- Tips on machining 2017/07/05 UP

-

- Tag

-

- Coolant

- Chip disposal

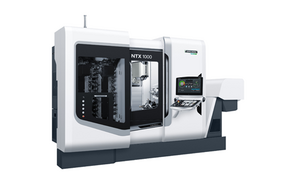

Reducing machining cost is a perennial issue for manufacturing, and automation and high-efficiency machining have been proposed as effective solutions for that purpose. Ideally, these two solutions should be implemented in combination to achieve cost reduction, but doing so is not easy as it sounds. However, high-pressure coolant may shed new light on this challenging issue.

In this article we will discuss the role of the high-pressure coolant and its recent trend with a focus on automation.

One of the main factors hindering automation is cutting chips. Long, continuous chips tend to get tangled in the workpiece and/or the tool and need to be removed manually, making automation difficult to achieve.

A chip breaker is employed on the rake face of the tool to break chips into small pieces. However, the chip breaker cannot function well when sticky materials such as a low-carbon steel and aluminum alloy are machined, even if the machining is done with the appropriate feed and cutting depth.

This content is for members only