accurate sensor system: Robot payload up to 35 kg (77 lb.)

Robo2Go Turning:

Automation system for turning machines

Flexible workpiece handling for payloads up to 35 kg (77 lb.)

- Three models to meet different needs: 12 kg (26.4 lb.) / 25 kg (55 lb.) / 35 kg (77 lb.) robot payload

- Suitable for handling shaft workpieces <ø 20 to 170 mm (ø 0.8 to 6.7 in.)> and chuck workpieces <ø 20 to 175 mm (ø 0.8 to 6.9 in.)>

- External and internal gripping

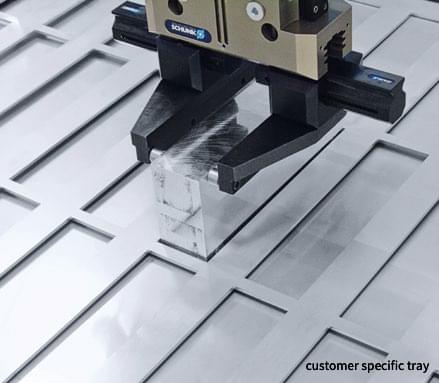

- Customizable work trays

- Workpieces can be stacked

- Can be combined with bar feeder

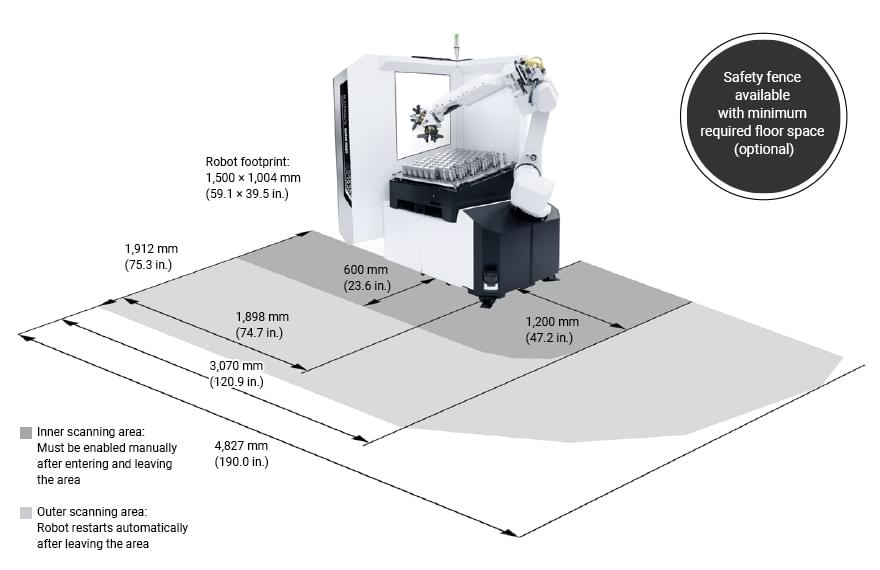

- Laser scanner monitoring creates a work environment without safety fences

- Automatically reboots after entering external scanning area

Gripper

The right solution for all situations

- 2-finger gripper

-

- Chuck & shaft components

- Internal & external grip

- ø 20 – 170 mm (ø 0.8 - 6.7 in.)

- 3-finger gripper

-

- Chuck components

- Internal & external grip

- ø 25 – 175 mm (1.0 - 66.9 in.) <external>

- 4-finger gripper

-

- Shaft components

- External grip

- ø 20 – 150 mm (ø 0.8 - 5.9 in.)

- Special gripper

-

- Extended diameters

- Safe connection is possible

Option

- Workpiece tray for shaft parts

- Additional workpiece storage

- Pressure reduction for gripping sensitive workpieces

- Work trays with workpiece stacking capability

- Safety fence

- etc.

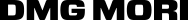

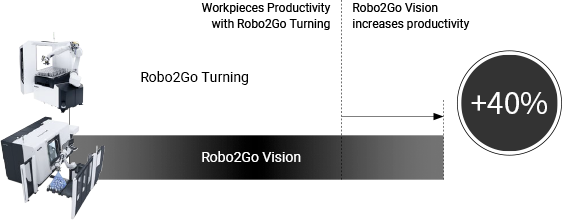

Production assistant with high-precision vision sensor

- Robot payload of up to 35 kg (77 lb.)

- Cylindrical chuck workpieces from ø 25 to 175 mm (ø 1.0 to 6.9 in.)

- High-definition cameras allow for rapid sharing of materials and removing

finished products - No special work storage is required

- Reliable 3D camera detection (ideal for multi-job functions)

- Camera facilitates and speeds up the setup of new workpieces

- Automatic workpiece detection by camera based on specified workpiece

diameter and length - Work storage capacity (40% improvement)

Specifications