Modular robot systemMATRIS

Modular robot system that requires no programming knowledge

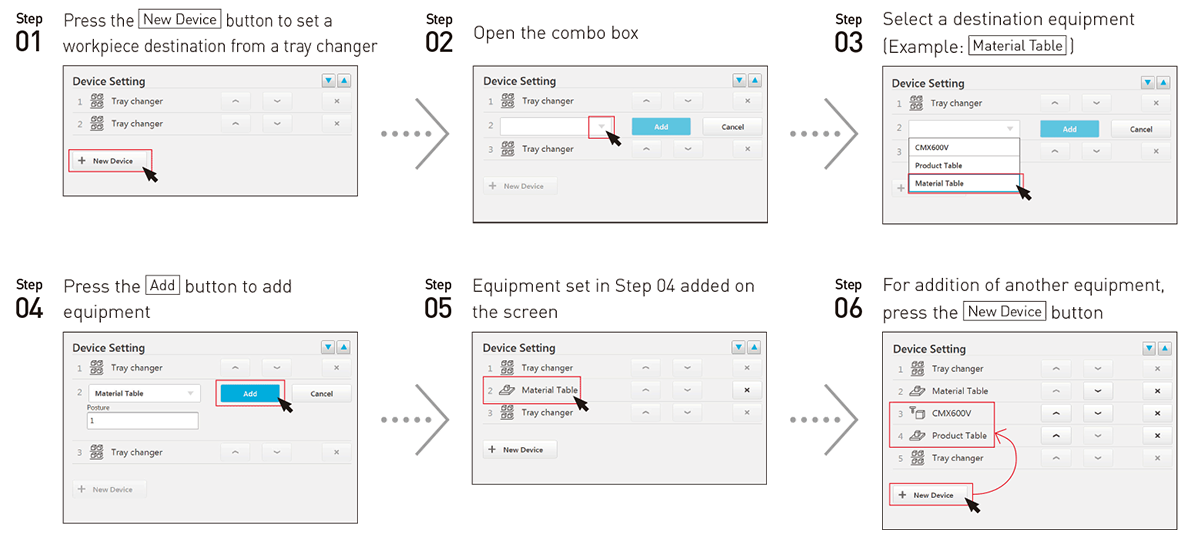

MATRIS controller, a dedicated system that connects modularized peripheral devices, robots, and the machine itself, eliminates the need for complicated program editing and allows system setups to be changed on a simple operation screen.

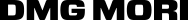

MATRIS + NVX 5100 | 50 2nd Generation

Video

Highlights

- Modularized and standardized sizes are available for each of the units that make up the system, such as conveyors, workpiece stockers, and in-machine measuring devices.

- Standardized peripherals ensure easy customization to meet your specific needs

- Flexibly accommodate system changes even after installation

- MATRIS controller for simple robot control

- DMG MORI provides the same maintenance and support as machines

- DMG MORI-certified selected peripherals with superior reliability, quality and performance

