- Masterpiece in the world 2016/10/06 UP

-

Masterpiece in the world #1

Laser tool measuring system capable of on-machine tool measurement and automatic detection of micro wear and breakage of rotary tools

- Tag

-

- Automation

- On-machine measuring system

Blum-Novotest (Germany)

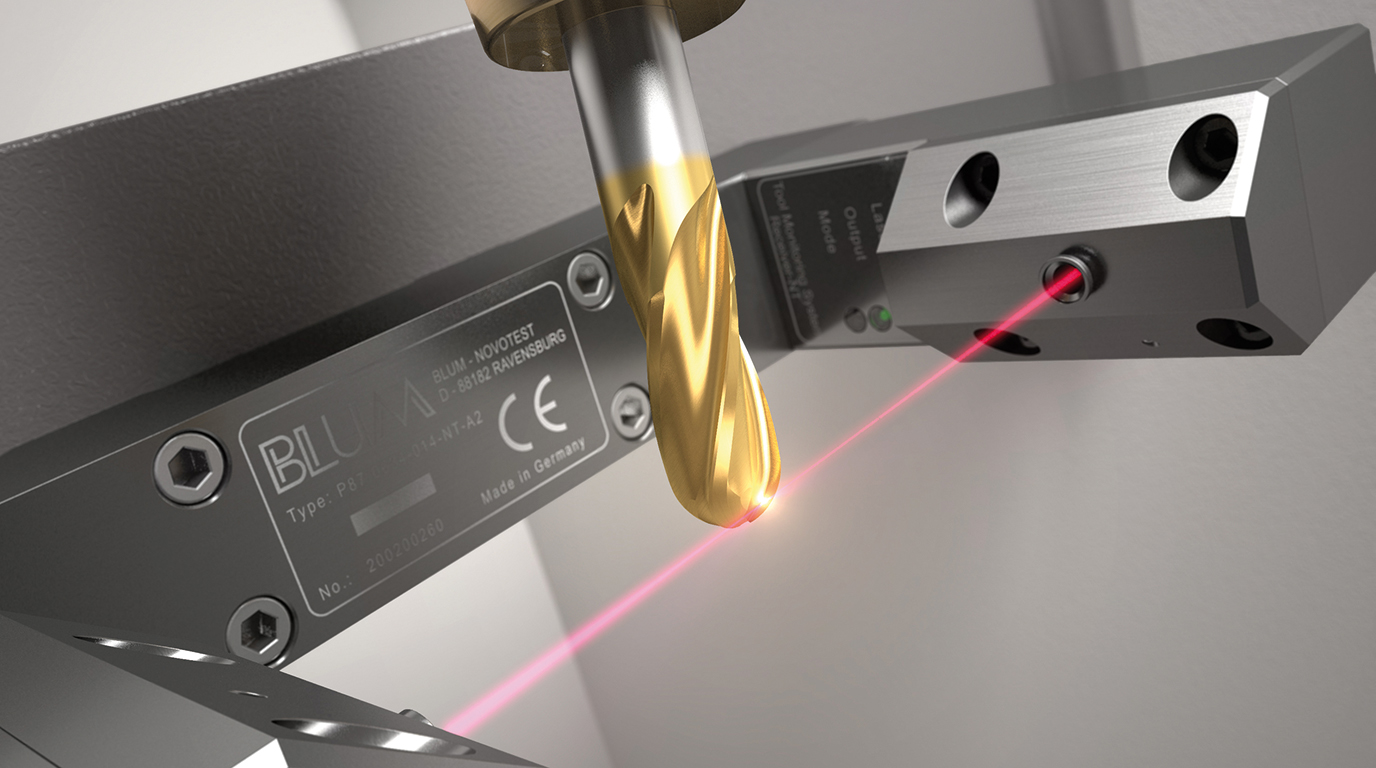

Laser tool measuring system “LaserControl Micro Compact NT”

-Non-contact type tool setting system for machine tools-

Risk of declining machining accuracy caused by wear and breakage of tool tips

The continued use of worn or damaged tool tips can lead to various problems such as poor workpiece accuracy, tool breakage and declining productivity, even if the damage is slight. Measurement of tool tips requires detachment of tools from a machine, cleaning up of chips, and re-attachment of tools. They take some extra time and work, which can cause operation errors and machining accuracy errors. The automatic detection of micro wear and breakage of tools during machining has been a big issue to improve productivity. Wear of an R-shaped tip of a ball endmill, which are mostly used on 5-axis machines, is difficult to measure with a contact-type measuring system, so the demand has been high for a highly accurate non-contact type measuring system.

This content is for members only