Linear Pallet Pool SystemLPP SYSTEM

Pallet pool system that allows flexible construction of the optimal system for each customer

This is a system with a high level of automation, employing a modular design that increases the number of pallet racks, book machines, setup stations, and other components according to production details.

The system can be flexibly constructed to meet customers' requirements.

LPP system + NHX 6300 2nd Generation

Video

Highlights

- Reduction in setup time

- By placing multiple fixtures on the pallets in advance, no setup is needed when you receive repeat orders.

- Stable quality

- When you receive repeat orders, there is no need to re-attach fixtures, so there is nothing to affect stable machining accuracy.

- Reduced personnel costs

- Since the system allows long-term automatic operation, you can reduce personnel costs, for example by conducting unmanned operation at night.

- Easy production management

- The LPS 4th Generation control system allows you to manage production schedules flexibly, and to respond to urgent job requests.

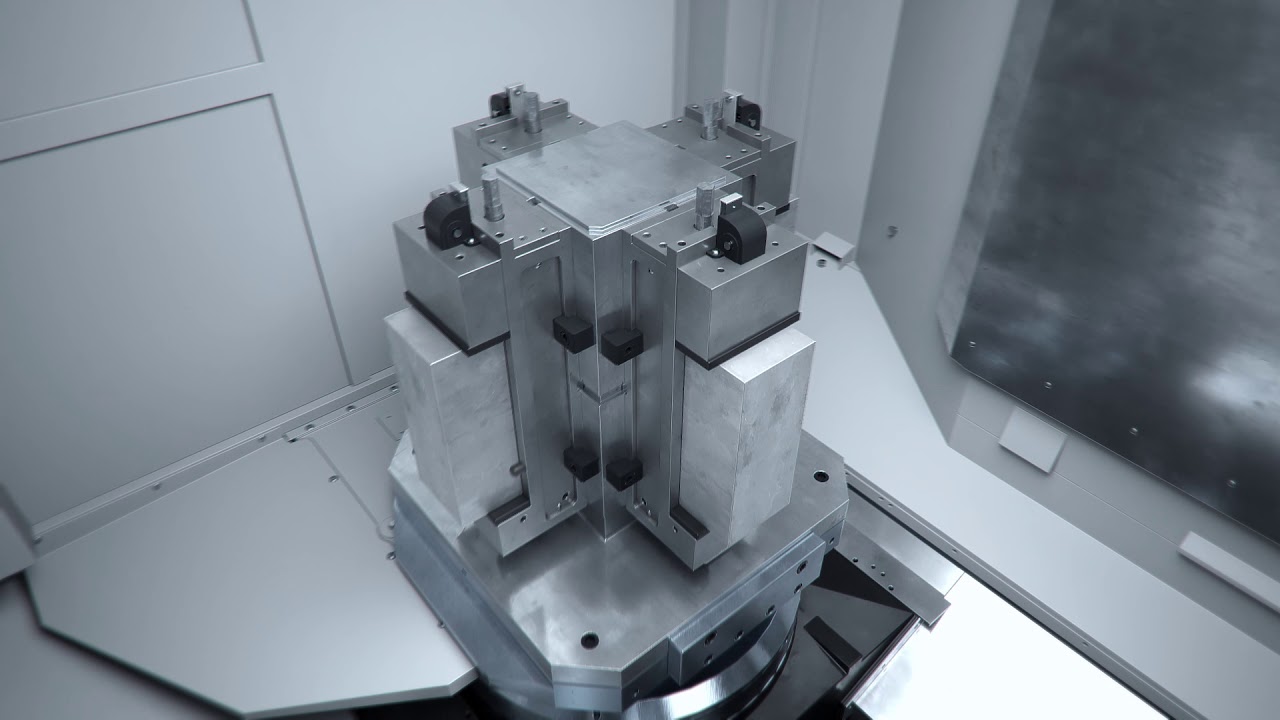

LPP’s features

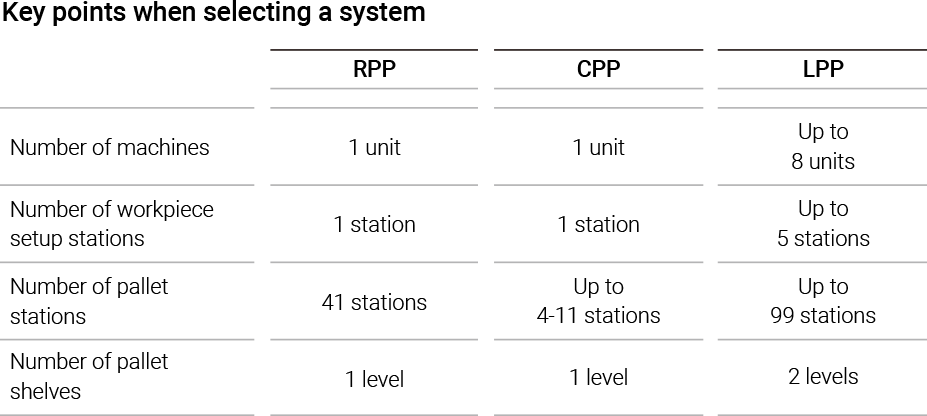

Among all the various systems which are available, the LPP system is the most suitable for multi-item, small to medium-lot production.

RPP: Round Pallet Pool, CPP: Compact Pallet Pool,

LPP: Linear Pallet Pool

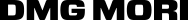

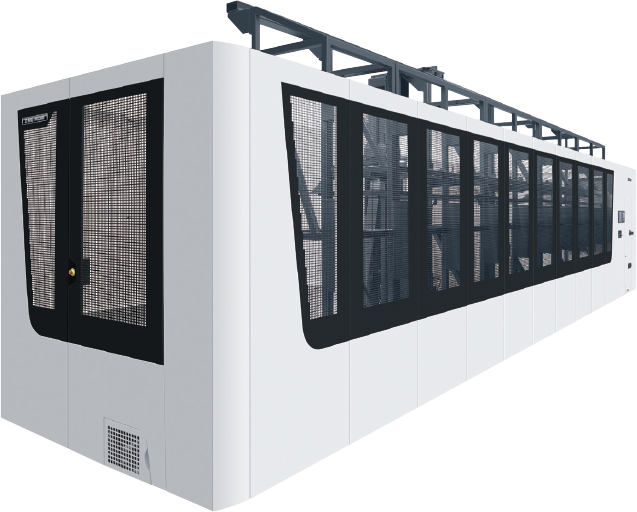

New Design with Beauty and Usability

The design pursues ease of use to reduce the burden of daily work.

The cover design is also aesthetically pleasing, allowing you to experience the joy of operation.

- Smoother door opening / closing to reduce operators' burden

- Improved visibility inside the LPP

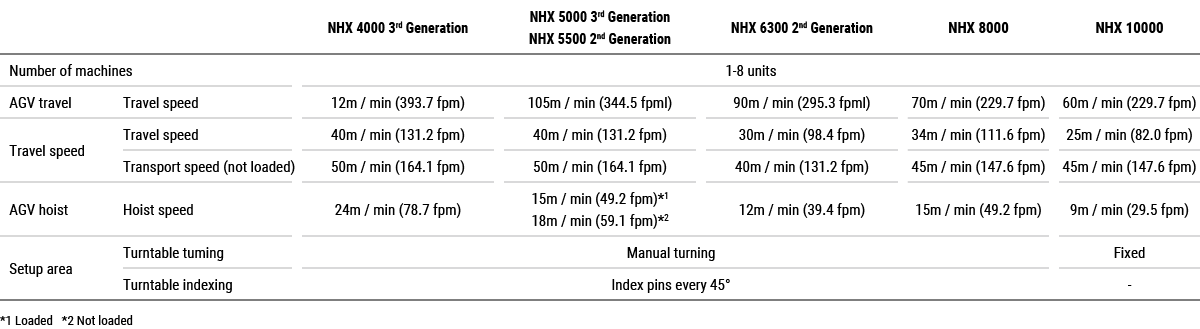

Specifications