- Tips on machining 2017/04/04 UP

-

- Tag

-

- Milling

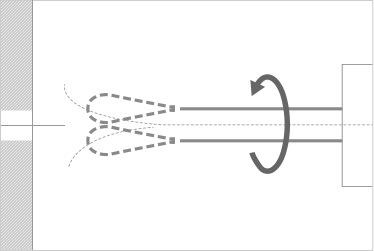

Deep hole drilling generally requires high accuracy in circularity, straightness and positional accuracy. Also, it is quite difficult to achieve both machining efficiency and machining accuracy because the deeper and thinner the hole, the lower the rigidity of the drill, which causes the drill to bend during machining. The difficulty of drilling is often indicated by the ratio of the hole diameter (D) to the hole depth (L), and this is called “L/D” (L by D) or an aspect ratio.

This article discusses the tips on deep hole drilling with L/D 10 or larger.

The quality of deep hole drilling is usually determined by how well the hole entrance is machined. In particular, the diameter, depth, and center angle of the guide hole as well as how to approach the guide hole are the keys to high-quality deep hole drilling.

Tool deformation (bending) inevitably occurs due to insufficient tool rigidity, long overhang and differences in the tool mounting position. So, particular attention should be paid to the drilling conditions and tool paths when the tool engages the workpiece at each depth.

This content is for members only