- Tips on machining 2018/07/09 UP

-

- Tag

-

- Milling

- Finishing

Key requirements for successful finishing operation are “dimensional accuracy” and “surface roughness”, as well as “stability (or repeatability of machining accuracy)” in case of mass-production. Many customers, however, find it challenging to achieve required dimensional accuracy, surface roughness, and stability with an end mill.

3 main obstacles to achieve required dimensional accuracy, surface roughness, and stability are: 1) wear of cutting edge, 2) deflection of an end mill, and 3) chatter vibrations. In other words, avoiding these problems or predicting them and taking appropriate countermeasures in advance will greatly contribute to reduction of machining time.

In this article, we would like to provide some solutions for the 3 major problems of finishing operation by an end mill.

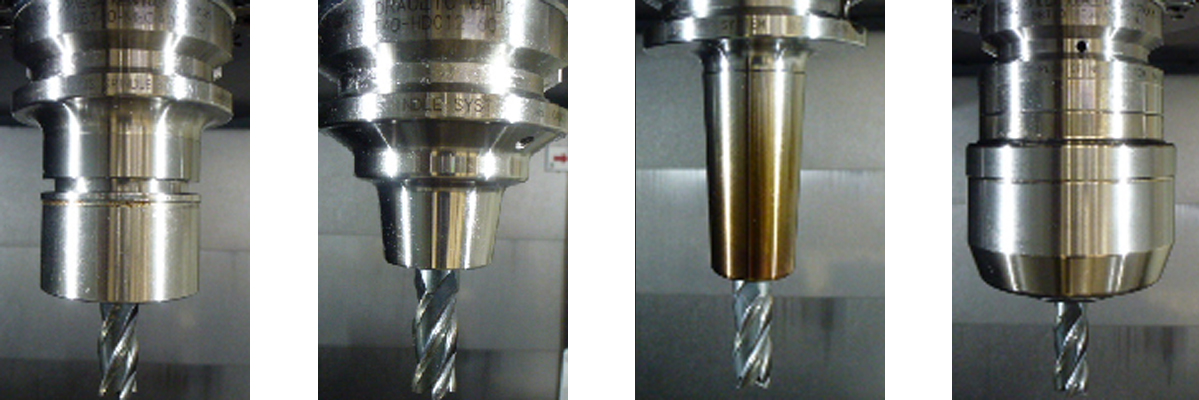

Variation of tooling to hold an end mill

From left to right: collet chuck, hydro chuck, shrink-fit chuck, milling chuck

This content is for members only