- Masterpiece in the world 2020/03/11 UP

-

Masterpiece in the world #30

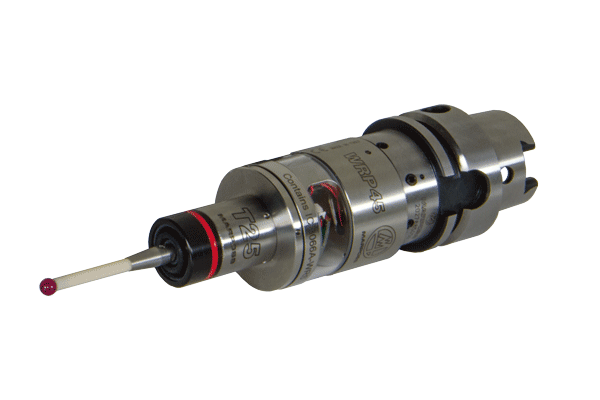

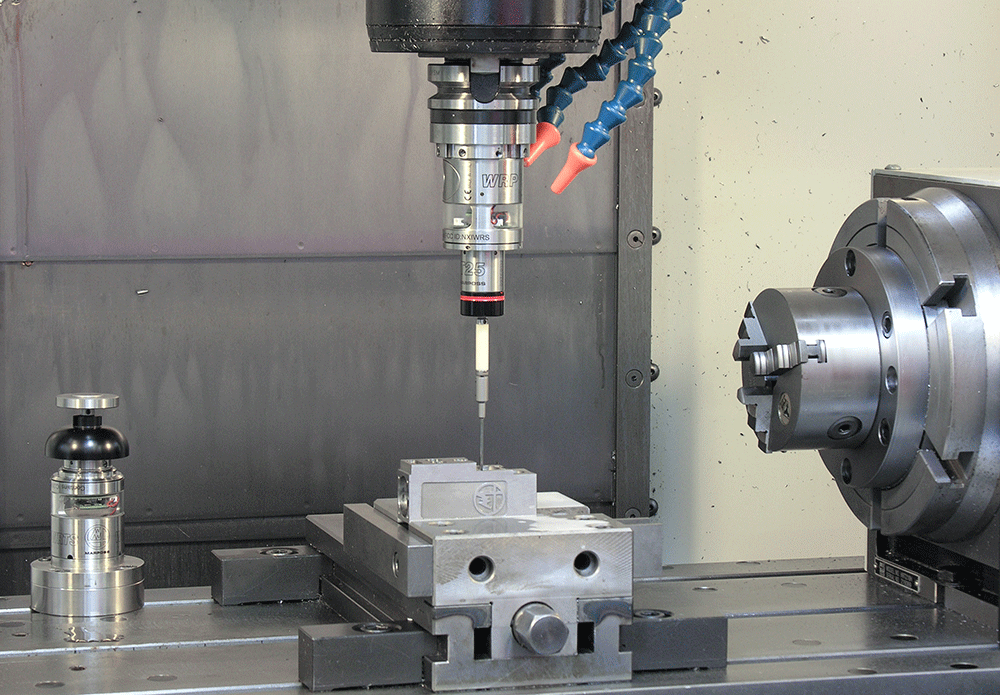

High-accuracy measurement using probe with original structure

“Worldwide wireless touch probe system WRS”

- Tag

-

- On-machine measuring system

- Peripherals

- Setup time reduction

It is important for operators to measure workpieces, tool length and tool diameters, and check tool damage and wear to ensure highly accurate and safe machining. However, manual measurement can take time and cause variation in accuracy according to the operator’s skill level.With automatic measurement, measuring time can be short compared to manual measurement, and accuracy variation is less likely to occur. On the other hand, when complex-shaped workpieces are measured, automatic measurement can take time, too. Besides, accuracy can be lower when a long stylus is used.Some shop owners may have problems such as radio frequency interference and time-consuming paring work. This time we will introduce the Marposs’s worldwide wireless touch probe system WRS.

Marposs’s original and special probe and the modular structure enable flexible measurement of complex-shaped workpieces

This content is for members only