- Typical system packages available in advance

- Significantly shortened implementation time

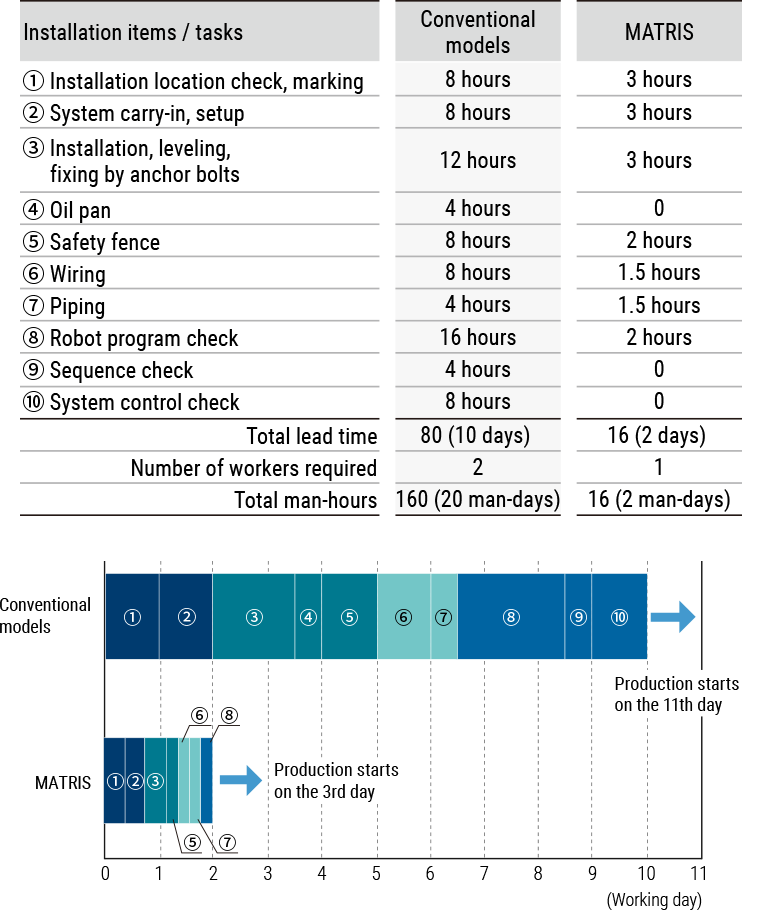

At the time of system installation

System construction lead time reduced by 80%

- The oil pan and the robot base are of integral construction, so no oil pan setup is necessary

- Consisting of modularized units, the system requires neither sequence check nor system control check at the installation site

- No advanced training in robot programming or operation is required*.

* Initial training required by law

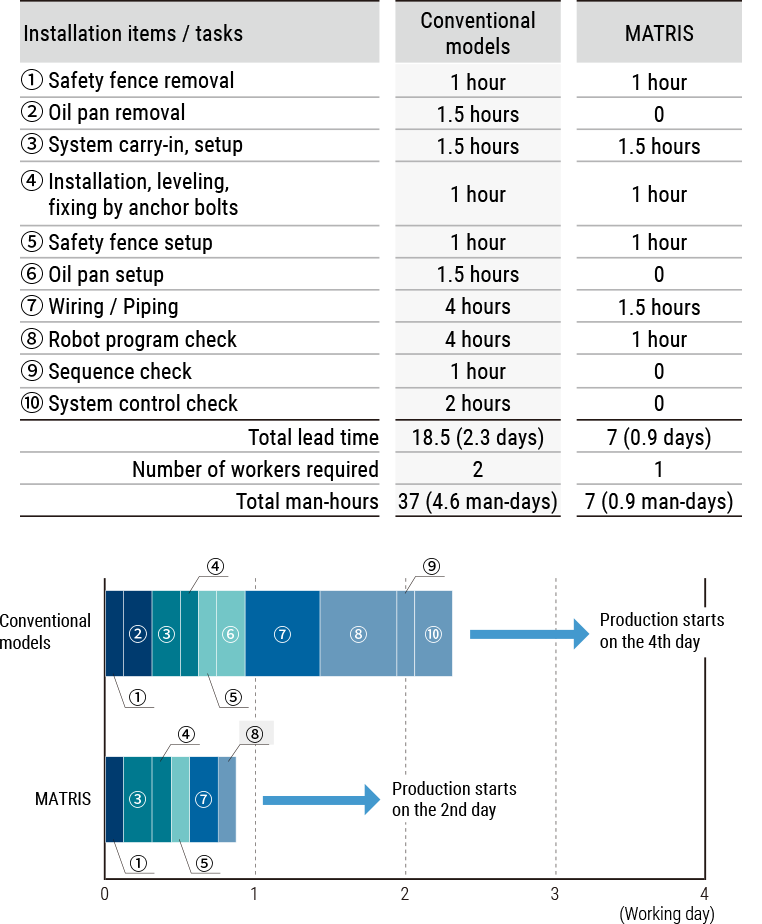

At the time of system change

System down-time reduced by over 60%

- The oil pan and the robot base are of integral construction, so no oil pan setup is necessary

