- Masterpiece in the world 2018/05/10 UP

-

Masterpiece in the world #20

A small-sized, cost-efficient and eco-friendly insert with maintained performance-level – “ISO Eco Turn”

- Tag

-

- Tool

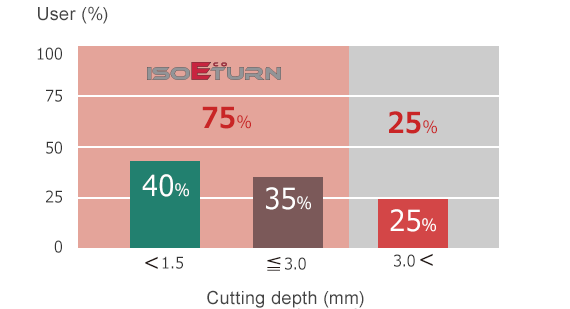

75% of conventional turning users cut 3mm deep or less (see Figure 1). However, one might find it difficult to secure an optimized-sized insert for the shallower cutting, and often have no choice but to use a bigger one.

In that case, the solution is to use a small-sized insert. However, smaller ones are usually thinner and therefore more easily broken, and the downsized breakers might deteriorate chip-processing efficiency.

Tungaloy’s eco-friendly insert “ISO Eco Turn” solves these problems in conventional turning machining, while maintaining cutting performance of a standard product.

Figure 1: Turning-machining users by cutting depth (according to Tungaloy’s survey)

A standard-sized insert is not cost-/space-efficient, while a small insert has issues in breakability and chip-processing

1.Breakage-resistance

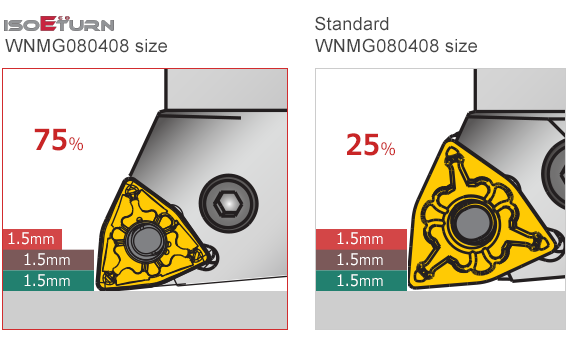

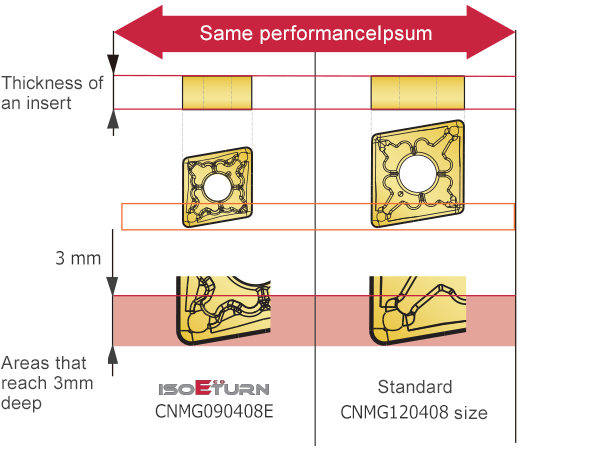

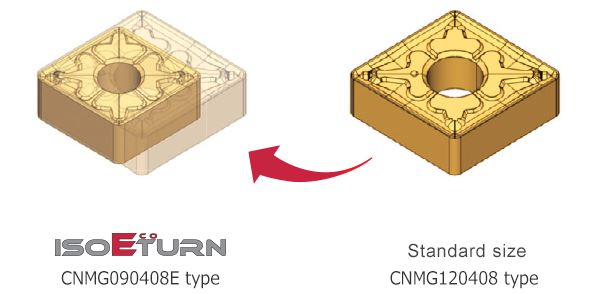

An insert’s thickness impacts the insert’s breakability. That is why “ISO Eco Turn” has the same thickness with a standard insert to secure the equivalent robustness. Compared to a standard CNMG120408 type, “ISO Eco Turn” is smaller in size, but the thickness is not different (see Figure 2 and 3). This feature greatly helps “ISO Eco Turn” achieving the same cutting performance as standard ones.

Figure 2: ISO Eco Turn technical features

Figure 3: Comparison of ISO Eco Turn and a standard-sized insert

2.Chip-processing efficiency

Another issue as important as breakage-resistance is chip-processing efficiency. Normally a smaller-sized insert has a smaller breaker, which often results in lower chip-processing performance.

However, “ISO Eco Turn” has the same breaker specifications as a standard insert for the targeted cutting-depth range under 3mm. One can replace a standard insert with “ISO Eco Turn” and still enjoy the same chip-processing efficiency and cutting capability.

3.Eco-friendliness

“ISO Eco Turn” uses less carbide compared to a conventional insert thanks to its smaller size. In that sense, ISO Eco Turn is an eco-friendly insert series with a mitigated impact on the environment, given the recent scarcity of rare metal, especially of Tungsten in the cutting tool industry. Also, the much-downsized insert is set at lower price range than a standard one, leading to tool cost reduction in production lines.

The product lineup includes CVD-type T9100 series for steel material, cermet-type NS/GT9530, CVD-type T5100 series for cast irons, CVD-type T6100 series for stainless, PVD-type AH600 series, PVD-type AH8000 series for hard-to-cut material/stainless and PVD-type AH120 for universal applications.

The environmental-friendly “ISO Eco Turn” will benefit your factory with lower tool cost and maintained operability and cutting performance.

| Tungaloy Corporation Locations: 11-1, Yoshima Industrial Park, Iwaki City, Fukushima Tel: 0120-401-509 Contact via: https://www.tungaloy.com/contact/ |

The article introduces the DMG MORI selection of masterpiece equipment in the world.

Please visit our DMG MORI showroom to see the products in the article.

*As some equipment is displayed for a limited time only, please check with us in advance.