- Tips on machining 2017/04/24 UP

-

- Tag

-

- Chip disposal

What do you usually do when a product you are using at home is no longer needed? Most of you just throw it away as garbage.

Selling it to a recycling shop can be one of the best alternatives to throwing it away.

At metal-processing factories, large amounts of cutting chips are generated every day and are often disposed of as industrial waste. These unwanted chips, however, can be transformed into profitable products if processed properly. In this article we will introduce an example of the profitable use of chips in our group company which manufactures aluminum automotive parts in mass-production lines.

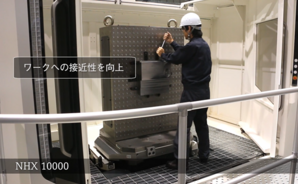

This factory runs 24 hours a day on a 3-shift system to machine aluminum die casting (ADC) on 60 machining centers, and discharges approximately 13 tons of chips every month. Focusing on monthly factory expenses, the coolant purchase cost is 1.13 million yen and waste oil disposal cost 175,000 yen. Meanwhile, unnecessary chips can be sold at 1.4 million yen, meaning that it can cover nearly all of these expenses.

This content is for members only