Robot systemMATRIS Light

Robot system to automate high-mix low-volume production in a short time

MATRIS Light is a freely movable human-collaborative robot system mounted on a hand cart.

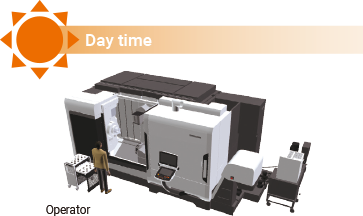

The system can be moved when not in use and used with the necessary equipment when automation is required, thus enabling automation of high-mix low-volume production in a short time and supporting production through automation even in urgent machine operation when the operator is not available.

MATRIS Light + NTX 1000 2nd Generation

Video

Highlights

- A freely movable robot system with a robot arm & workpiece mounted on a cart

- No major infrastructure changes required for robot installation

- Easily automated with a setting time of only 5 minutes when needed

- Robot and workpiece mountable on separate carts to enable setup of next workpiece during operation

- Easy direct teaching for the robot that requires no special expertise

- Max. transfer weight: 5 kg (11 lb.)

- Collaborative robot requires no fence installation

- No extra space required for the automation system: Robot cart size of 600 × 900 mm (23.6 × 35.4 in.) is comparable to the work space of an operator

- Compatible with a wide range of DMG MORI machines

- Handy ways to use MATRIS Light!!

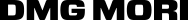

- 1. Automate when operator is unavailable

2. Connect to a different machine every day

3. Operator in day time,

MATRIS Light in night time

Setup in 5 minutes

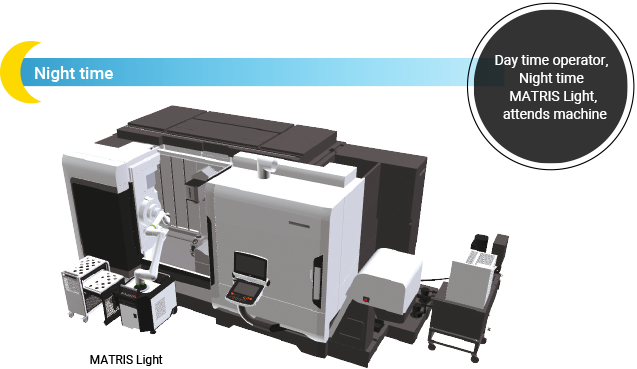

- 3-point Support Structure

-

Secured by the 3-point support structure

Secured by the 3-point support structure

- Plug & Play

-

Connect the power supply and air blow

Connect the power supply and air blow

・Power supply: 100 V to 240 V single-phase

・Air: 0.4MPa (58.0 psi) flow rate 50 L/min (13.2 gpm) Ethernet connection

Ethernet connection

・Ethernet cable

- High-speed Setup

-

Setup in only 5 minutes

Setup in only 5 minutes

-

Position compensation with tags (option)

Position compensation with tags (option)

- Position compensation with tags (option)

-

Tag

Tag Marker reading on the stocker

Marker reading on the stocker

-

Marker reading on the machine

Marker reading on the machine- Tag function available: reads the markers attached to the machines and adjusts the positions between the robot and the machine

- Intuitive Operation

-

Direct teach

Hold robot arm by hand, move to teaching

position (direct teaching mode) Easy to move among machines with the cart type structure

Easy to move among machines with the cart type structure

Suitable models

- 5-axis machine: DMU 50 3rd Generation / DMU 40 eVo / CMX 50 U

- Multi-Axis Turning Center: NTX 1000 2nd Generation / NTX 2000 2nd Generation / NTX 2500 2nd Generation

- 4-axis multi-axis machine: NZX 1500 / NZX 2000 / NZX 2500

- Horizontal machining center: NHX 4000 3rd Generation

- Vertical Machining Center: CMX 600 V / CMX 800 V / CMX 1100 V / i 30 V

- Turning Center: NLX 1500 / NLX 2000 / NLX 2500 / ALX 1500 / ALX 2000 / ALX 2500