- Consisting of modularized units, the system requires neither sequence check nor system control check at the installation site

- Standardized robot programs enable quick start-up and easy setup changes

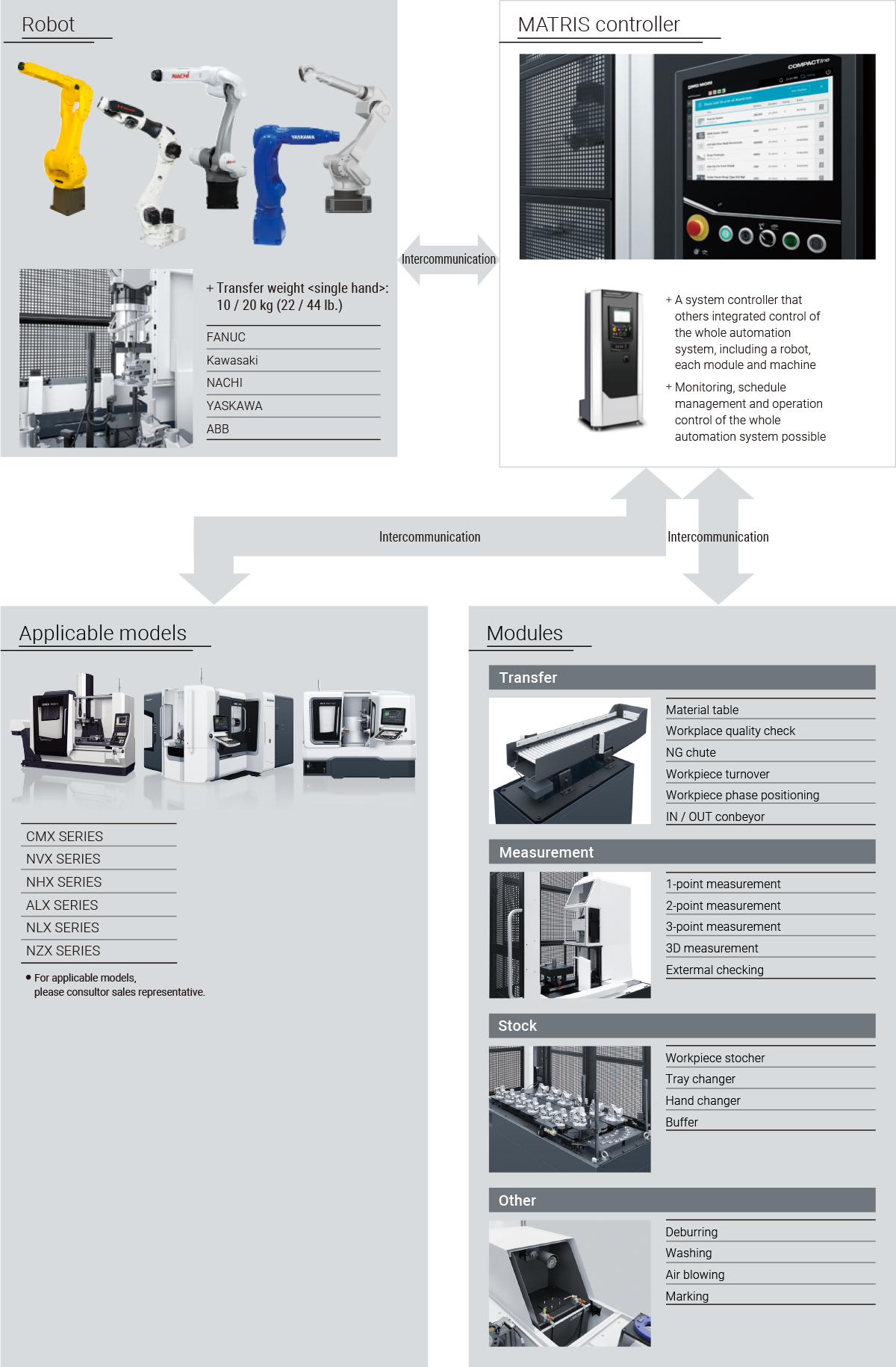

Structure of robot system

MATRIS controller – Perfect Solution for Automation Systems

MATRIS controller is a system that connects machines with various peripherals and robots via network to integrate monitoring, scheduling and production management.

The system solves issues about installation of automated systems, such as connections with peripherals and the system management and costs.

- Easy-to-see screen to monitor operation status of the entire system

