- Tips on machining 2016/09/26 UP

-

Tips on machining vol.1

Tips on chucking easily-deformed workpieces

-How to hold low-strength whorkpieces-

- Tag

-

- Fixture/chuck

When a workpiece is machined on a turning center (lathe), a fixture called “chuck” is used to hold the workpiece. The chuck holds/releases the workpiece by closing/opening its jaws. There are several types of jawed chucks, which are differentiated by what types of power they use to open/close the jaws: some use a mechanical means such as a screw, taper or disc spring, and some use the diaphragm method (a mechanism which utilizes a fluid) including a hydraulic or pneumatic system, and others rely on magnetic or vacuum force.

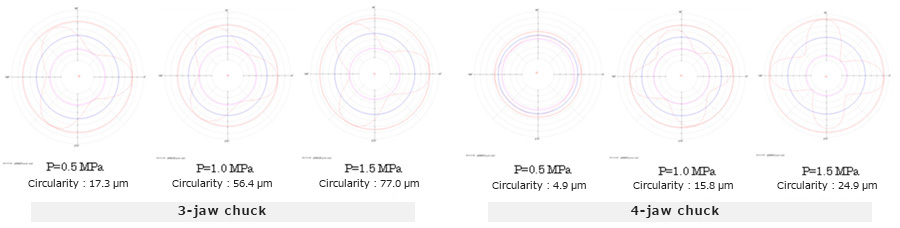

Among them, the hydraulic chuck is the most commonly used. However, it has also a disadvantage: excessive gripping force causes workpiece deformation, which consequently leads to the decrease in circularity. This is much more likely to occur if a hollow, thin-walled workpiece is chucked. For instance, when a hollow, thin-walled workpiece is held in a three-jaw chuck, the points where the jaws grip get dented, causing the workpiece to have a triangular cross-section (see Figures).

Figures: Comparison of I.D. circularity of hollow workpieces (by number of jaws)

This content is for members only