- Easy-to-see screen layout enables operators to view all necessary information at a time

- Compact design contributes to space saving

- Provide common user interface with CELOS / MAPPS V for smooth and efficient operation

- Employ the MAPPS operation panel to offer the same long-term maintenance support as the machine

CELOS: Control Efficiency Lead Operation System

MAPPS: Mori Advanced Programming Production System

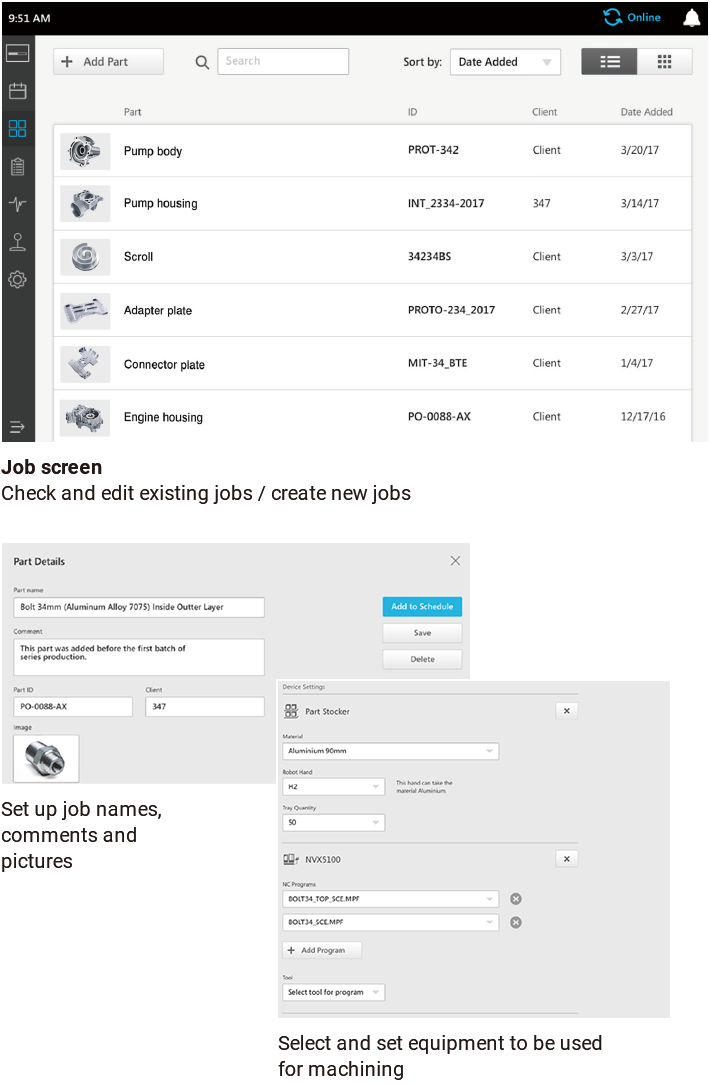

Innovative job management

MATRIS controller has the function for managing the operation on a job order basis,

so you can change the settings and operation on your own.

[Flow for creating new jobs]